Peeling machine

A peeling machine and casing technology, applied in peeling utensils, household utensils, applications, etc., can solve the problems of time-consuming chefs or housewives, difficult skin removal with a knife, irregular shapes, etc., and achieve high peeling efficiency. , The product structure is simple, the effect of cleaning is convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

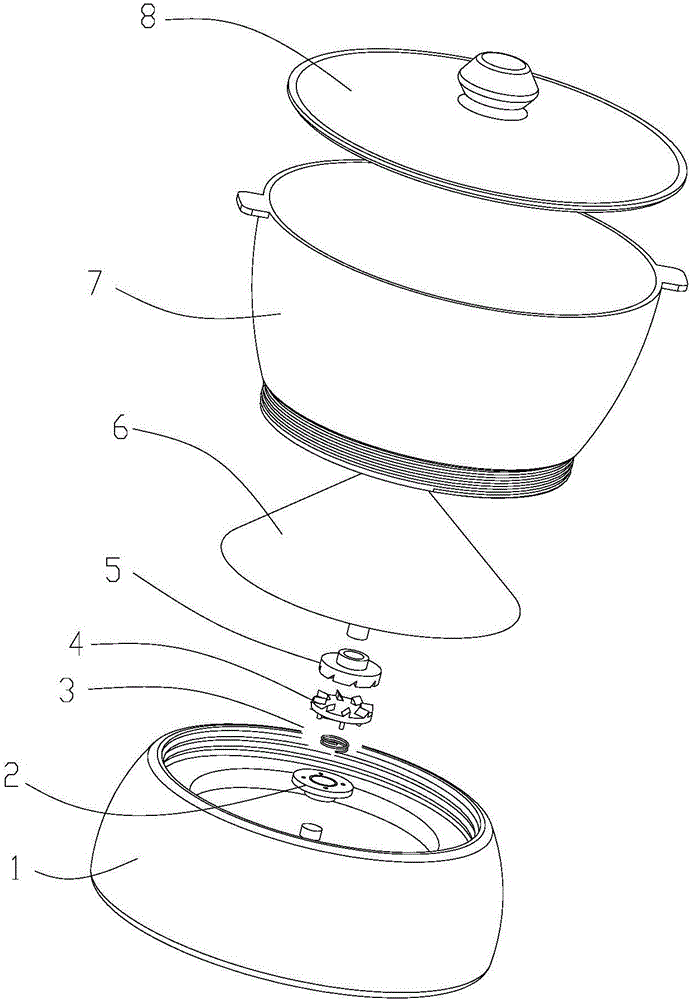

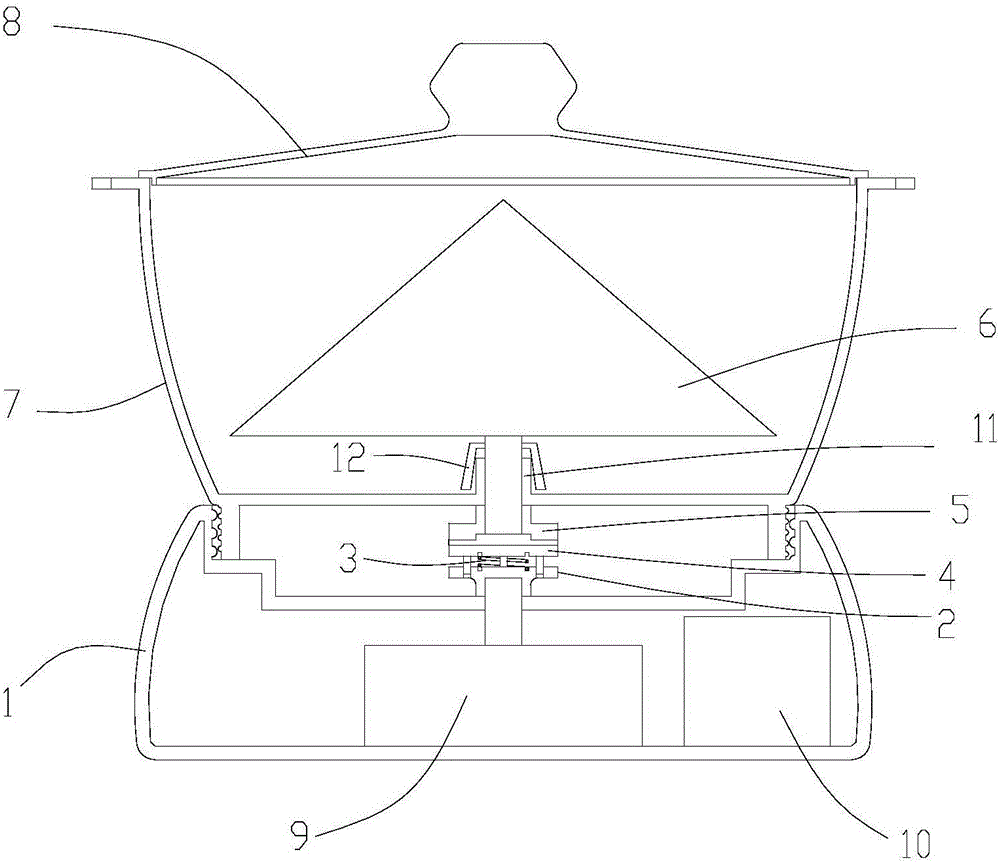

[0032] see figure 1 with figure 2 , the invention discloses a peeling machine, including a main machine, a main bowl and a cover 8;

[0033] The main engine includes a casing 1, an electrical component 10, a motor 9, and a connector; the electrical component 10 and the motor 9 are both located inside the casing 1, and the electrical component 10 is electrically connected to the motor 9; Parts are exposed on the top of the casing 1;

[0034] The main bowl is arranged on the main machine, and the main bowl includes a bowl body 7, a rotating core 6 and a clutch transmission part 5; Radially extending tough bristles; the bottom of the rotating core 6 is provided with a clutch transmission part 5 exposed at the bottom of the main bowl, and the clutch transmission part 5 cooperates with the connecting part and is detachably connected by transmission;

[0035] Cover 8 is located on the top of the main bowl.

[0036] The main engine can access electric power through the electrica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com