RHU shell with thermal expansion matching performance

A technology of matching performance and thermal expansion, applied in the direction of cabinet/cabinet/drawer parts, etc., can solve problems such as damage and large stress, and achieve the effects of stable performance, release of thermal stress, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

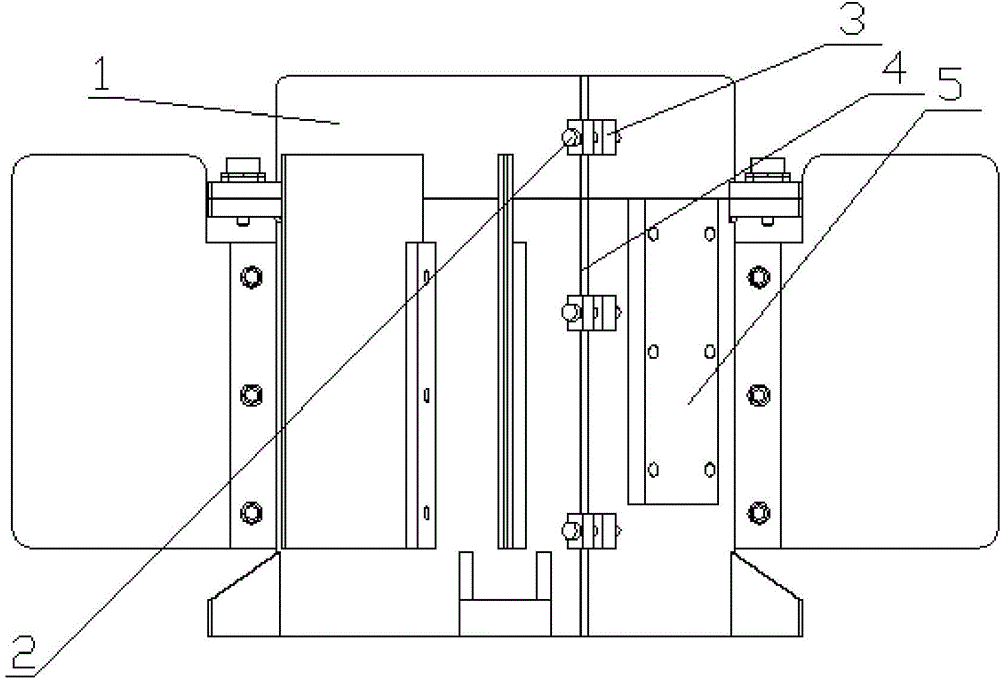

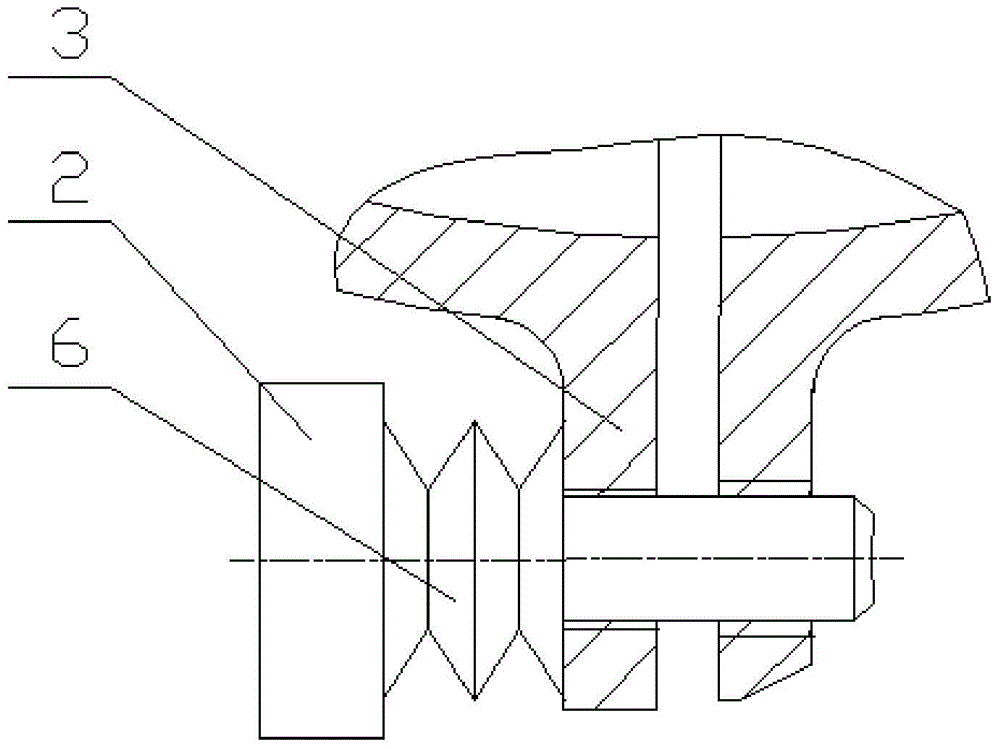

[0024] A RHU shell with thermal expansion matching performance is provided with a slit on the side of the RHU shell, and the RHU shell releases stress through the slit when heated and expanded; the width of the slit is greater than the deformation of the RHU shell at the highest temperature. There are three lugs at the position of the gap, which are fastened with screws, and a butterfly spring is added between the screws and the lugs, and the contraction of the gap is realized through the deformation of the butterfly spring.

[0025] The concrete structure and implementation process of this embodiment are as follows:

[0026] A RHU shell with thermal expansion matching performance. According to the lunar ambient temperature and the output power of the isotope nuclear source, the maximum temperature that the RHU shell may reach during the lunar day is calculated.

[0027] According to the nominal size of the RHU shell measured at normal temperature (20°C), the maximum temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com