Automatic multi-station laser welding complete equipment

A laser welding, multi-station technology, applied in the direction of laser welding equipment, welding equipment, metal processing equipment, etc., can solve problems such as stoppage and incomplete automatic production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

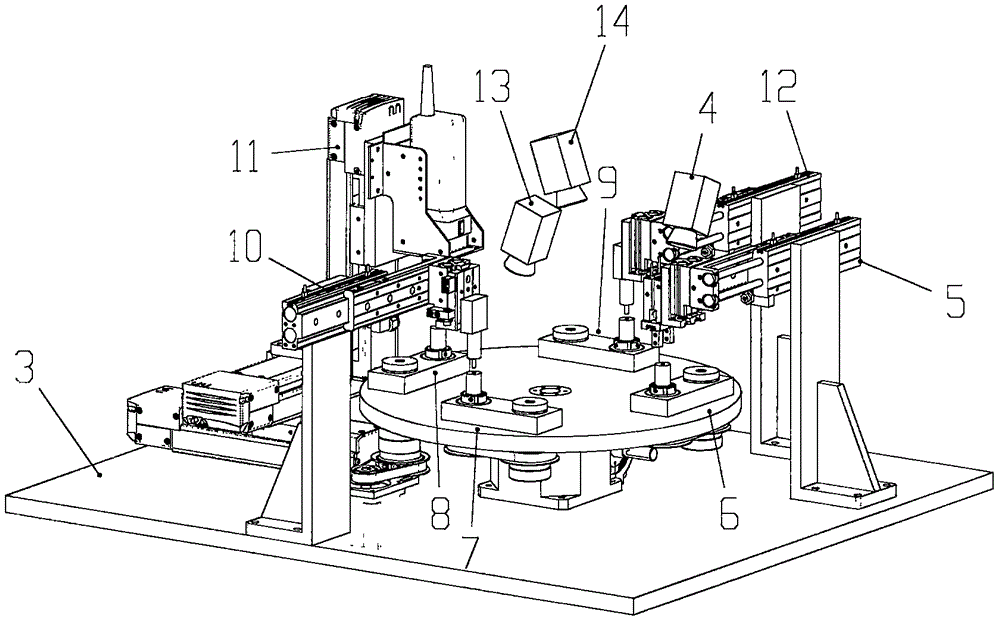

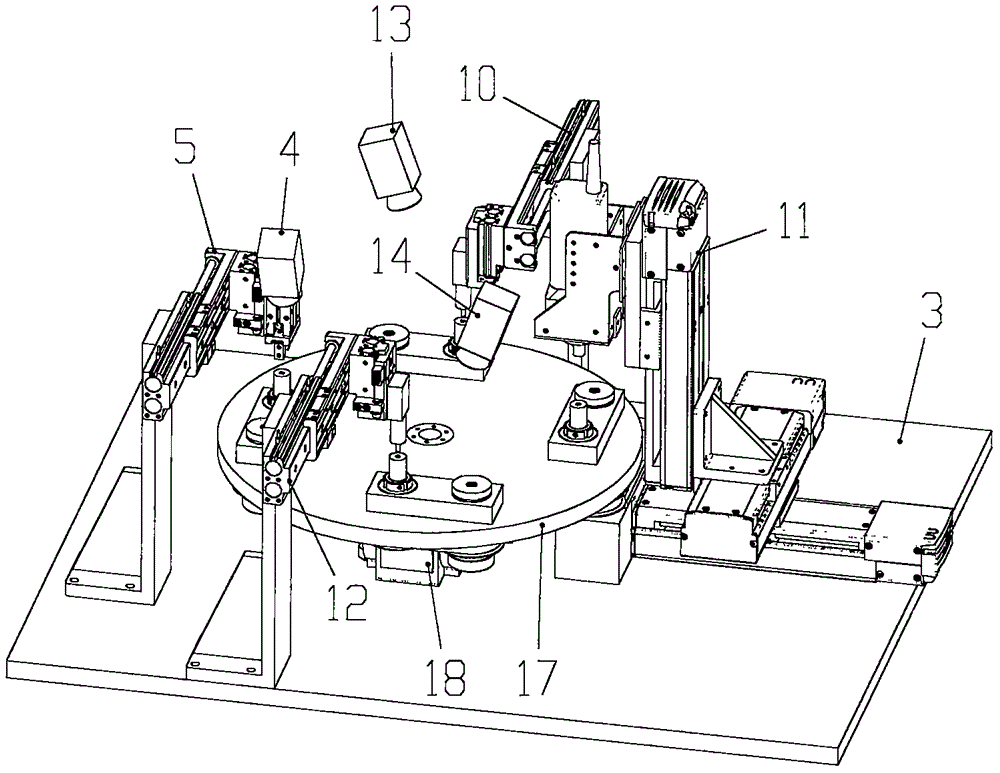

[0034] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements. As mentioned above, the present invention provides a complete set of multi-station laser welding automation equipment, the tooling is evenly distributed on the turntable, the material is loaded by the valve seat feeding manipulator and the iron sheet feeding manipulator, and the welding operation is realized by the laser welding mechanism. The unloading manipulator completes the unloading process without manual intervention in the whole process, realizing automatic operation; the position information of the product is collected by the industrial camera to prevent errors in the production process.

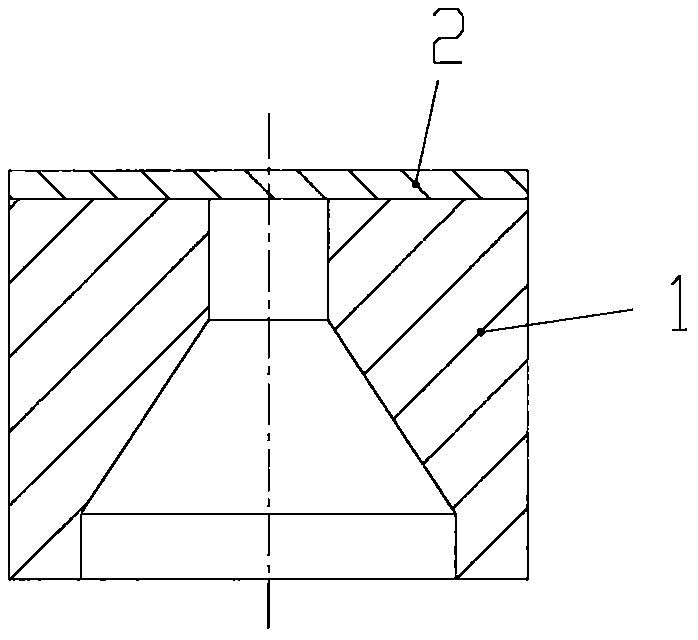

[0035] See figure 1 Firstly, the purpose to be achieved by the present invention is described, and the metallurgical connection between the valve seat 1 and the iron sheet 2 is achieved through a laser welding process.

[0036] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com