Quantitative evaluation method for lateral sealing of faults

A quantitative evaluation and sealing technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of fault rock displacement pressure deviation, low evaluation accuracy, poor physical properties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] Provide the present invention in detail below:

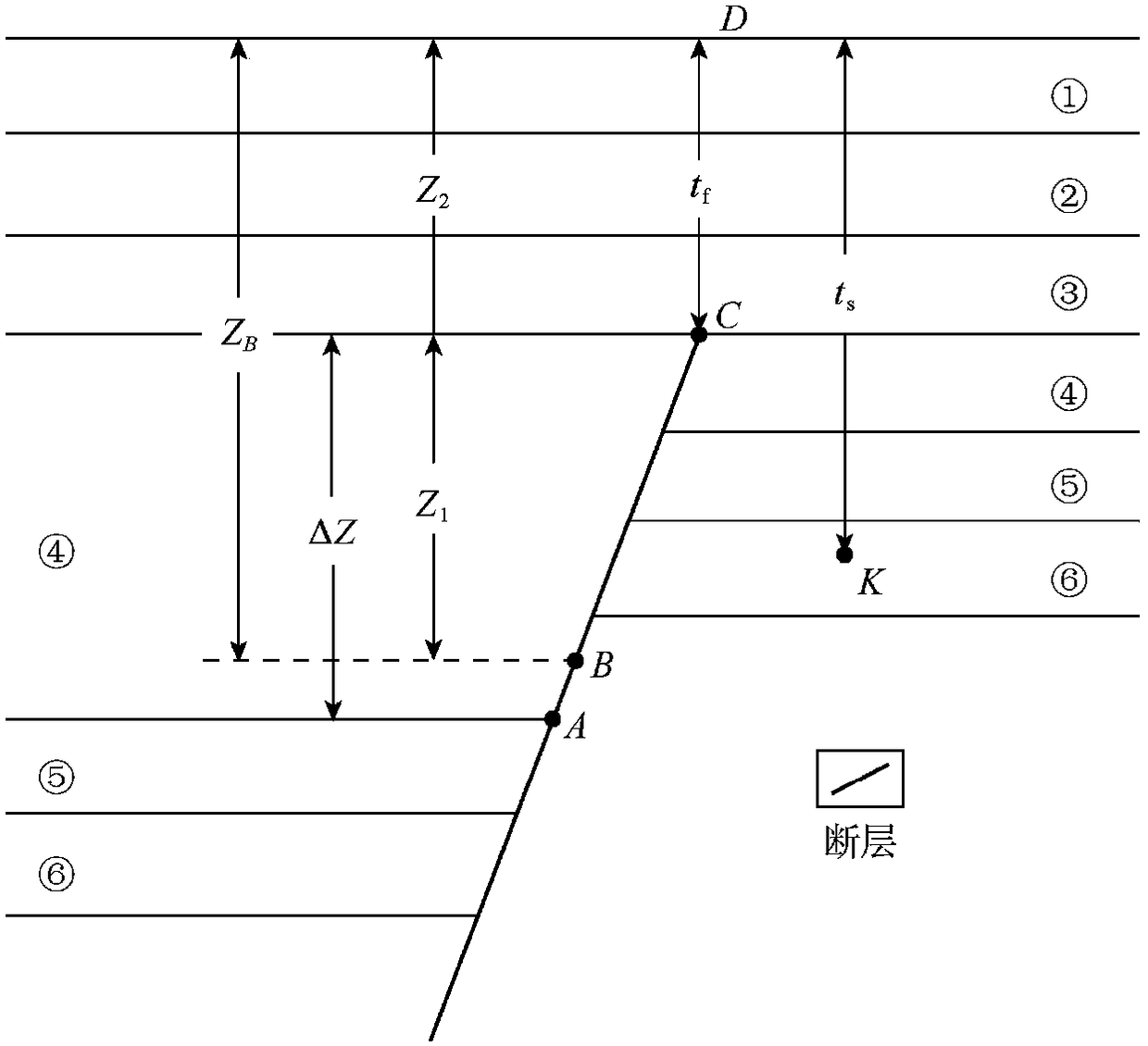

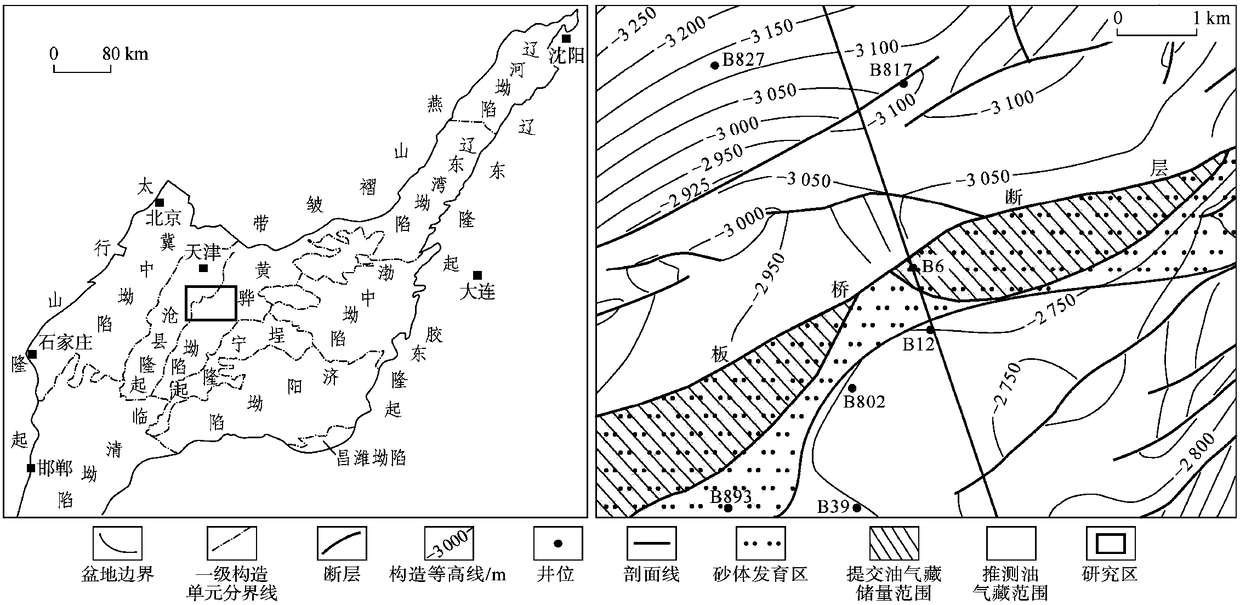

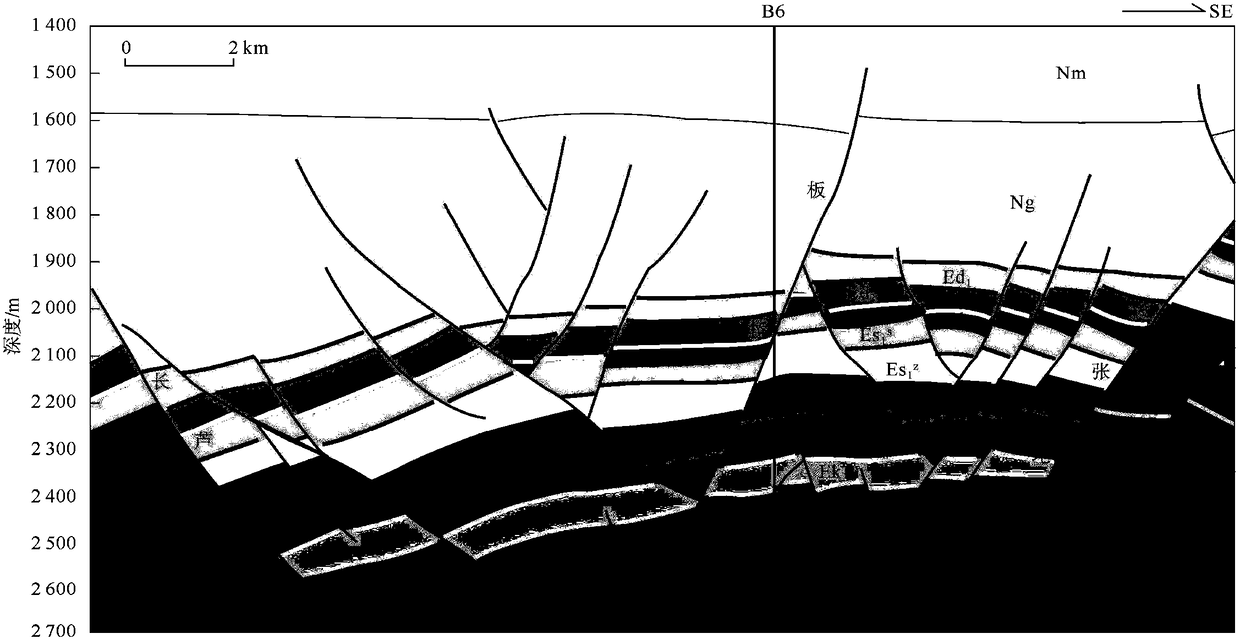

[0059] Firstly, the mechanism of fault lateral sealing and the influencing factors of displacement pressure are analyzed. Formation negative pressure or low pressure is often formed in the fracture space formed after fault activity, so that the formation water in the surrounding rock reservoir quickly enters the fracture and fills the pores of the fault debris filling, so that the fracture debris filling has a relatively low pressure compared with the surrounding rock. With large porosity and water saturation, the filling gradually discharges pore water under the action of positive pressure on the section, and slowly compacts to form diagenetic rocks, forming fault rocks. The evolution of fault clastic fillings to fault rocks is a process in which the porosity gradually decreases, the degree of diagenesis increases gradually, and the sealing ability gradually forms and becomes stronger. The sealing ability of fault filli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com