Centrifugal fixture

A technology of fixtures and clamping bodies, applied in the direction of chucks, etc., can solve the problems of high labor intensity, low clamping efficiency and low production efficiency of operators, and achieves time-saving and labor-saving disassembly of workpieces, low labor intensity and high production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

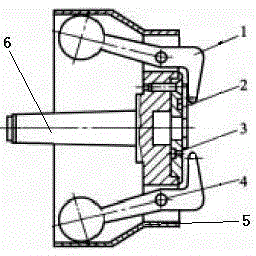

[0016] like figure 1 Shown is a schematic structural view of the centrifugal clamp of the present invention; a centrifugal clamp of the present invention includes a clamp body 5 provided with a cavity and no less than two claws 1 arranged on the clamp body 5, and the claws 1 are hinged On the clamp body 5 and one end of which extends into the cavity, and the other end extends to the end of the clamp body 5, a positioning disc 2 is provided at the end of the clamp body 5, and a positioning disc 2 is provided on the positioning disc 2 for workpiece positioning. stop pin 3.

[0017] In this embodiment, the workpiece is positioned by the end face of the positioning disc 2 and the stop pin 3, and the claw 1 pre-tightens the workpiece. After the machine is started, the claw 1 rotates with the spindle of the machine tool to generate centrifugal f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com