Road engineering chute

A technology of road engineering and rapid trough, which is applied in the field of rapid trough, can solve the problems of easy deposition of silt at the bottom of the tank and difficulty in opening the top cover, etc., and achieve the effect of simple structure, increased swing action and flexible swing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

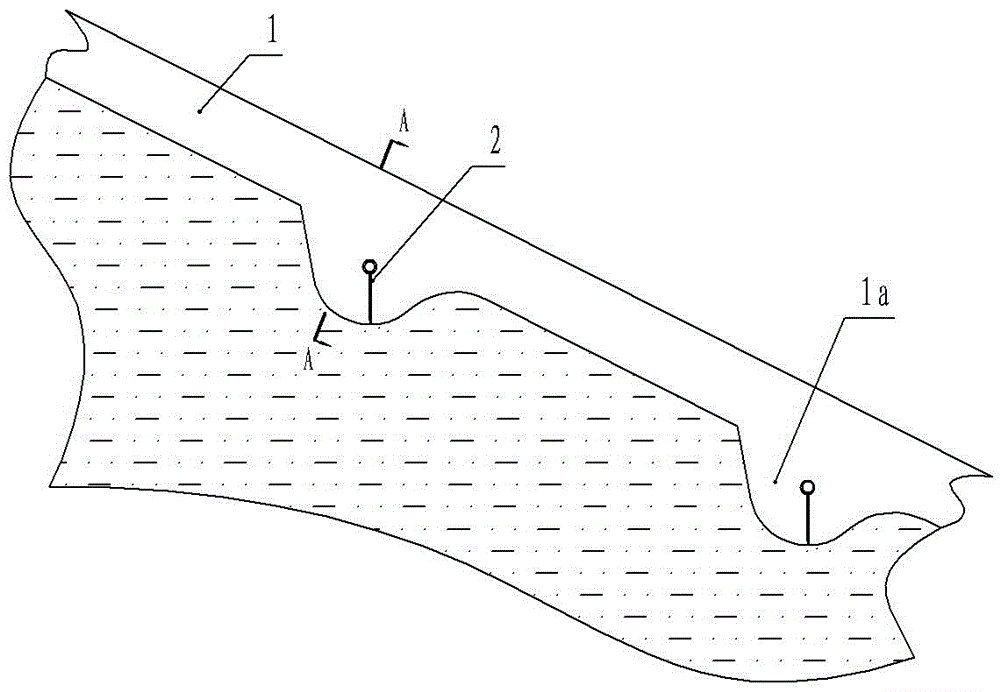

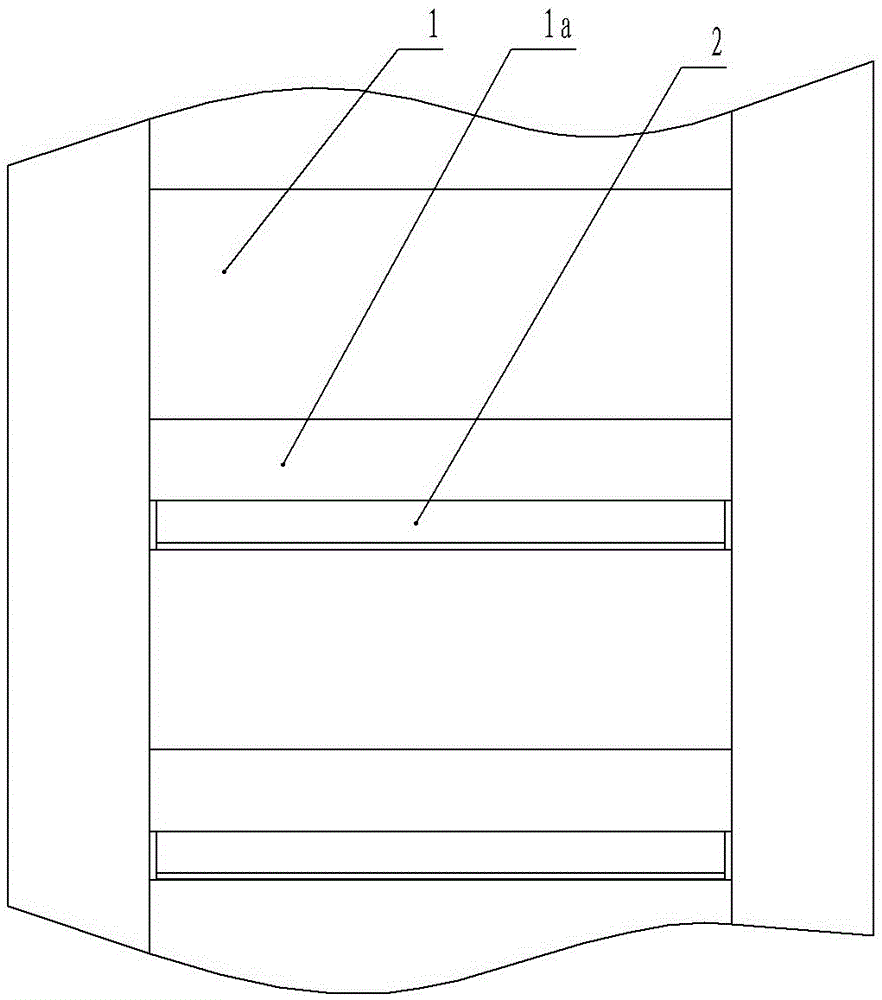

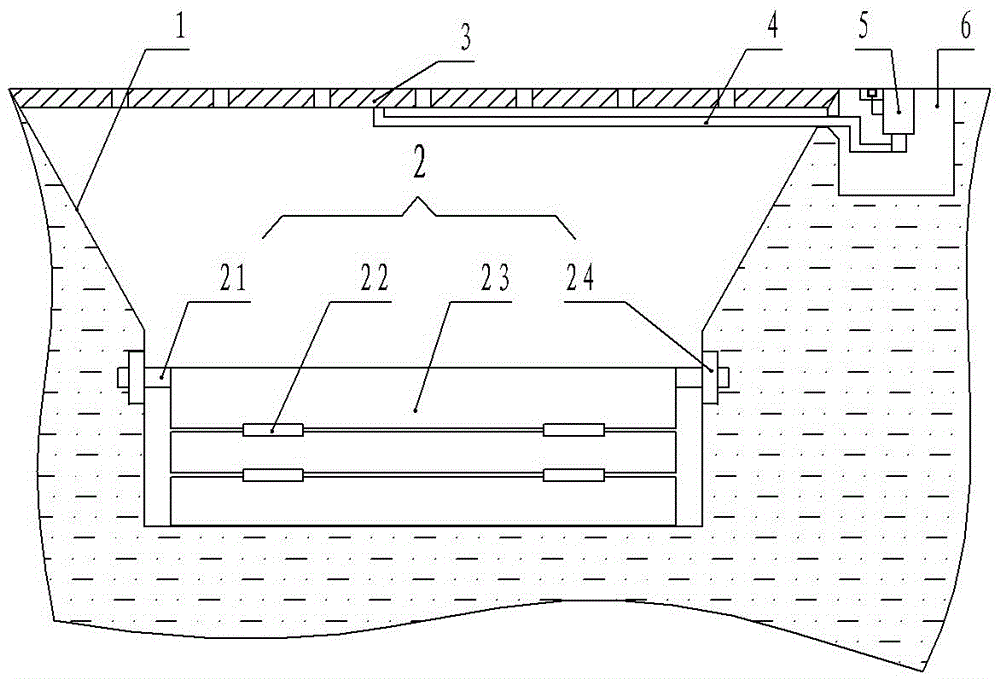

[0014] figure 1 , figure 2 , image 3 The road engineering rapid trough shown includes a tank body 1 and a top cover 3 arranged on the tank body. The bottom of the tank body 1 is provided with a plurality of energy dissipation pools 1a arranged in sequence along the water flow direction, and each energy dissipation pool 1a The inner wall surface of each energy dissipating pool 1a is an arc surface inclined forward, and a rotating shaft 21 is connected between the two side walls of each energy dissipation pool 1a. The rotating shaft 21 is equipped with a movable plate 2 transverse to the direction of water flow. The movable plate 2 is formed from the upper A plurality of sub-pieces 23 that are hinged to each other through hinges 22 constitute downwards. The upper end of the top sub-piece 23 is provided with a reel. On the side wall of the energy diss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com