Test method for evaluating cement stabilized macadam skeleton structure

A cement-stabilized crushed stone and skeleton structure technology, applied in the direction of applying stable tension/pressure to test the strength of materials, preparation of test samples, weighing by removing certain components, etc., can solve problems such as structural damage of test pieces , to achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

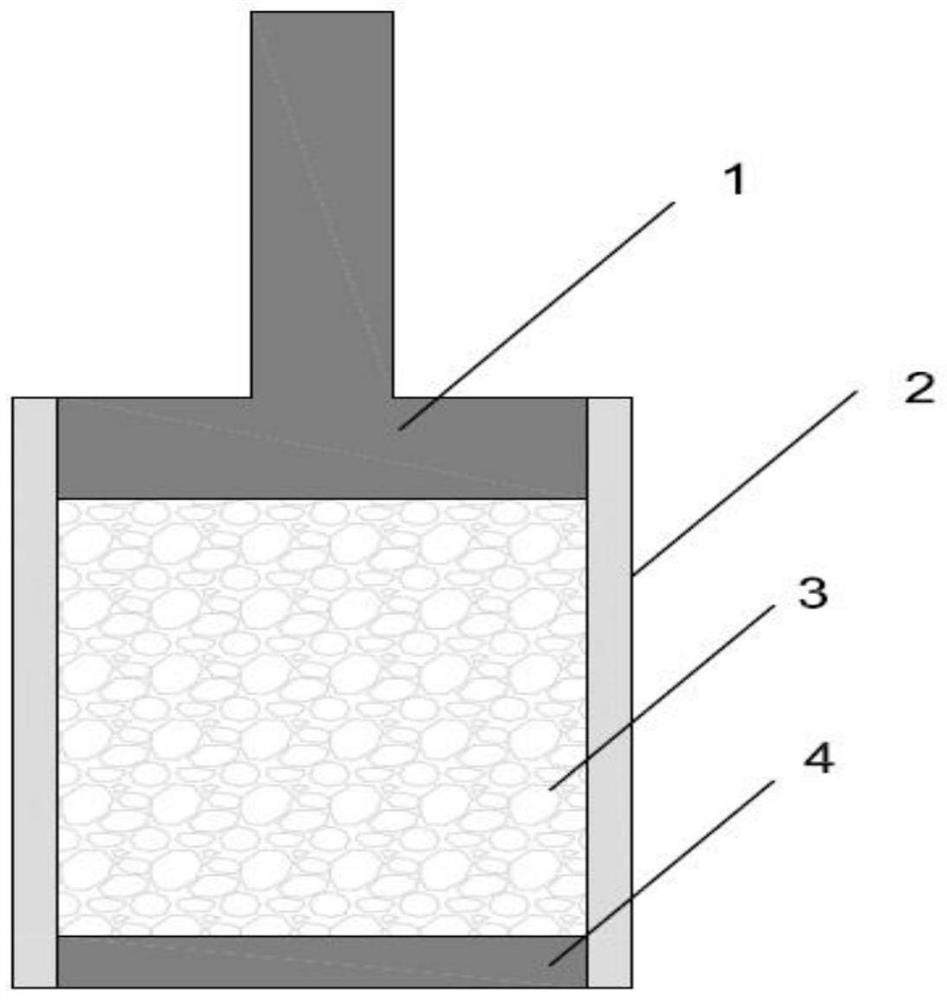

[0042] Embodiment 1: This embodiment is a kind of test process of evaluating cement-stabilized crushed stone skeleton structure evaluation, specifically comprises the following steps:

[0043] Step 1: According to the different gradation types designed, select 3 types of air-dried stones with different particle sizes, and the proportions of the 3 gradation particle sizes are shown in the following table:

[0044]

[0045] Mix each gradation of the air-dried stone to be tested, fully stir evenly, and the stirring time should not be less than 2min, for later use.

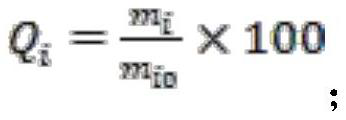

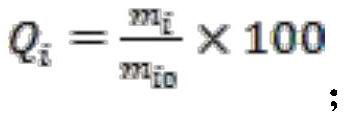

[0046] Step 2. Sieve each graded air-dried stone mixed sample with a standard sieve with a diameter of 19mm, 16mm, 13.2mm, 9.5mm and 4.75mm, and weigh the air-dried stone mixed sample to pass the corresponding standard Sieve mass m i0 , i is the particle size serial number of the standard sieve, i=1, 2, 3, 4, 5, record the passing rate of the air-dried stone mixed sample to be tested through the corresponding standa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com