Roll forming mechanism of dried soybean milk film rolls

A forming mechanism and technology of bean gluten, which is applied in the field of bean gluten rolling and forming mechanism, can solve the problems of time-consuming, insufficient contact with bean skin, etc., and achieve the effect of good taste, simple and reasonable structure, and sufficient contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below by means of specific embodiments:

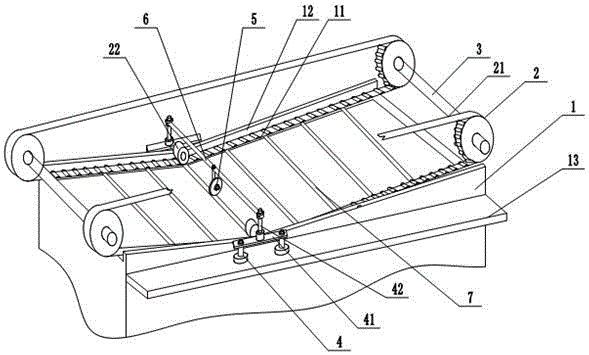

[0016] The reference signs in the accompanying drawings of the description include: soybean milk pot 1, V-shaped slope 11, protective plate 12, support platform 13, pulley 2, belt 21, auxiliary wheel 22, rotating shaft 3, lower column 4, support block 41, upper Column 42, pinch wheel 5, beam 6, rolling stick 7.

[0017] The embodiment is basically as attached figure 1 Shown:

[0018] The soya-bean tendon rolling forming mechanism in this program includes a soybean milk pot 1, a belt 21, a pulley 2, an auxiliary wheel 22, a driving device and a rotating shaft 3, and V-shaped inclined surfaces 11 are processed on both sides of the soybean milk pot 1, Two ends of the soybean milk pot 1 are respectively provided with a rotating shaft 3, and two pulleys 2 at the same end on both sides of the soybean milk pot 1 are respectively connected to the two ends of the rotating shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com