Paper feeding mechanism of semi-automatic flat-pressing flat-die-cutting machine

A technology of flattening and die-cutting machine, which is applied in papermaking, object supply, paper/cardboard containers, etc. It can solve the problems of stacking and cumbersome material feeding by the lifting mechanism, and achieve a simple and controllable lifting process and convenient stacking. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

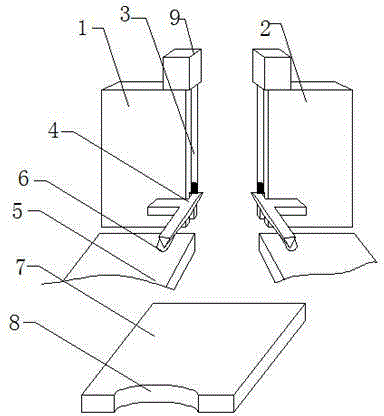

[0013] Such as figure 1 A semi-automatic flat die-cutting machine pre-feeding mechanism shown includes a left support plate 1 and a right support plate 2; a straight groove is provided on the inner side of the left support plate 1 and the right support plate 2; the inner side of the straight groove is embedded There is a hydraulic rod 3; the bottom of the hydraulic rod 3 is provided with an F-type lifting platform 4; the bite end of the F-type lifting platform 4 is fitted with the straight groove; the front side of the bite end of the F-type lifting platform 4 is arranged There is a linear guide rail 5; the front side of the linear guide rail 5 is provided with an embedding groove 6 fitted with the end of the straight beam of the F-type lifting platform 4; the linear guide rail 5 is provided with a carton stacking plate 7.

[0014] Wherein, the rear side of the carton stacking plate 7 is provided with a force application port 8; the hydraulic rod 3 is installed in cooperation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com