Ionic liquid functionalized organic polymerized monolithic column and preparation method thereof

An ionic liquid, monolithic column technology, applied in separation methods, chemical instruments and methods, solid adsorbent liquid separation, etc., to achieve the effects of fast reaction speed, simple preparation, and fast mass transfer speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

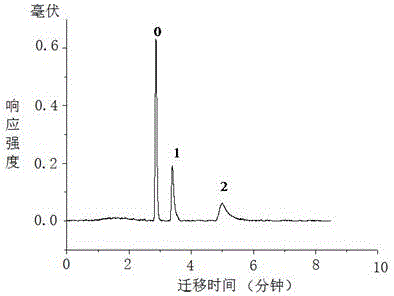

Embodiment 1

[0039] (1) Rinse the empty capillary column with 0.1 HCl solution for 15 minutes, then rinse with deionized water for 10 minutes, then rinse with 1mol / L NaOH solution for 3 hours, then rinse with deionized water for 15 minutes, then rinse with methanol for 15 minutes Minutes, blow dry with nitrogen at 50°C for later use;

[0040] (2) Inject a mixture of methanol and aminopropyltrimethoxysilane with a volume ratio of 1:1 into the empty capillary column treated in step (1), and react at 60°C for 12 hours to bond the amino group on the capillary wall. The silanized substance; washed with methanol for 15 minutes; blown dry with nitrogen at 70 ° C to obtain an aminosilanized capillary;

[0041] (3) Inject the mixture of acetonitrile and acetic anhydride with a volume ratio of 1:3 into the aminosilanized capillary in step (2), and react at room temperature for 1 hour to convert the bonded amino group on the inner wall of the capillary into acetamido; then use Rinse with acetonitril...

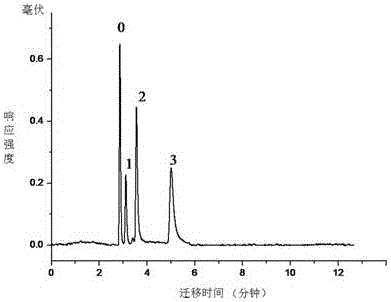

Embodiment 2

[0045] (1) Rinse the empty capillary column with 0.1 HCl solution for 15 minutes, then rinse with deionized water for 10 minutes, then rinse with 1mol / L NaOH solution for 3 hours, then rinse with deionized water for 15 minutes, then rinse with methanol for 15 minutes Minutes, blow dry with nitrogen at 50°C for later use;

[0046] (2) Inject a mixture of methanol and aminopropyltrimethoxysilane with a volume ratio of 1:1 into the empty capillary column treated in step (1), and react at 60°C for 12 hours to bond the amino group on the capillary wall. The silanized substance; washed with methanol for 15 minutes; blown dry with nitrogen at 70 ° C to obtain an aminosilanized capillary;

[0047] (3) Inject the mixture of acetonitrile and acetic anhydride with a volume ratio of 1:3 into the aminosilanized capillary in step (2), and react at room temperature for 1 hour to convert the bonded amino group on the inner wall of the capillary into acetamido; then use Rinse with acetonitril...

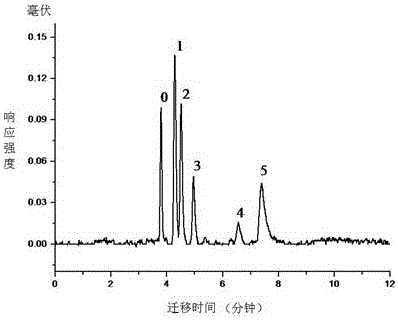

Embodiment 3

[0051] (1) Rinse the empty capillary column with 0.1 HCl solution for 15 minutes, then rinse with deionized water for 10 minutes, then rinse with 1mol / L NaOH solution for 3 hours, then rinse with deionized water for 15 minutes, then rinse with methanol for 15 minutes Minutes, blow dry with nitrogen at 50°C for later use;

[0052] (2) Inject a mixture of methanol and aminopropyltrimethoxysilane with a volume ratio of 1:1 into the empty capillary column treated in step (1), and react at 60°C for 12 hours to bond the amino group on the capillary wall. The silanized substance; washed with methanol for 15 minutes; blown dry with nitrogen at 70 ° C to obtain an aminosilanized capillary;

[0053] (3) Inject the mixture of acetonitrile and acetic anhydride with a volume ratio of 1:3 into the aminosilanized capillary in step (2), and react at room temperature for 1 hour to convert the bonded amino group on the inner wall of the capillary into acetamido; then use Rinse with acetonitril...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com