Flange of radiating fixed rotating shaft

A technology for fixing the rotating shaft and the fixed disc, which is applied to transmission parts, belts/chains/gears, mechanical equipment, etc., which can solve problems such as unfavorable maintenance, reduced service life, poor corrosion resistance, etc., to facilitate production and maintenance, and increase service life , good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

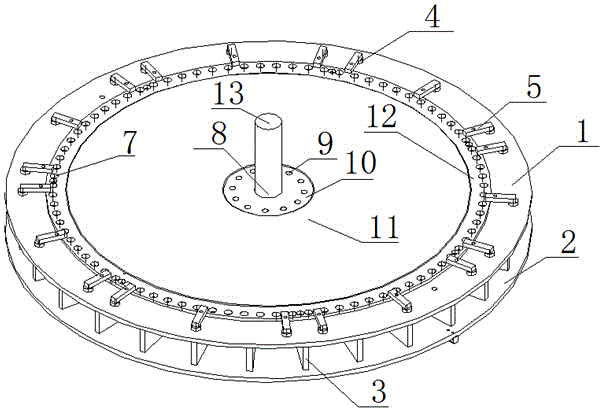

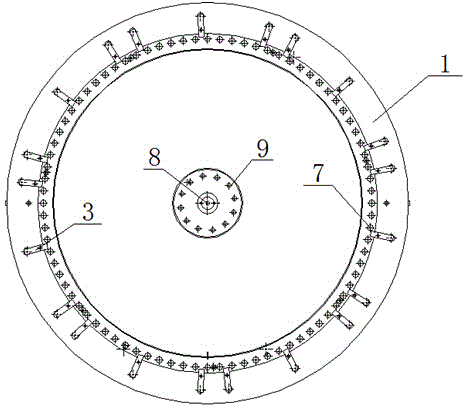

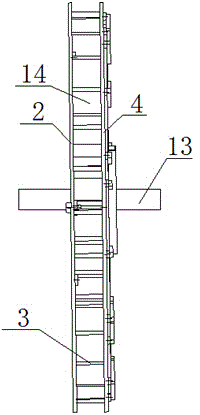

[0017] Specific implementation method: first, a fixed shaft disk 11 is arranged in the middle of the fixed disk base 2, and an inner flange ring 10, a shaft hole 8 and a through hole 9 are arranged in the fixed turntable 11, and the inner flange ring 10 is evenly distributed around the circle. There are many through holes 9 and shaft holes 9 are arranged in the middle. The shaft holes 8 match the shaft 13. There are many welding support blocks 3 between the fixed disk base 2 and the docking disk 1. When the shaft is rotating , the vent 14 is used for heat dissipation, the shaft hole 8 is matched with the shaft 13, and there is no shaking during rotation, which increases the service life of the flange. The inner side of the docking disc 1 is provided with a flange ring 12, The flange ring 12 is evenly provided with many screw holes 7 around the circumference, the surface of the butt joint 1 is welded with many gaskets 4, and the surface of the gasket 4 is welded with a welding f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com