Telescopic pressing sizing plate

A stereotyped plate, one-piece technology, applied in washing devices, wrinkle-removing and flattening equipment, textiles and papermaking, etc., can solve the problems of waste and poor versatility, and achieve the effect of strong versatility and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

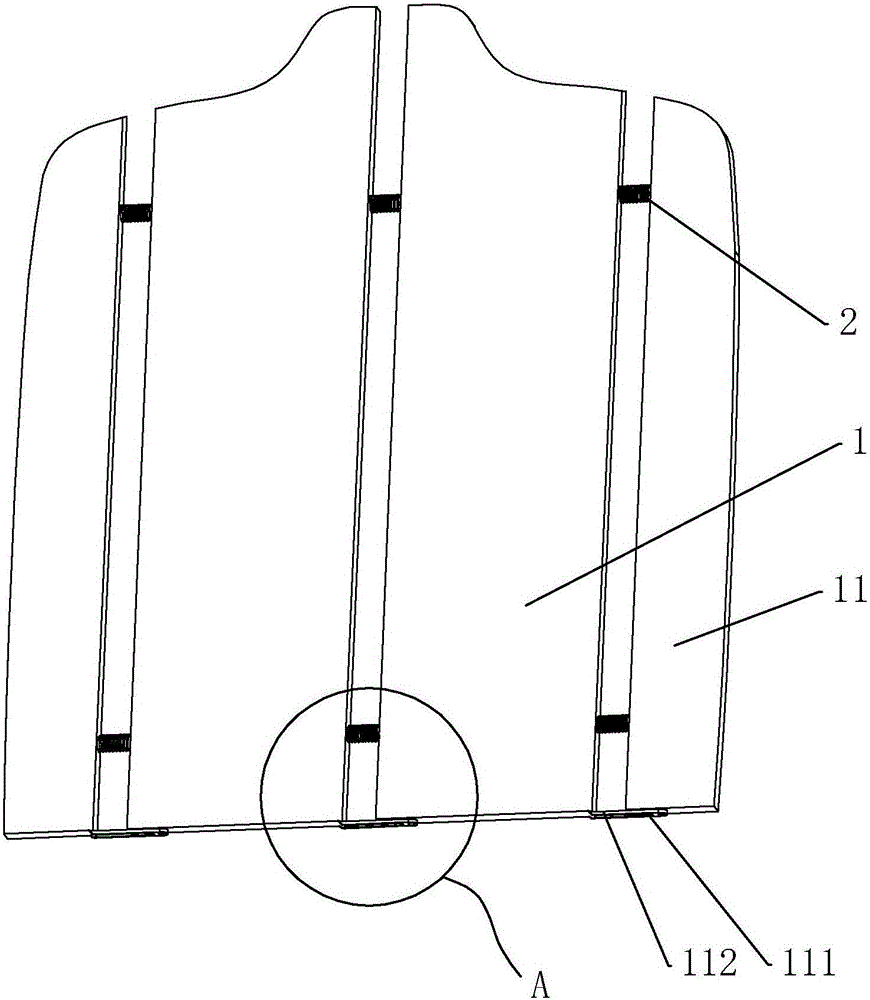

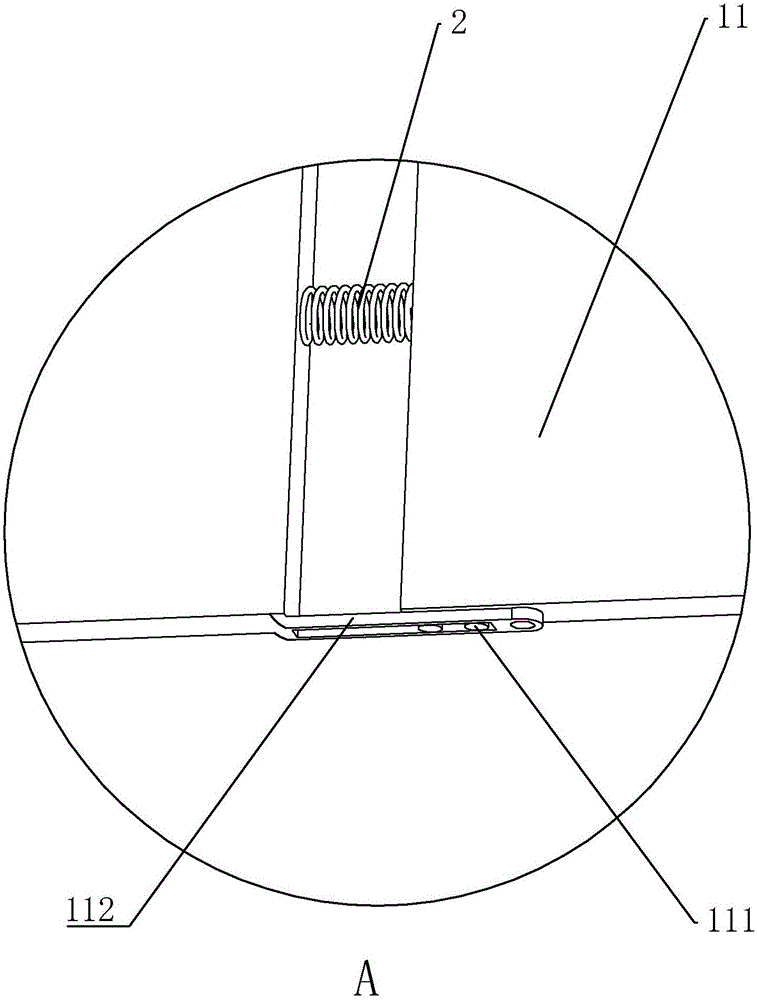

[0012] refer to Figure 1 to Figure 2 The embodiment of a retractable pressing and shaping board of the present invention will be further described.

[0013] Such as figure 1 and 2 As shown, the sizing plate body 1 is divided into several sizing plate units 11 in the horizontal direction, and the adjacent sizing plate units 11 are connected by springs 2 in a compressed state. When the size of the clothes is large, the bottom of the sizing plate unit 11 is opened The buckle 112 at the end, under the elastic force of the spring 2, the distance between the adjacent shaped plate units 11 becomes larger, and then the limit block 111 close to the spring 2 is selected to cooperate with the buckle 112 to limit the position, and the distance between the adjacent shaped plate units 11 The distance between them becomes larger and the overall width of the shaping plate becomes larger; when the size of the clothes is small, open the buckle 112, overcome the elastic force of the spring 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com