A raw material grinding and stirring device for ceramic products

A technology for stirring devices and ceramic products, applied in clay preparation devices, chemical instruments and methods, clay processing equipment, etc., can solve problems affecting the use effect, unsatisfactory powder uniformity, etc., and achieve the effect of improving the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

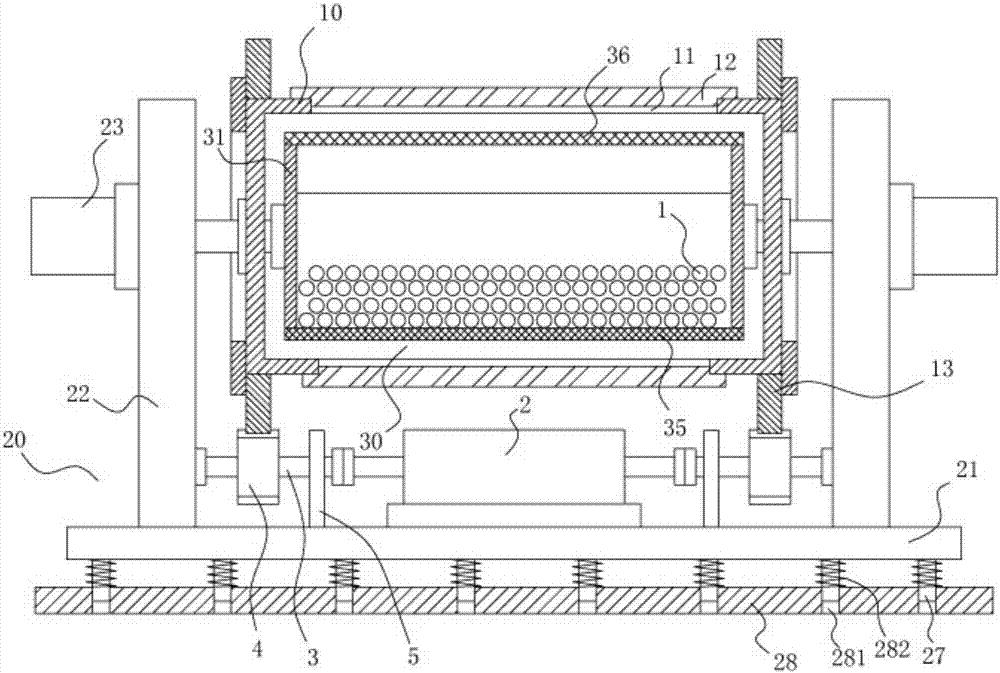

[0017] Example: see Figure 1 to Figure 2 As shown, a raw material grinding and stirring device for ceramic products includes a horizontally arranged grinding outer barrel body 10 and a frame body 20, an inner barrel body 30 is inserted in the grinding outer barrel body 10, and the frame body 20 includes a bottom connecting plate 21 , the top surface of the bottom connecting plate 21 is fixed with two support plates 22, and the drive motor 23 is fixed on the two support plates 22, the output shaft of the drive motor 23 passes through the support plates 22 and is hinged on the left and right sides of the grinding outer barrel On the first end plate, the end of the output shaft of the drive motor 23 is fixed on the two side end plates 31 of the inner barrel body 30;

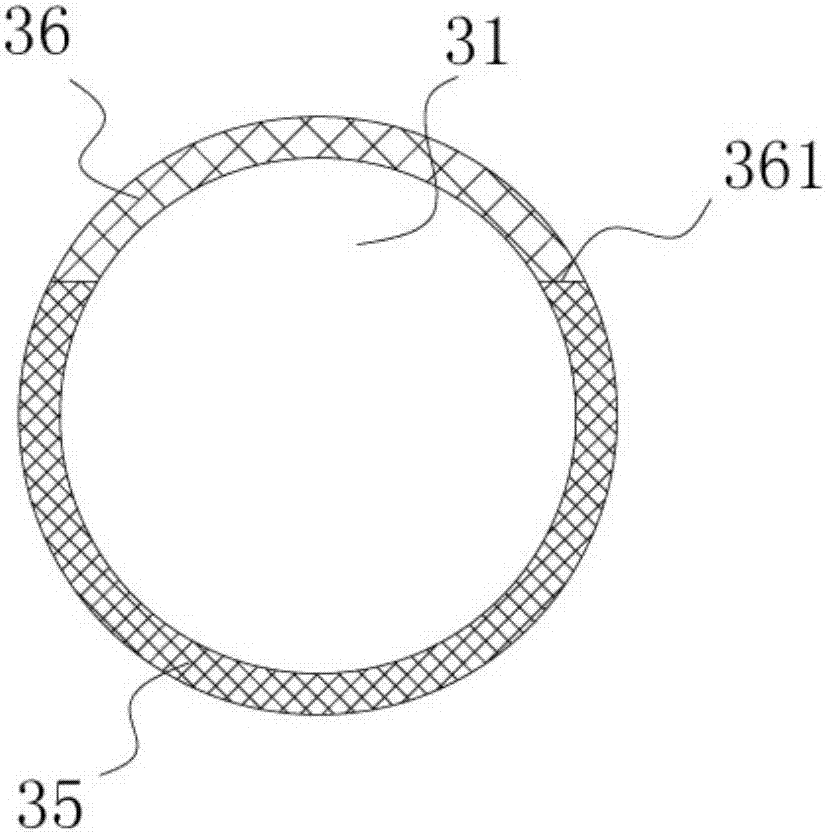

[0018] The inner barrel body 30 includes two side end plates 31, an arc-shaped side wall 35 and an upper arc-shaped cover plate 36, and the inner side walls at both ends of the arc-shaped side wall 35 are fixed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com