Device for washing coal cinder residues at high pressure

A blanking device and high-pressure washing technology are applied in the petroleum industry, the manufacture of combustible gases, chemical instruments and methods, etc., to avoid accumulation, reduce maintenance and maintenance difficulties, and prevent environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

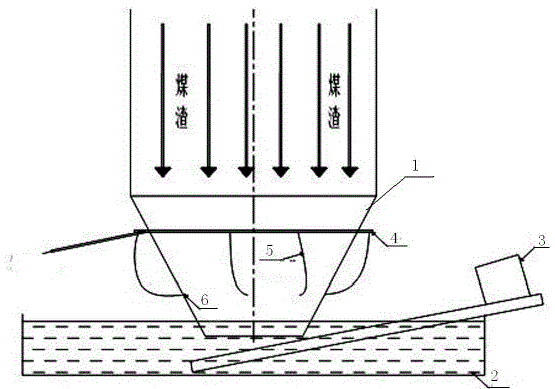

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings, but it is not intended to limit the protection scope of the present invention.

[0013] like figure 1 As shown, a high-pressure flushing cinder blanking device includes a gas furnace 1, a cinder transport motor 3 and a clean water tank 2 arranged below the gas furnace 1. Be provided with 8 rubber hoses 5. The rubber hose 5 is connected to the inner portion of the furnace wall of the gas furnace 1 and is provided with an elbow 6 . Cinder transport motor 3 is arranged on clean water tank 2 sides.

[0014] The invention uses high-pressure water to wash the coal slag blanking, avoiding the accumulation of coal slag blanking on the inclined furnace wall, thereby reducing the difficulty of maintenance and maintenance (it can be cleaned once every half a year after the modification), and preventing environmental pollution caused by coal slag blanking.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap