Circulation type electroplating liquid filtering device

A technology of filtering device and electroplating solution, which is applied in the electrolysis process, electrolysis components, cells, etc., can solve the problems of adverse effects on staff and the surrounding environment, incomplete filtration, affecting work efficiency, etc., to achieve self-cleaning effect and reduce replacement. The number of times, the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

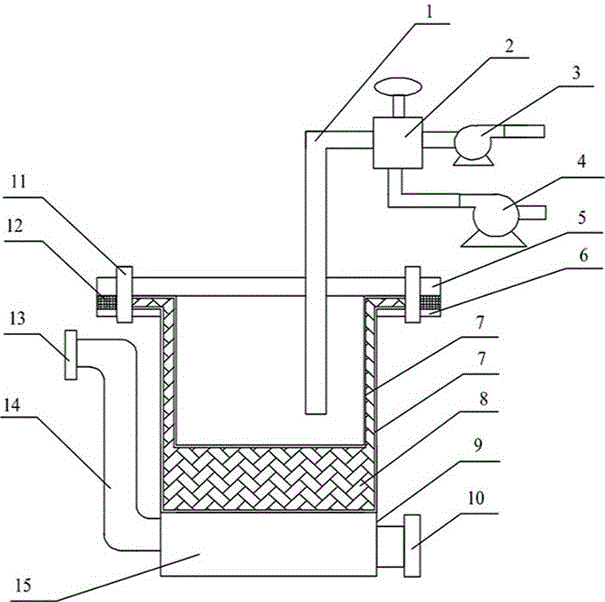

[0030] Such as figure 1 As shown, the present invention is a circulating plating solution filtering device, a circulating plating solution filtering device, comprising a cylinder 9, a filter bag 8, a filter frame 7 and a top cover 5, and the upper port of the cylinder 9 is provided with Ring support mechanism 6. The filter frame 7, filter bag 8, filter frame 7 and top cover 5 are placed on the top of the ring support mechanism 6 from bottom to top, and the five are pressed and fixed by the fixing part 11. The bottom surface in the cylinder 9 and the filter frame 7 The cavity between them is the concentrating chamber 15, and the side of the concentrating chamber 15 is provided with a liquid inlet pipe 14 and a feed liquid outlet 10, and the liquid inlet pipe 14 is vertically arranged to be perpendicular to the side wall of the cylinder body 9, so that the inlet end of the liquid medicine reaches at least the cylinder. half of the height of body 9. It also includes a conduit 1...

Embodiment 2

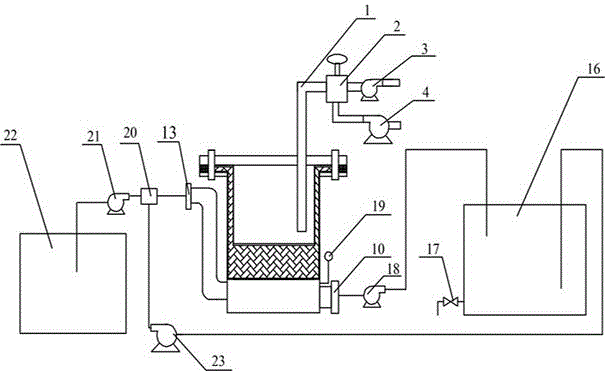

[0032] Such as figure 2As shown, the present invention is a circulating plating solution filtering device, which also includes a liquid storage tank 16 and a plating solution tank 22 . The liquid storage tank 22 is connected to the feed liquid outlet 10 through a pipeline, and an outlet pump 18 is provided on the connecting pipeline between the liquid storage tank 22 and the feed liquid outlet 10 . The plating solution tank 22 is also provided with a pipeline connected to the liquid medicine inlet 13, the pipeline is provided with a circulation pump 23, the plating solution tank 22 is connected with the medicine solution inlet 13 through a pipeline, and the pipeline is provided with a liquid inlet pump 21. A pressure display device 19 may be provided on the concentrating chamber 9 .

[0033] It can also preferably include a premixed tank 20, the input port of the premixed tank 20 is connected to the output port of the circulating pump 23 and the output port of the liquid inl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com