Off-line tracking method of curved seam for arc welding robot welding

A robot welding and robot technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., to achieve continuous and stable welding, improve measurement accuracy, and simple solutions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] It should be noted that the embodiments of the present invention and the features in the embodiments can be combined with each other if there is no conflict.

[0024] Hereinafter, the present invention will be described in detail in conjunction with embodiments:

[0025] The process of implementing the present invention:

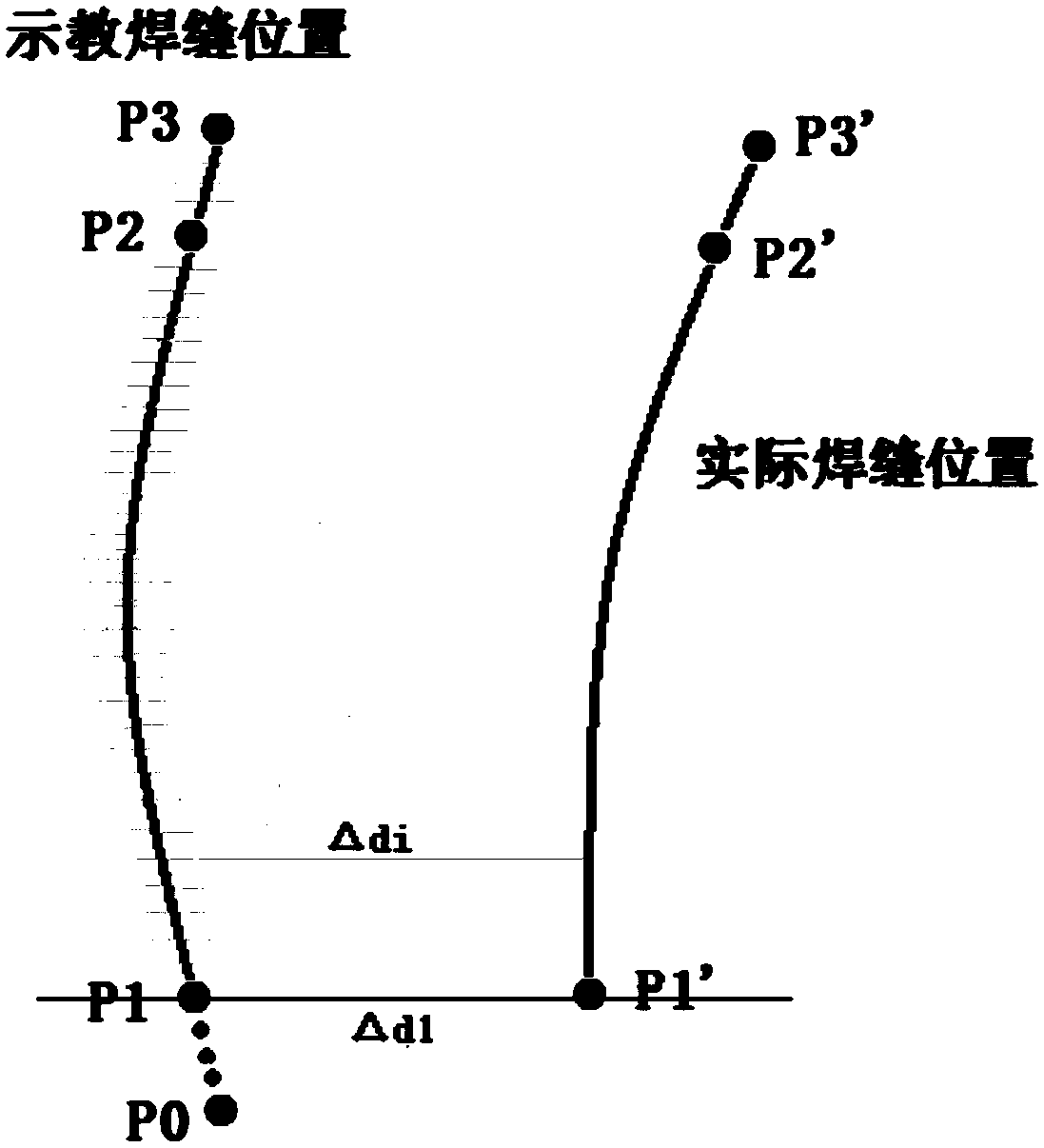

[0026] Such as figure 1 As shown, it shows the teaching weld position and the actual weld position.

[0027] P1 is the starting point of the teaching weld, and P1' is the starting point of the actual weld.

[0028] P3 is the end point of the teaching weld, and P3' is the end point of the actual weld.

[0029] P0 is the position point separated from the starting point of the welding seam by the leading distance between the measuring sensor and the robot, which is the point P1 extended in the opposite direction according to the curvature, and the linear distance from the P1 point is equal to the leading distance.

[0030] P2 is the position point that is linearly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com