Structure of hybrid multi-core planar optical waveguide and coupling structure and coupling method thereof

A planar optical waveguide and coupling structure technology, applied in the field of optical waveguide coupling, can solve the problems of high packaging cost, difficulty in large-scale integration, complex process, etc., and achieve the effect of improving coupling efficiency and alignment tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

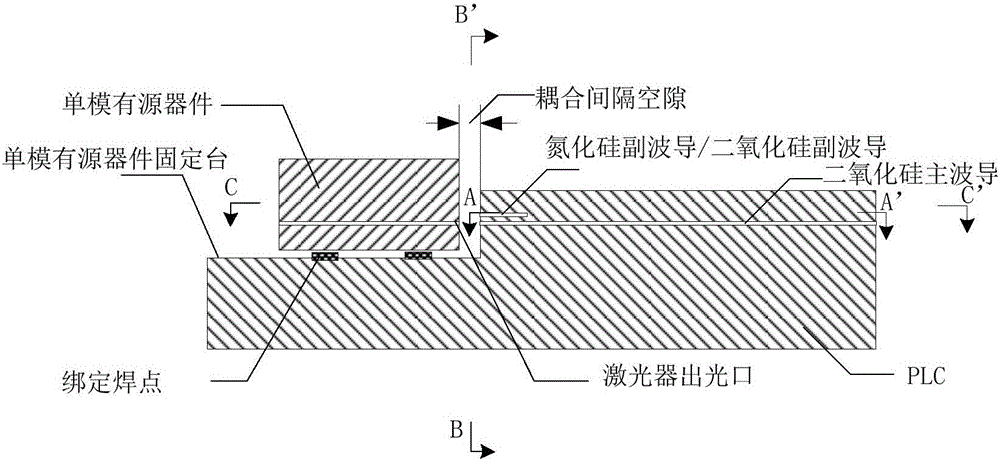

[0057] Embodiment 1 of the present invention provides a hybrid multi-core planar optical waveguide structure, such as Figure 1-4 The structure includes, specifically:

[0058] The planar optical waveguide includes a silicon dioxide main waveguide for transmitting optical signals, and a secondary waveguide for assisting light entering;

[0059] The secondary waveguide includes a silicon nitride secondary waveguide, and the silicon nitride secondary waveguide is in close contact with the silicon dioxide main waveguide.

[0060] Wherein, the silicon nitride secondary waveguide can be in various structural forms: for example, it is specifically a rectangular cubic structure, a positive ladder structure, an inverted ladder structure, and the like.

[0061] The hybrid multi-core waveguide proposed in this embodiment refers to adding a silicon nitride secondary waveguide other than the silicon dioxide main waveguide to the laser interface of the PLC to form a hybrid multi-core wave...

Embodiment 2

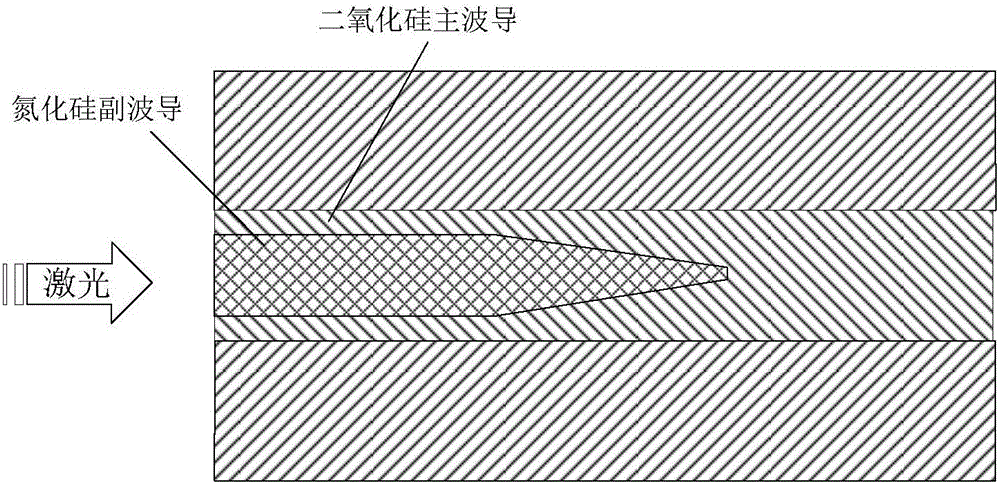

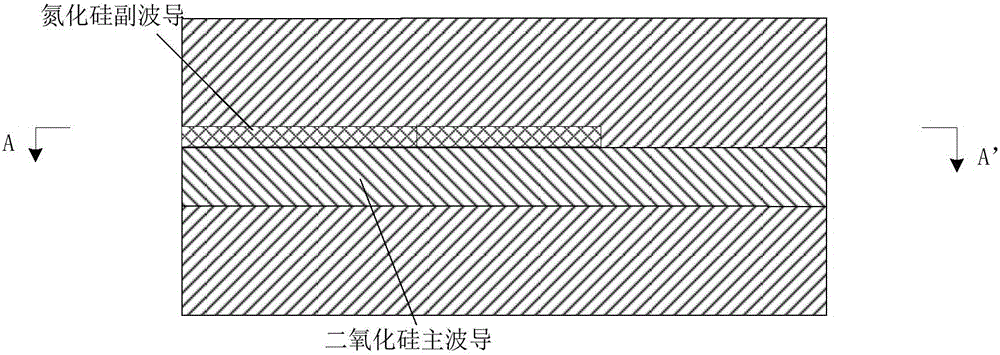

[0065] Based on the planar optical waveguide structure described in Embodiment 1, Embodiment 2 of the present invention specifically elaborates one of the optional sub-waveguide structures. Specifically, the sub-waveguide not only includes a silicon nitride sub-waveguide, but also includes Silica secondary waveguides, such as Figure 5 , Figure 6 , Figure 7 and Figure 8 As shown, the specific structure is described as follows:

[0066] The planar optical waveguide includes a silicon dioxide main waveguide for transmitting optical signals, and a secondary waveguide for assisting light entering;

[0067] Both the silicon nitride secondary waveguide and the silicon dioxide secondary waveguide are composed of a transition part and a cone part. The transition part is a rectangular cube extending toward the light transmission direction; A structure extending in the light transmission direction; wherein, the silicon nitride secondary waveguide is located on the upper surface o...

Embodiment 3

[0085] Based on the planar optical waveguide structure described in Embodiment 1, Embodiment 3 of the present invention specifically elaborates one of the optional secondary waveguide structures, such as Figure 10 , Figure 11 and Figure 12 As shown, specifically, the silicon nitride sub-waveguide is composed of two sub-sub-waveguides, wherein the first sub-sub-waveguide is located on the upper surface of the silicon dioxide main waveguide, and the second sub-sub-waveguide is located on the silicon dioxide The lower surface of the main waveguide.

[0086] In combination with the embodiment of the present invention, there is a preferred implementation solution, such as Figure 10 As shown, both the first sub-waveguide and the second sub-waveguide are composed of a transition part and a cone part, wherein the transition part is a rectangular cube extending toward the light transmission direction; wherein the cone part is the bottom surface and the transition part Convergenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com