I-beam steel-based manual leveling device for power distribution cabinet

A technology of leveling device and I-beam, applied in the direction of substation/distribution device casing, etc., can solve the problems of laborious, time-consuming, and many adjustment times, and achieve the effect of saving manpower and material resources, simplifying structure, and simplifying the leveling process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below with reference to the accompanying drawings and examples.

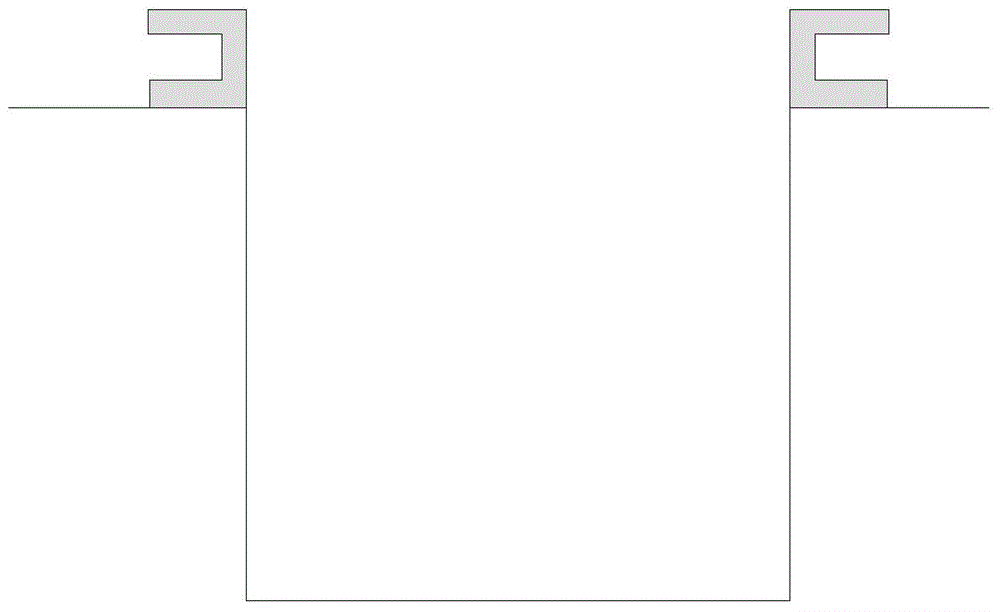

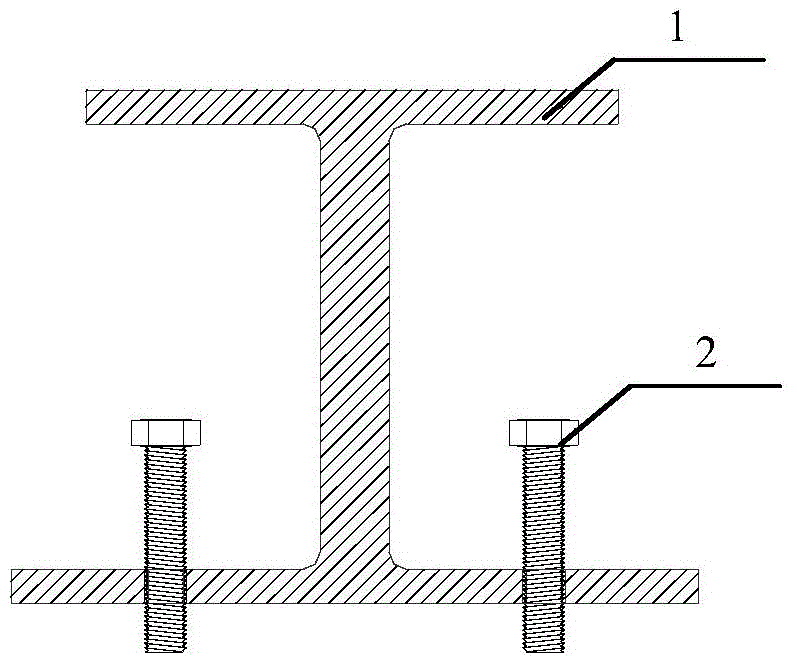

[0014] The present invention provides a manual leveling device for a power distribution cabinet based on I-shaped steel. The leveling device includes two I-shaped steels 1 . First dig a deep pit on the ground for wiring as a wiring trough; set two I-shaped steels on both sides of the opening of the wiring trough. Four adjustment bolts 2 are installed on a bottom surface of every I-shaped steel, thereby forming a stable supporting surface. The four adjusting bolts are distributed in pairs at both ends of the I-shaped steel, and the connection line of the four adjusting bolts forms a rectangle; the two adjusting bolts at the same end are located on both sides of the I-shaped steel middle beam.

[0015] When leveling is required, left and right leveling and front and rear tilting can be realized by adjusting the four adjusting bolts. With the use of a level...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com