A monitoring method for the displacement efficiency of cementing annulus in simulated shale gas horizontal wells

A technology for displacement efficiency and horizontal wells, applied in construction and other fields, can solve problems such as lack of convincing power, large experimental errors, and flow field interference, and achieve the effects of improving cementing quality, strong field applicability, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Further illustrate the present invention according to accompanying drawing and embodiment below.

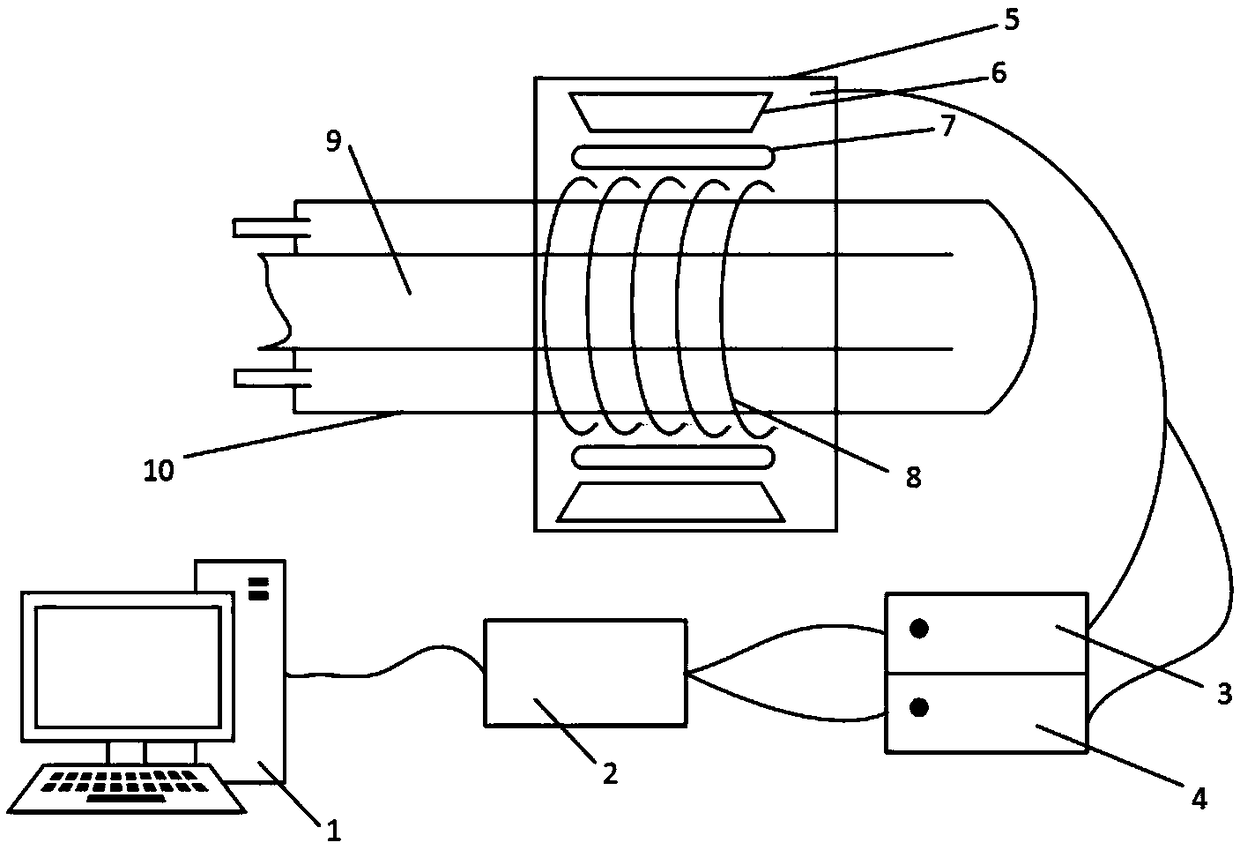

[0027] see figure 1 .

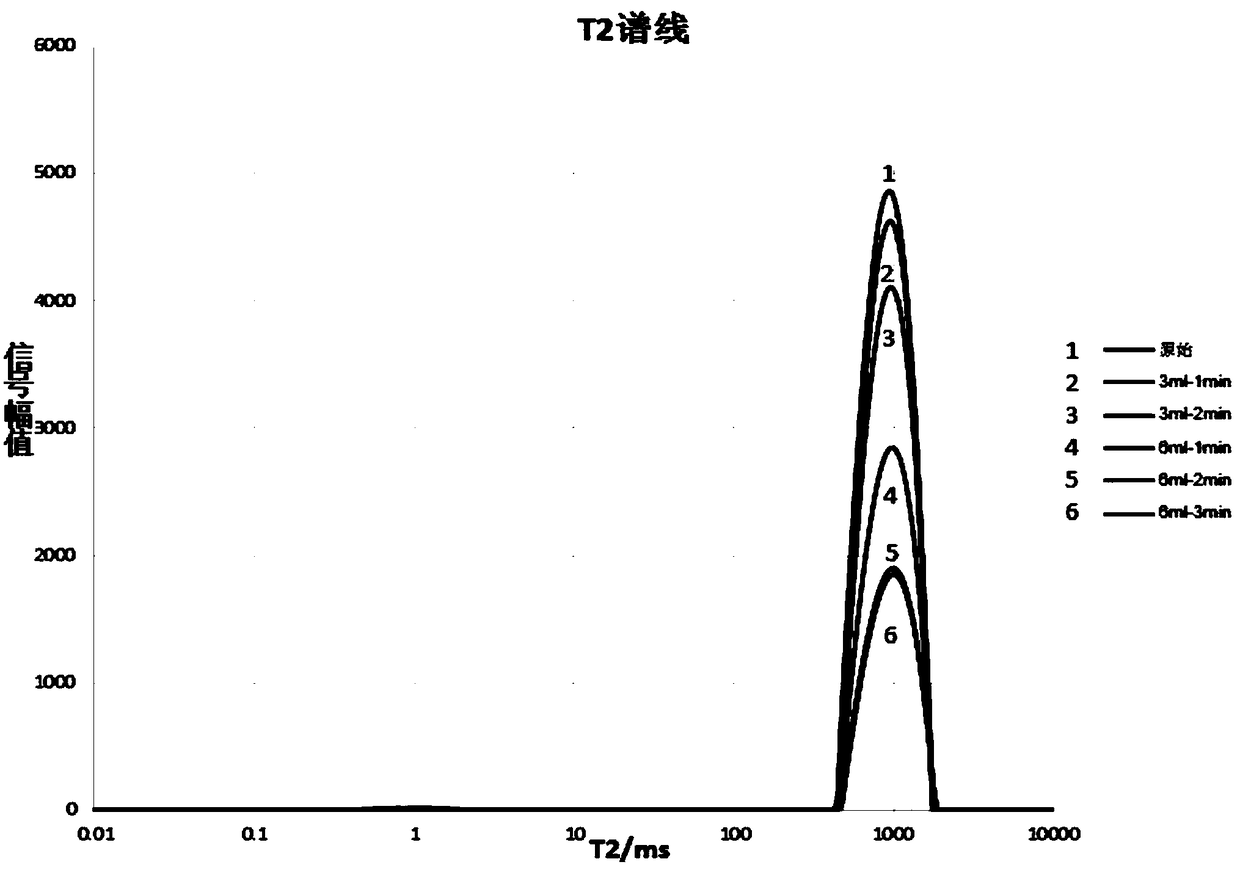

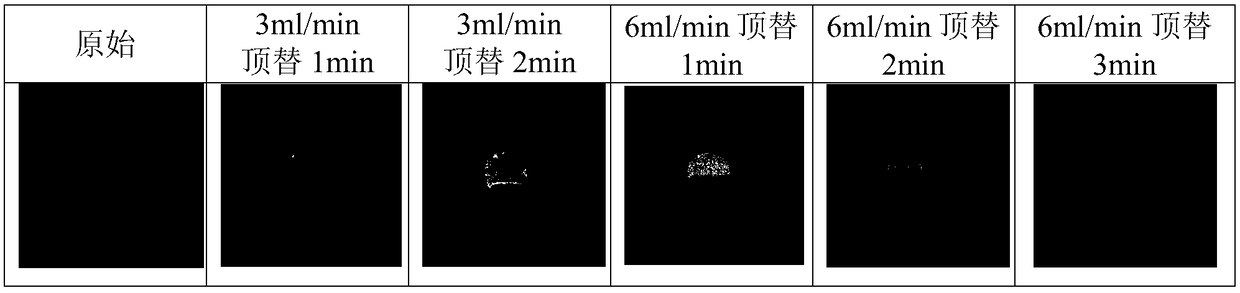

[0028] A monitoring method for simulating the displacement efficiency of cementing annulus in a shale gas horizontal well, the method is realized by using a low-field nuclear magnetic resonance imager, and the low-field nuclear magnetic resonance imager is composed of a computer 1, a spectrometer system 2, and a radio frequency unit 3 , a gradient unit 4, and a magnetic box 5. The magnetic box 5 is connected to the spectrometer system 2 and the computer 1 in turn through the radio frequency unit 3 and the gradient unit 4. There are magnets 6, gradient coils 7, and radio frequency coils 8 in the magnetic box. The magnet has two magnetic poles, and the gradient coil is also composed of two pole plates. An annular measuring pipe section simulating a horizontal wellbore is placed in the radio frequency coil, and the annular measuring pipe section inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com