Plate spring, plate spring set and compressor

A technology of leaf springs and elastic arms, applied in the direction of springs, spring components composed of several springs, springs/shock absorbers, etc. Problems such as component quality, to achieve the effect of small equivalent quality, reduce product quality, and increase product life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

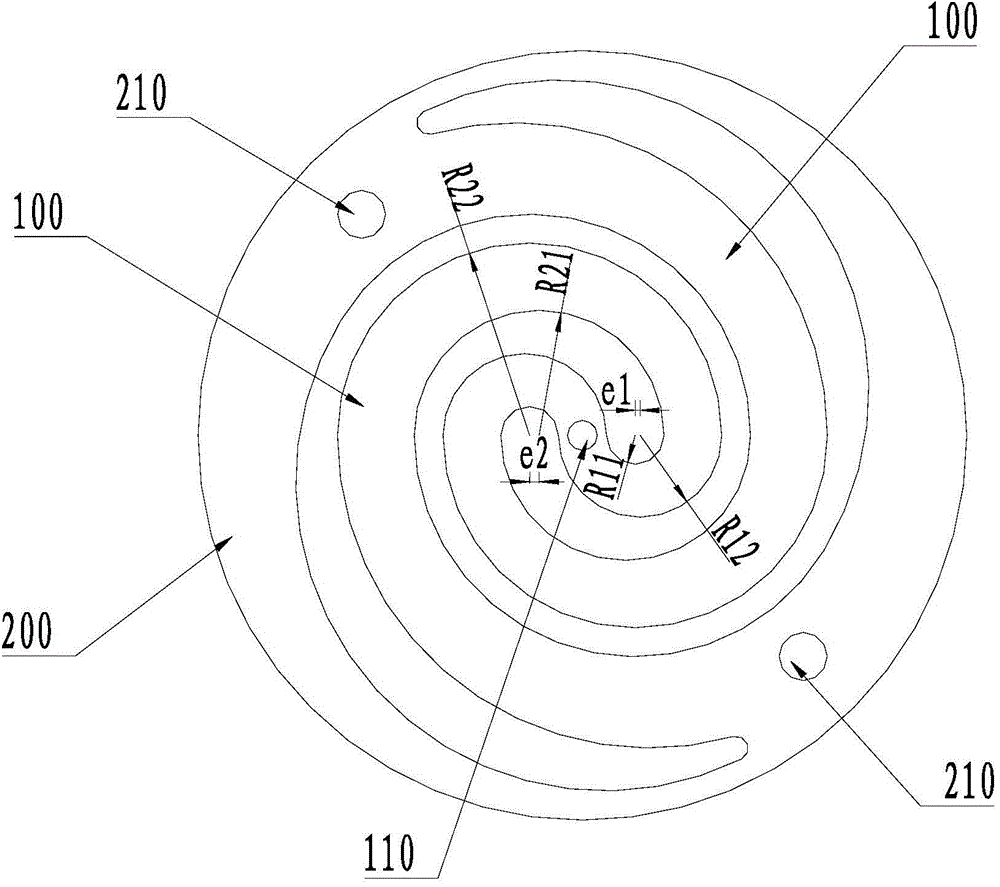

[0051] Embodiment one, see Figure 4 ;

[0052] The leaf spring in this embodiment is a leaf spring 300 with multi-circular arms of equal width. The equal-width multi-circle arm leaf spring 300 in this embodiment includes two axially symmetrical elastic arms 310, 320, and a circular fixing ring 330, and the fixing ring 330 is provided with an outer fixing hole 331 for corresponding installation The structure is fixed.

[0053] The two elastic arms 310 and 320 have the same structure, and the width from the start end to the end is constant, that is, the width is constant, and both are formed by tangent to three pairs of concentric or eccentric arcs. 3 pairs of concentric arcs or eccentric arcs gradually increase in radius from inside to outside, and their centers are all on the same straight line. The initial ends of the two elastic arms 310, 320 are tangent, and an internal fixing hole 340 is provided at the joint between the initial ends, and the two elastic arms 310, 320 ...

Embodiment 2

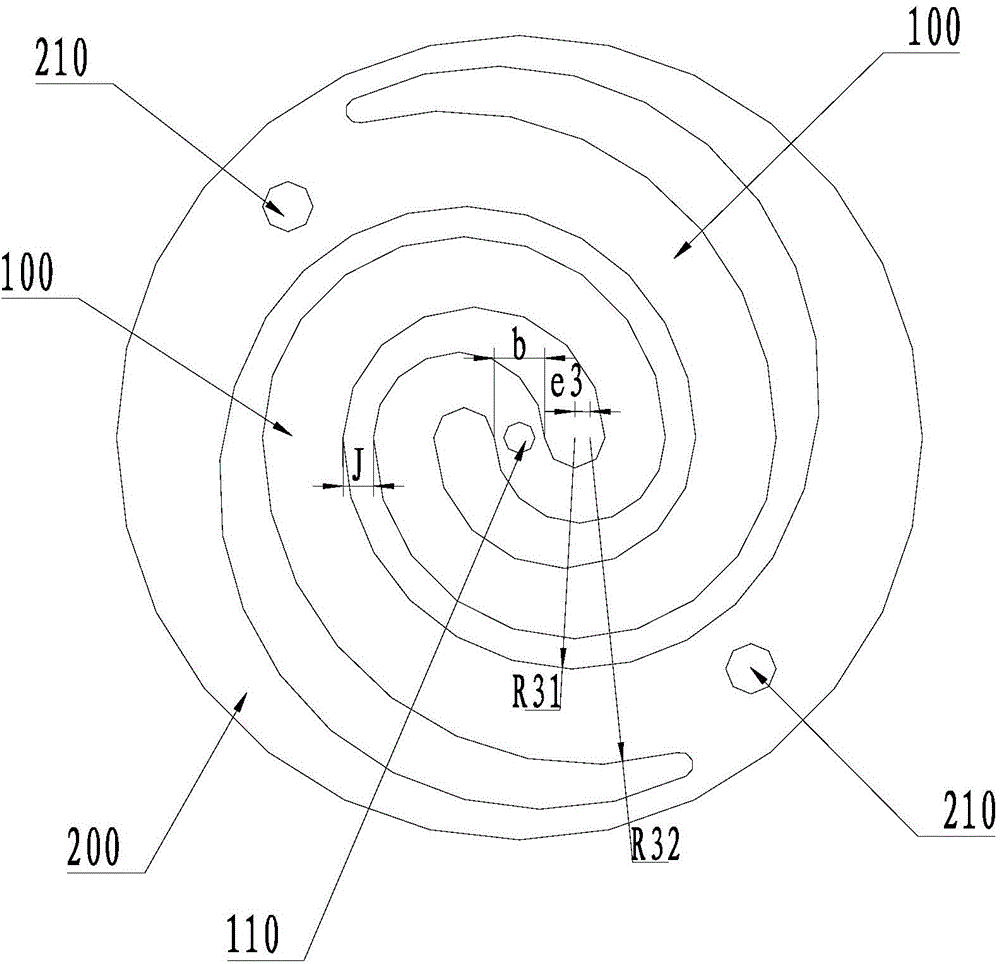

[0055] Embodiment two, see Figure 5 ;

[0056] The leaf spring in this embodiment is a multi-circle arm leaf spring 400 of unequal width. The unequal-width multi-circular arm plate spring 400 in this embodiment includes two axially symmetrical elastic arms 410, 420, and a circular fixing ring 430. The fixing ring 430 is provided with an outer fixing hole 431 for matching with the corresponding The installation structure is fixed.

[0057] The two elastic arms 410 and 420 have the same structure, gradually widen from the center to the outside (from the beginning end to the end), and are formed by three pairs of concentric or eccentric arcs tangent to each other. 3 pairs of concentric arcs or eccentric arcs gradually increase in radius from inside to outside, and their centers are all on the same straight line. The initial ends of the two elastic arms 410 , 420 are tangent, and an internal fixing hole 440 is provided at the connection between the initial ends, and the two el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com