Rotary drawing wire

A technology of wire drawing and wire core, which is applied in the direction of engine control, machine/engine, mechanical equipment, etc., can solve the problems of occupying space, easy to rotate, twist and deform, and lose the fulcrum of wire drawing, so as to prolong the service life, increase the torsional performance, and ensure The effect of long-term use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The convoluted wire drawing of the present invention will be further described below in conjunction with the embodiments of the accompanying drawings.

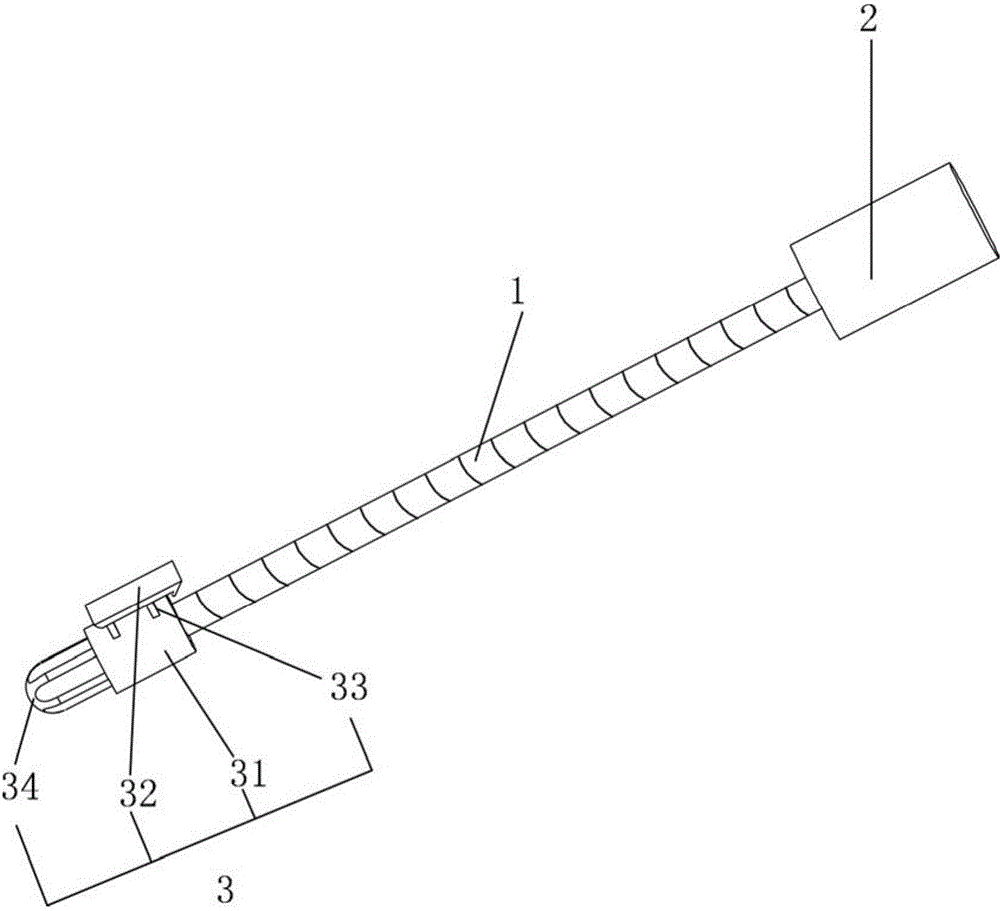

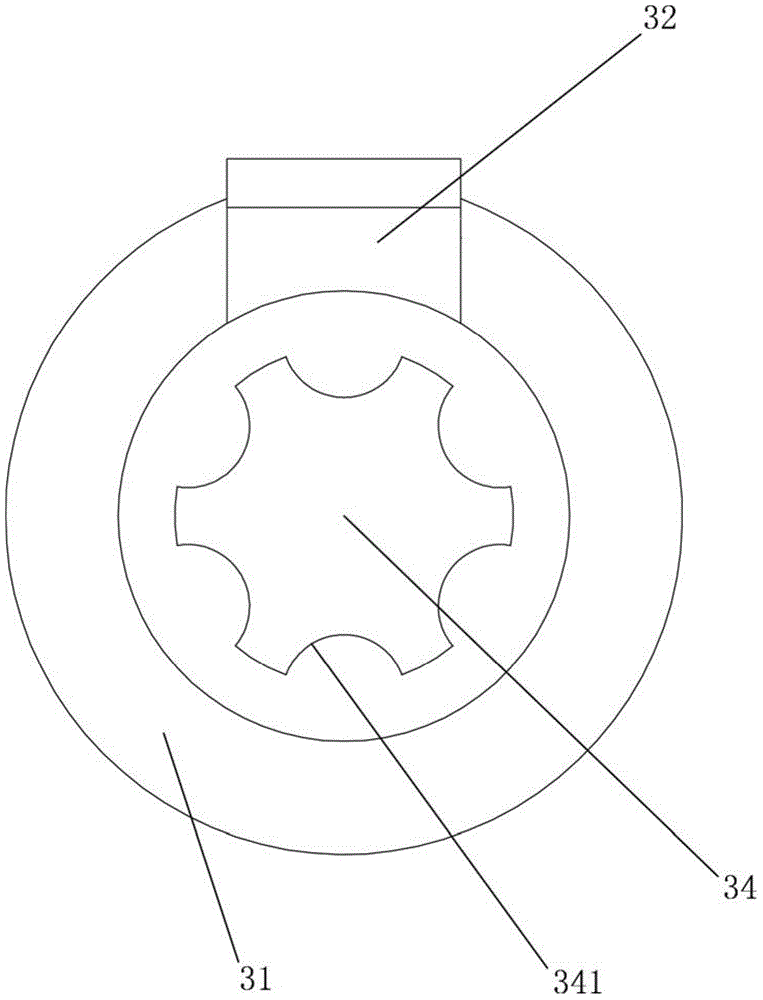

[0018] Such as figure 1 , figure 2 As shown, a convoluted wire drawing includes a front end 3, a wire core 1 and a rear end 2, the front end 3 and the rear end 2 are respectively arranged at the two ends of the wire core 1, and the wire core 1 has a number of metal wires intertwined Formed, the front end head 3 is provided with a hook 32 .

[0019] By adopting the above-mentioned scheme, the wire core 1 is wound with several metal wires. Since the metal wires are coiled with each other, the torsional modulus of the wire core 1 can be increased, which can increase the resistance of the wire core 1 of the spiral drawing. Torque, prolong the service life of wire core 1. And a hook 32 is set on the front end head 3, so that the back end head 2 can be connected with the equipment during the use of the swivel wire drawing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com