Vibration absorption and de-noising improved structure of motor rotor

A vibration and noise reduction, motor rotor technology, applied in the direction of the casing/cover/support, electrical components, electromechanical devices, etc., can solve problems such as unfavorable quick installation, waste of materials, difficult control, etc., to reduce the vibration caused by itself. Effects of damage, noise reduction, simplified operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

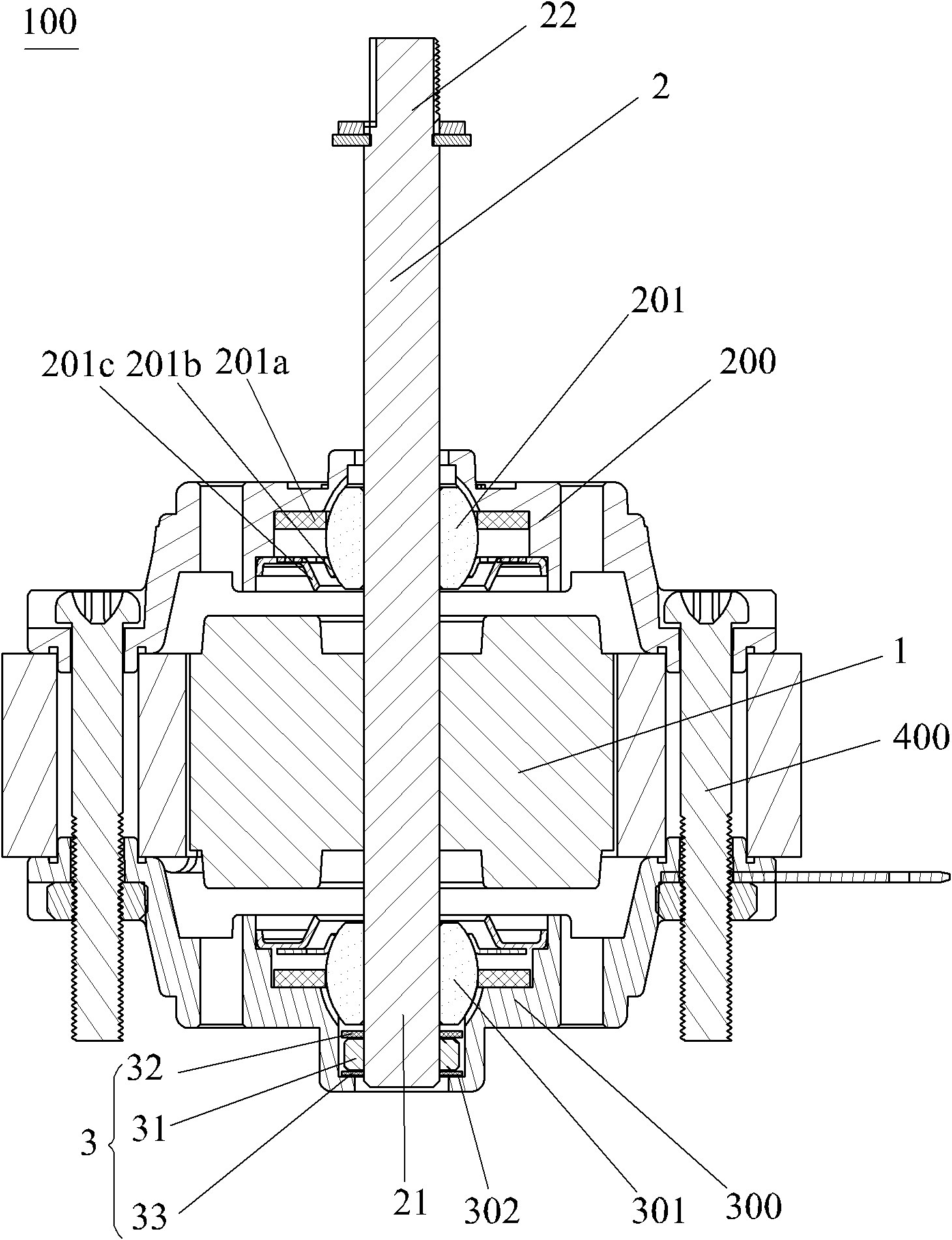

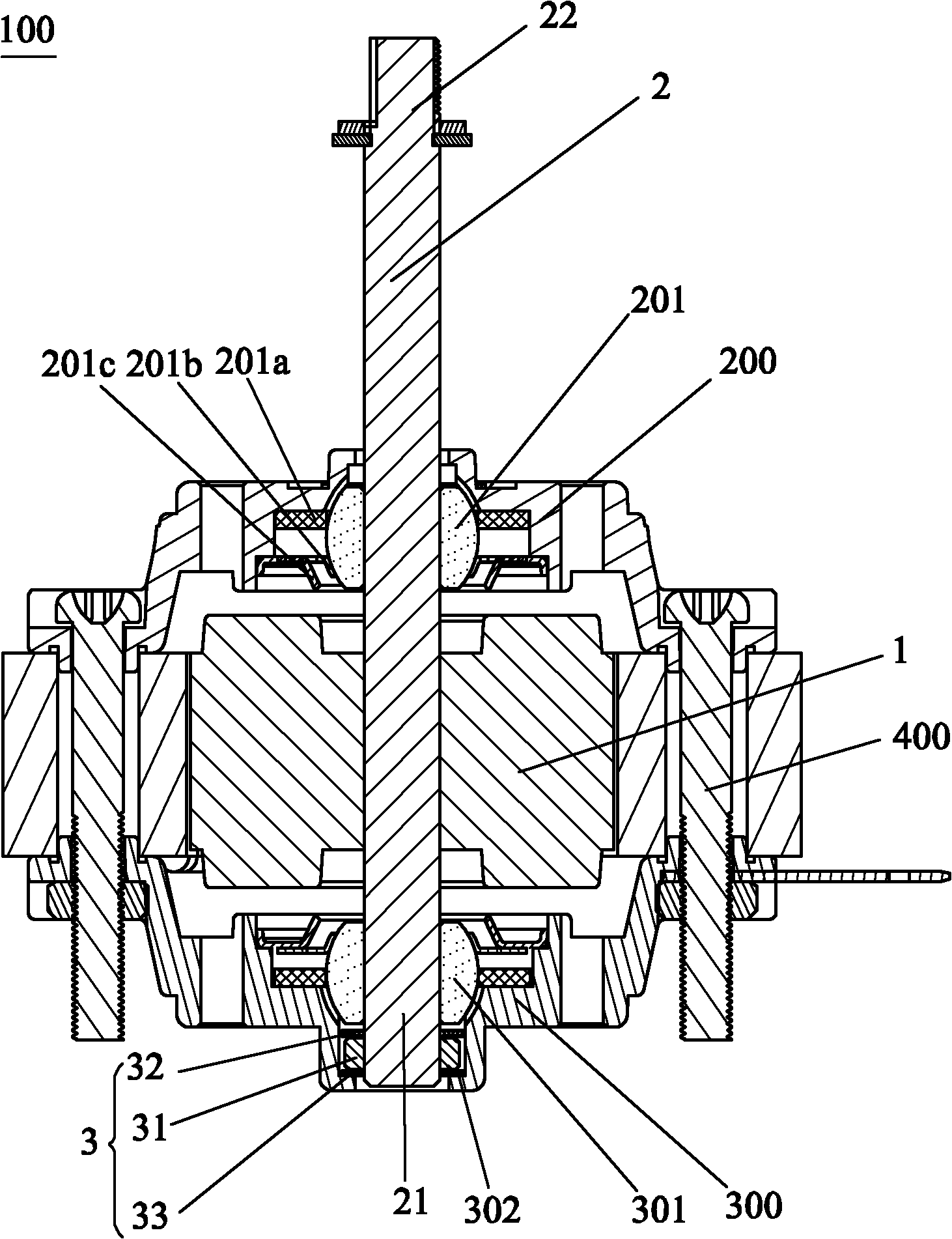

[0016] Embodiments of the present invention will now be described with reference to the drawings, in which like component numbers represent like components. As mentioned above, the present invention provides an improved structure for vibration reduction and noise reduction of the motor rotor, which uses less materials, has low cost, and is quick to install, can be positioned and installed in one step, and can effectively reduce the vibration generated by the rotor rotation. Damage yourself and reduce noise.

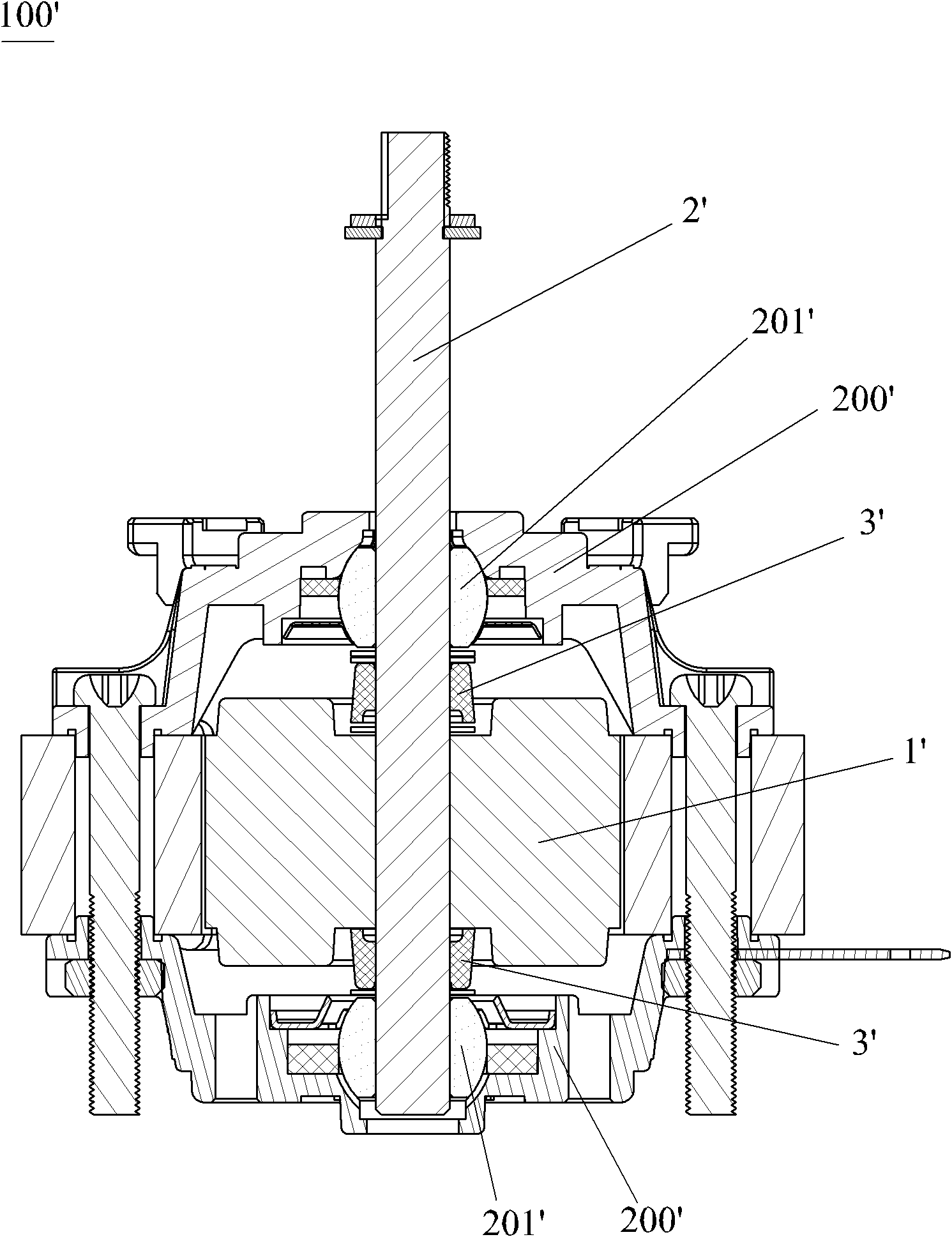

[0017] like figure 2 As shown, the improved structure 100 for vibration reduction and noise reduction of the motor rotor of the present invention is installed between the end faces of the two bearings 201, 301 in the upper and lower rotor brackets 200, 300 and the stator (not shown in the figure) to form a motor, including the rotor 1 and the Rotating shaft 2, the rotor 1 is sleeved and fixed with the rotating shaft 2, and one end 21 of the rotating shaft 2 passes throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com