Apparatus for welding seals of medical sterilized cotton swabs and machine for filling liquid

A technology of welding device and sterilized cotton, which is applied in the field of medical sterilized cotton swab sealing and welding device, can solve the problems of staying in manual work, and achieve the effects of improving production efficiency, ensuring sealing quality, and improving production technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

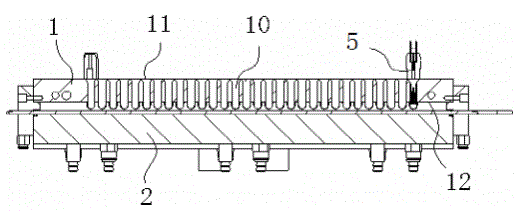

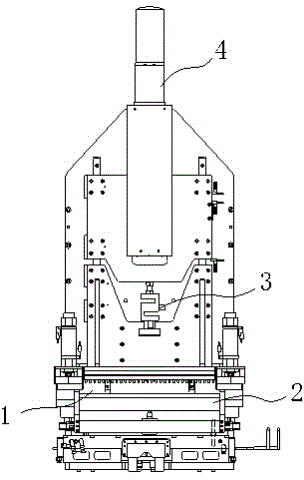

[0021] See figure 1 , shown in the figure is a medical sterilized cotton swab 5 sealing welding device, which is mainly composed of a first welding mold body 1 and a second welding mold body 2.

[0022] The first welding mold body 1 has a first surface 11 and a second surface 12 opposite to the first surface 11, and at least one socket for a cotton swab 5 is formed on the first welding mold body 1. The accommodating chamber 10 , and the accommodating chamber 10 has an open end and a closed end, the open end is disposed on the first surface 11 , and the closed end is disposed on the second surface 12 . Further, the closed end of the accommodating cavity 10 protrudes from the second surface 12 of the first welding mold body 1 . In this embodiment, the number of the accommodating cavities 10 is 60.

[0023] The second welding pattern 2 is adjacent to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com