Damping compensator

A compensator and bellows technology, applied in the field of shock absorbing compensators, can solve the problems that the effect of shock absorption and noise reduction is not as good as that of rubber compensators, the performance of high pressure resistance is poor, and it is not easy to promote, so as to achieve good shock absorption effect and enhance shock absorption effect. , cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

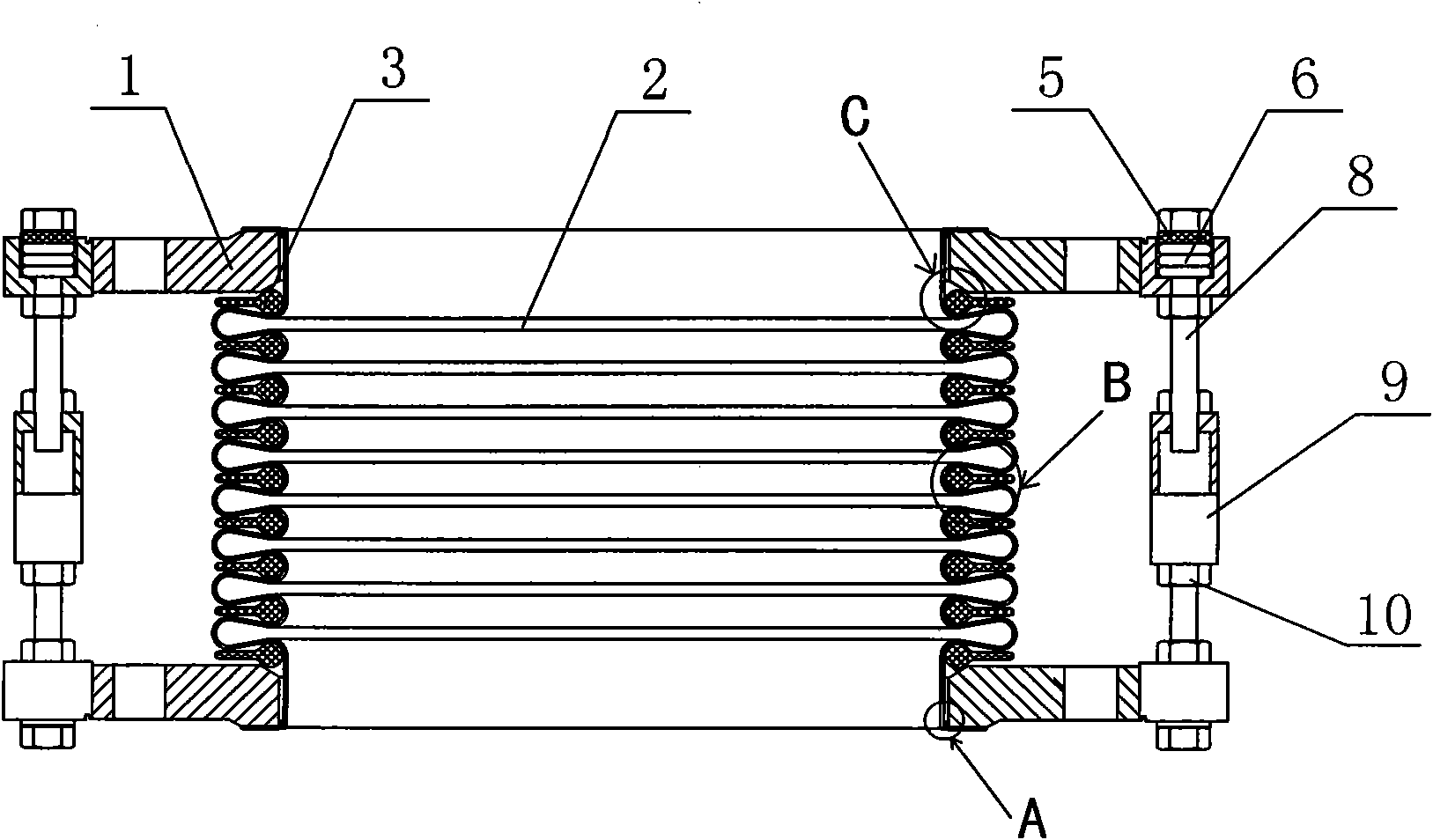

[0018] refer to Figure 1 to Figure 4 As shown, in this embodiment, a shock absorber compensator includes an "S"-shaped bellows 2, the two ends of the bellows 2 are connected with a connecting flange 1, and the connecting flange 1 is hollowed out. The structure, through finite element analysis, strengthens the main force-bearing points and thins the non-stress points, which can not only meet the strength requirements of the product, but also reduce weight and save costs.

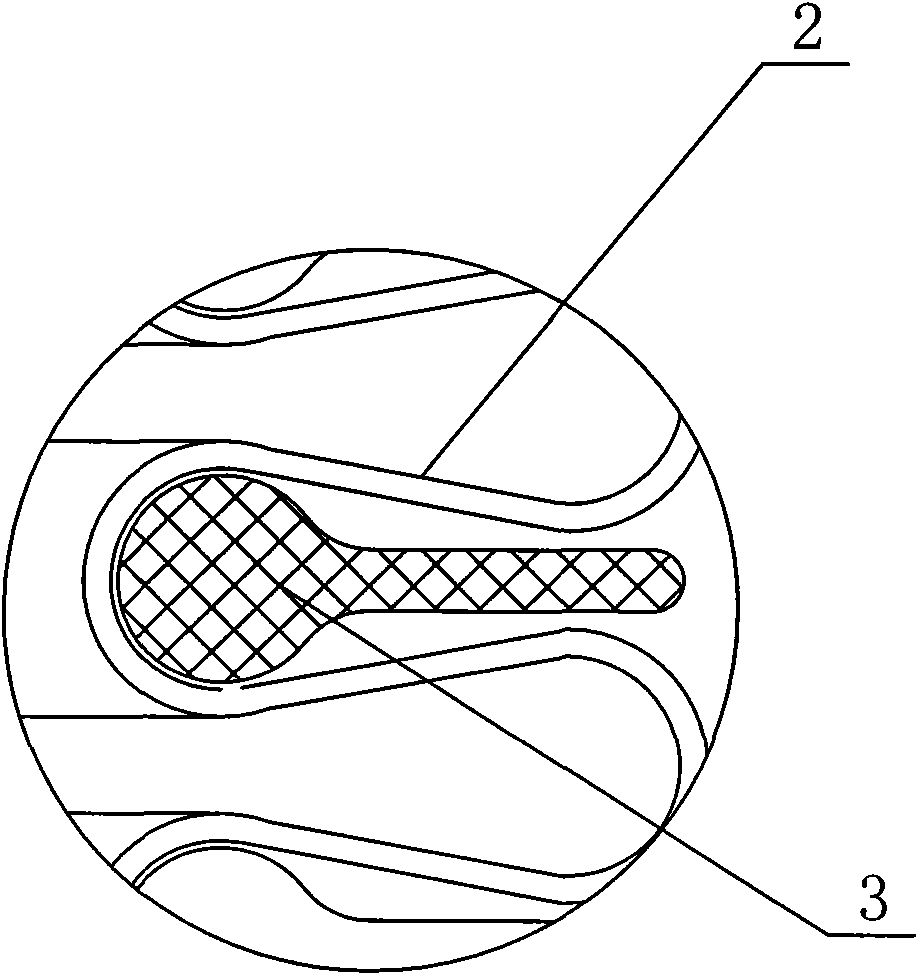

[0019] The troughs of the bellows 2 are all equipped with rubber rings 3 made of high-quality rubber. The cross-section of the rubber rings 3 is tadpole-shaped, and the flexibility of the rubber is used to absorb the vibration energy of the system. The rubber rings 3 meet the requirements of shock absorption. At the same time, it can prevent the corrugated pipe 2 from being squeezed and deformed due to excessive deformation.

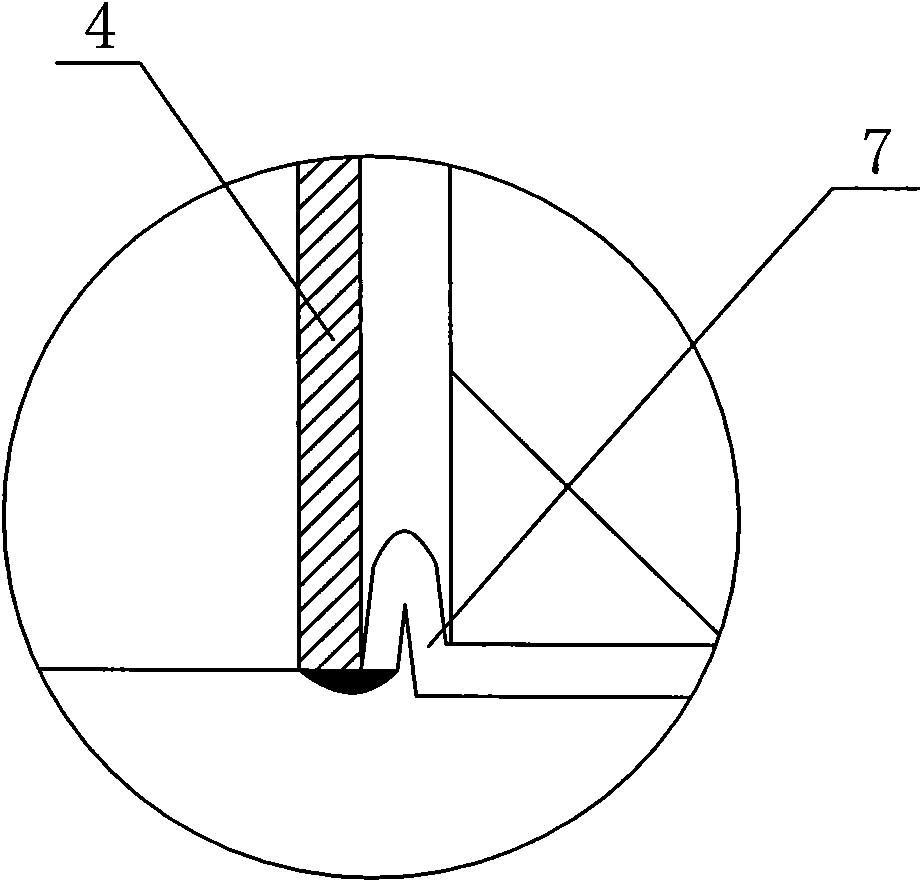

[0020] The connecting flange 1 is looped on the straight section 4 of the bellows...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com