Automobile spraying device capable of realizing uniform spraying

A technology for spraying devices and automobiles, applied in the direction of spraying devices, etc., can solve problems such as easy blockage of emission holes, uneven spraying, uneven paint, etc., and achieve the effects of avoiding uneven spraying, improving filtration efficiency, and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

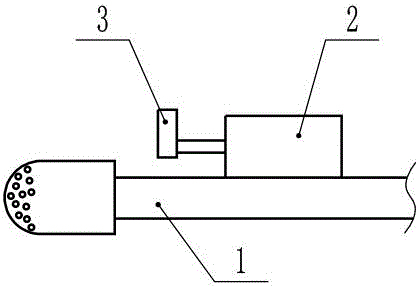

[0021] Such as figure 1 , a car spraying device with uniform spraying, the car spraying device with uniform spraying includes a six-axis articulated robot and a spray gun 1 installed at the end of the six-axis articulated robot, a vibration generator is installed on the spray gun 1, and the vibration occurs The device includes a variable frequency motor 2 installed on the spray gun 1 and an eccentric block 3 installed at the end of the output shaft of the variable frequency motor 2;

[0022] Described spray gun 1 is also connected with mixing device, and described mixing device comprises main box body and the pressure pump that is installed on the main box body, paint tank and water tank; Inlet 2 connected to the water tank, the main tank also has an output port connected to the spray gun 1 through a pressure pump;

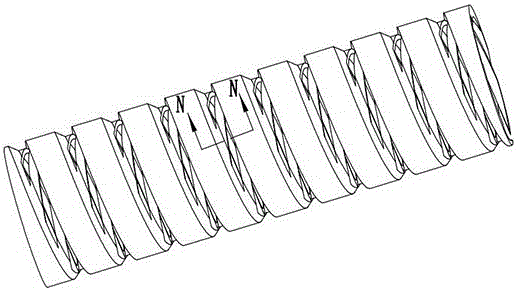

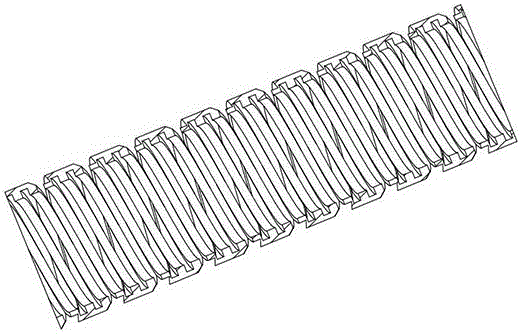

[0023] The inlet 2 is equipped wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com