Blind window opened and closed through temperature control and engine compartment structure

A shutter and temperature-controlled room technology, applied in the field of temperature-controlled opening and closing shutters and engine room structures, can solve the problems of difficult cold start, low work efficiency, affecting the start and work efficiency of the whole machine, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical scheme of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

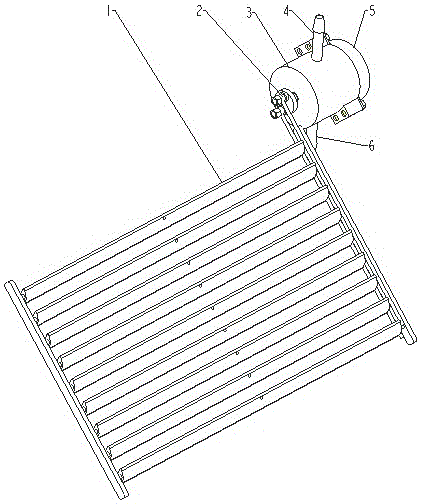

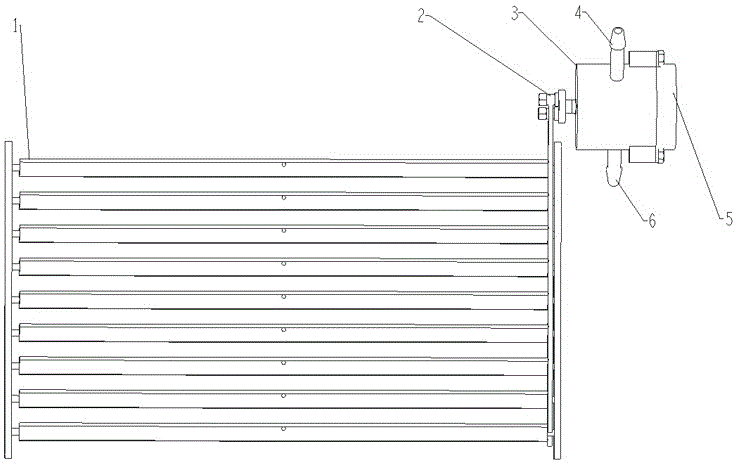

[0021] A temperature-controlled shutter, such as Figure 1-4 As shown, the louver body 1 is included, and a temperature control device for controlling the opening angle of the louver body 1 is included. The louver body 1 is what we usually call a louver without automatic opening and closing function.

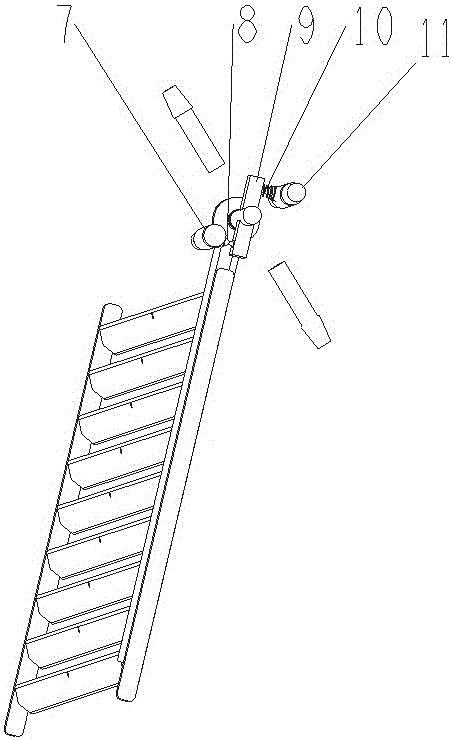

[0022] The temperature control device includes a rotating mechanism 9 connected to the shutter body 1, the rotating mechanism 9 is provided with a cross bar, for example, the rotating mechanism 9 is cross-shaped or T-shaped, and one end of the cross bar is provided with a rotatable first paraffin wax The other end of the tube 7 is provided with a ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com