Electronic controlled hydraulic mount

An electronically controlled hydraulic and suspension technology, applied in the field of auto parts, can solve the problems of not meeting the shock absorption requirements, high cost, complex structure, etc., and achieve the effect of simple structure, low cost and good reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

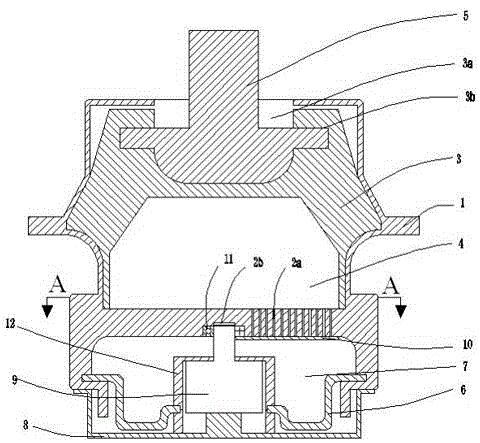

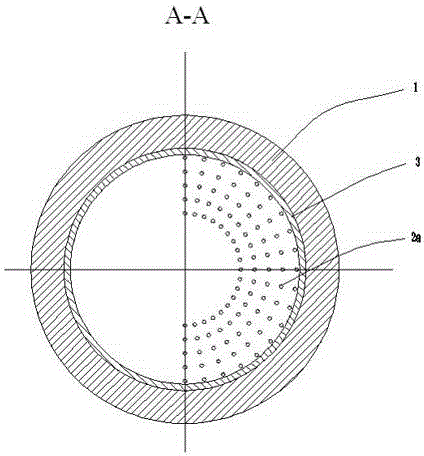

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

[0015] See figure 1 and figure 2 : An electronically controlled hydraulic mount, comprising a shell base 1, a rubber spring 3, a metal frame 5 and a base film 6, the shell base 1 is divided into two cavities up and down by a partition 2, and the partition 2 is located on the shell base 1, and the partition 2 is integrated with the shell base 1, and a rubber spring 3 is arranged in the upper cavity of the shell base 1, and the rubber spring 3 and the partition 2 form a closed upper liquid chamber 4 , a metal skeleton 5 is fixed on the rubber spring 3, and the upper end of the metal skeleton 5 protrudes from the shell base 1, that is, a skeleton installation hole 3a is opened in the center of the upper part of the rubber spring 3, and a skeleton installation hole 3a is inside the skeleton installation hole 3a. There is an annular card slot 3b, the section of the metal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com