Inflatable thin film buffer cushion and machining method thereof

A processing method and cushioning technology, which are applied in the direction of preventing mechanical damage to containers, containers, cardboard items, etc., can solve the problems of increased cost, poor folding and inflation of the inner film, etc., and achieve the effect of cost saving and good inflation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

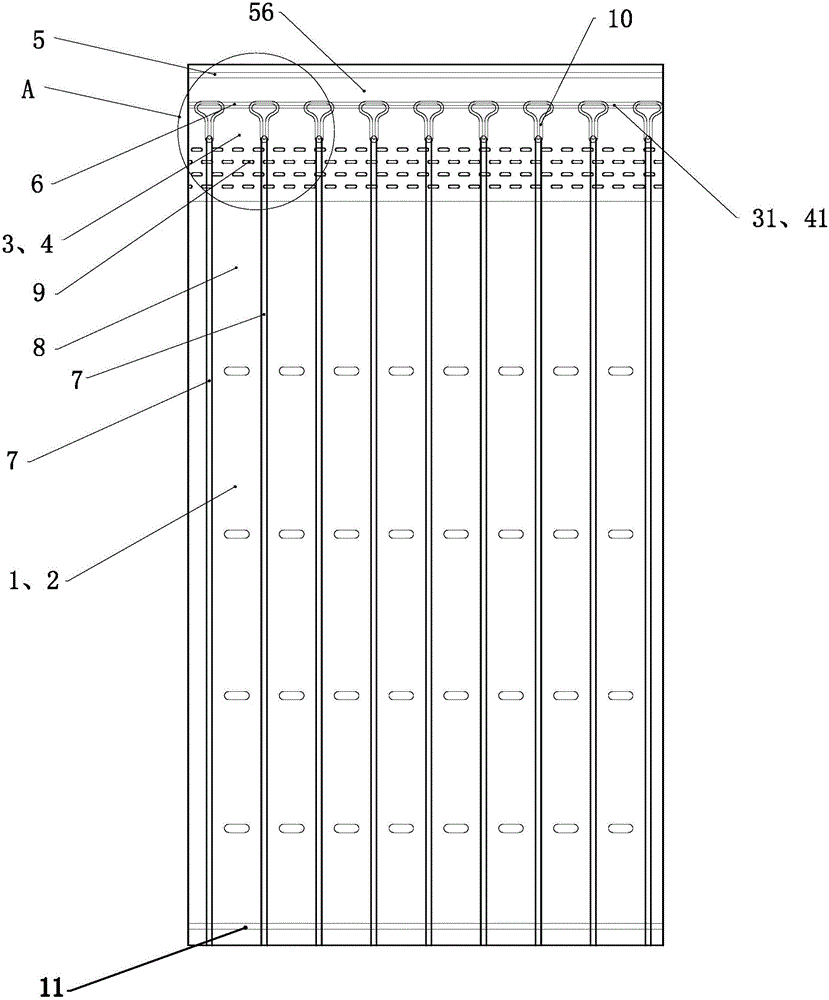

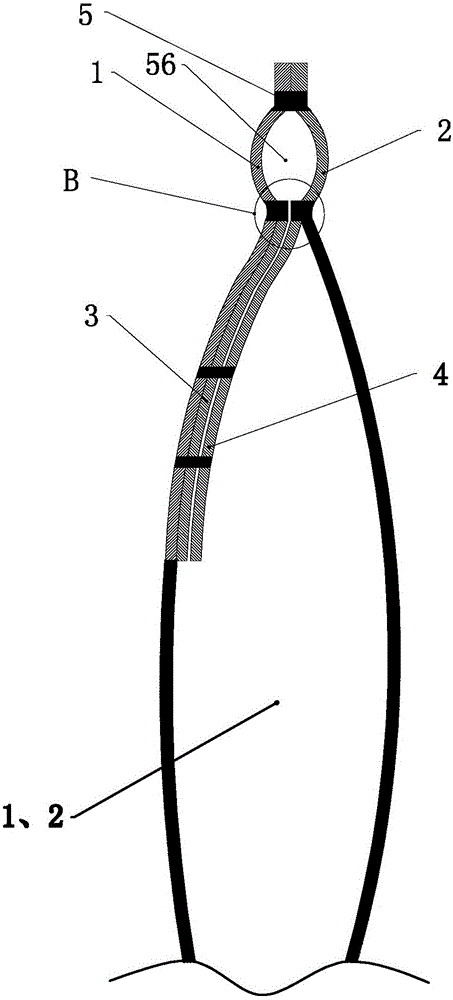

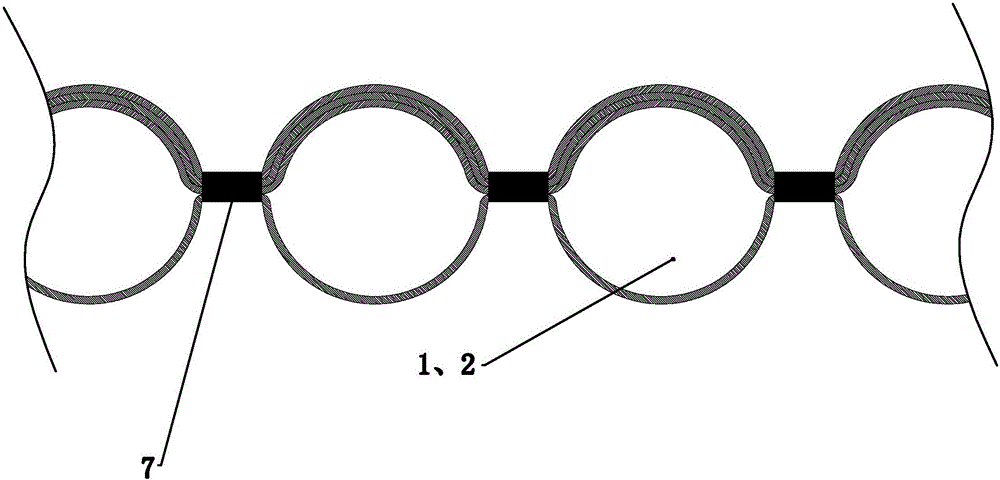

[0023] Such as figure 1 -shown in -5, a kind of inflatable film buffer pad comprises two layers of outer membranes 1,2 and two layers of inner membranes 3,4, two layers of inner membranes 3,4 are placed between the two layers of outer membranes 1,2, Two layers of inner membranes 3,4 are located on one side of the two layers of outer membranes 1,2 and the ends of the two layers of inner membranes 3,4 are located in the two layers of outer membranes 1,2, and the ends of the two layers of inner membranes 3,4 It is arranged at a certain distance from the ends of the corresponding ends of the two layers of outer films 1, 2, and the ends of the two layers of outer films 1, 2 on the side where the inner films 3, 4 are arranged are provided with a first heat-sealing line 5 and The second heat-sealing line 6, the first heat-sealing line 5 and the second heat-sealing line 6 form the main inflation channel 56 of the cushion, and the first heat-sealing line 5 makes the two outer films 1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com