High-strength low-hydration-heat well cementation cement and preparation method thereof

A low hydration heat, cementing technology, which is applied in chemical instruments and methods, cement production, drilling composition, etc. It is difficult to develop and achieve satisfactory results, etc., to achieve the effect of improving the cement hydration process, reducing the peak hydration heat release and the total amount of heat release, and improving the arrangement and folding method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] As a preferred embodiment of the present invention, in this embodiment, in each high-strength low-heat-of-hydration cementing cement, 73 parts by weight of low-heat-of-hydration cementitious materials were weighed, and the low-heat-of-hydration cement used was Coagulation material is made of C 2 The highly active Portland cement clinker, zircon and baddeleyite with S content greater than 40% are fully mixed and ground according to the set ratio, and the mineral content is: 30%~45% C 2 S, 30%~45% C 3 S, 0.2%~1.5% C 3 A. 10%~16% of C 4 AF, 1%~10% ZrSiO 4 ; Specific surface area ≥ 350m 2 / kg, SO 3 ≤3%. In parts by weight, take 15 parts of low-hydration active materials, the low-hydration active materials are selected from one or more mixtures of metal slag and ultrafine fly ash, and the metal slag is steel slag, manganese slag and copper slag. One or a combination of several, the physical properties of the low-hydration active material meet: specific surface area ≥ ...

Embodiment 2

[0055] As another preferred embodiment of the present invention, in this embodiment, the high-strength and low-heat of hydration cementing materials used in each high-strength and low-heat of hydration cement are made of low-heat of hydration Portland cement clinker, zirconium The quartzite and baddeleyite are weighed according to the ratio of 80:12.5:5, and then fully mixed and ground. The mineral content is: 30%~45% C 2 S, 30%~45% C 3 S, 0.2%~1.5% C 3 A. 10%~16% of C 4 AF, 1%~10% ZrSiO 4 ; Specific surface area ≥ 350m 2 / kg, SO 3 ≤3%; the low-hydration active material is a mixture of one or more of metal slag and ultra-fine fly ash, and the physical properties of the low-hydration active material meet: specific surface area ≥ 500m 2 / kg, SO 3 ≤3%. Metal slag is one or a mixture of steel slag, manganese slag and copper slag. The reinforcing agent is composed of a certain amount of calcium sulfate whiskers, ultrafine ceramics and graphene oxide powder, with a specific ...

Embodiment 3

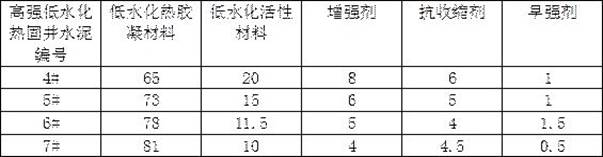

[0063] As another preferred embodiment of the present invention, the high-strength and low-heat-of-hydration cement is prepared in this embodiment, which contains the following components in parts by weight:

[0064] Weigh two parts of high-strength and low-heat of hydration cementing cement in sequence, by mass percentage, 73% of finely ground high-strength and low-heat of hydration cementitious material, 15% of low-hydration active material, 6% of reinforcing agent, and anti-shrinkage agent 5%, early strength agent 1%; the above-mentioned five components are weighed in turn and mixed uniformly to obtain high-strength, low-density, low-heat-of-hydration cement.

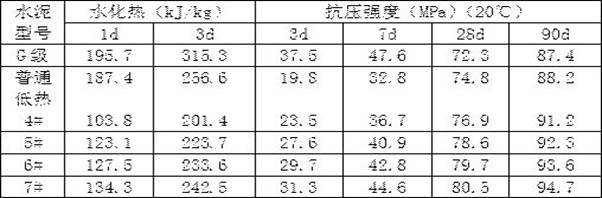

[0065] The high-strength, low-density and low-hydration heat cementing cement obtained according to the above configuration is configured with conventional density cementing cement slurry and the density is 1.50g / cm 3 The low-density cementing slurry; the water-cement ratio of the conventional density cement slurry i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com