Scaffold clamp

A scaffolding and fixture technology, which is applied to ships, dry docks, slipways, etc., can solve the problems of poor binding of scaffolding boards, waste of materials, and deflation, and achieve the effects of fast and convenient clamping, fast and convenient assembly, and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with drawings and embodiments.

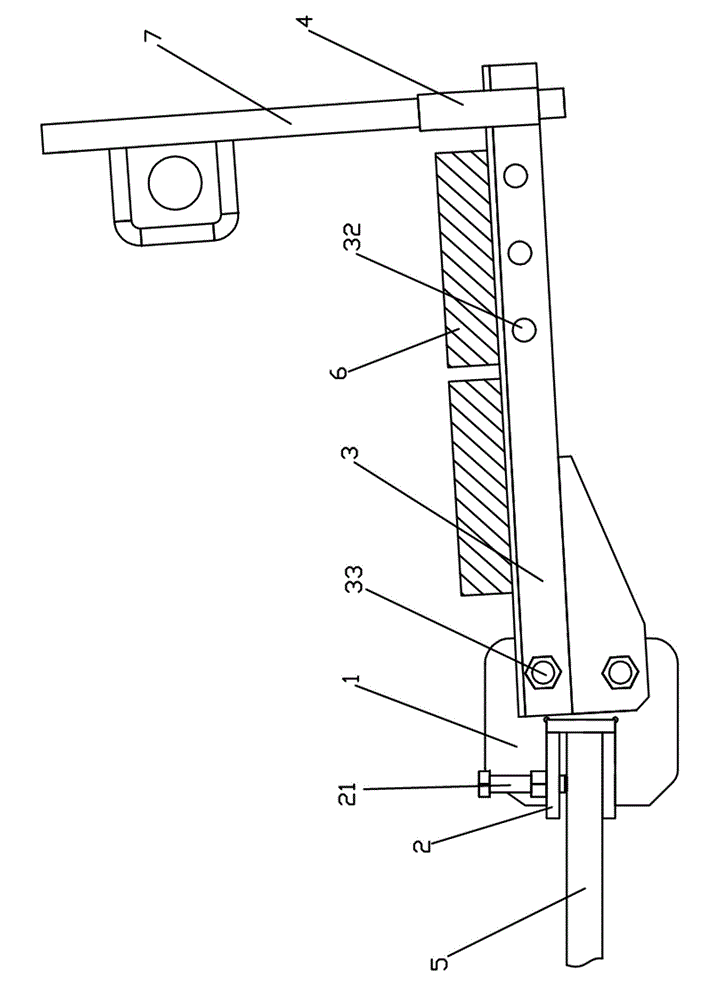

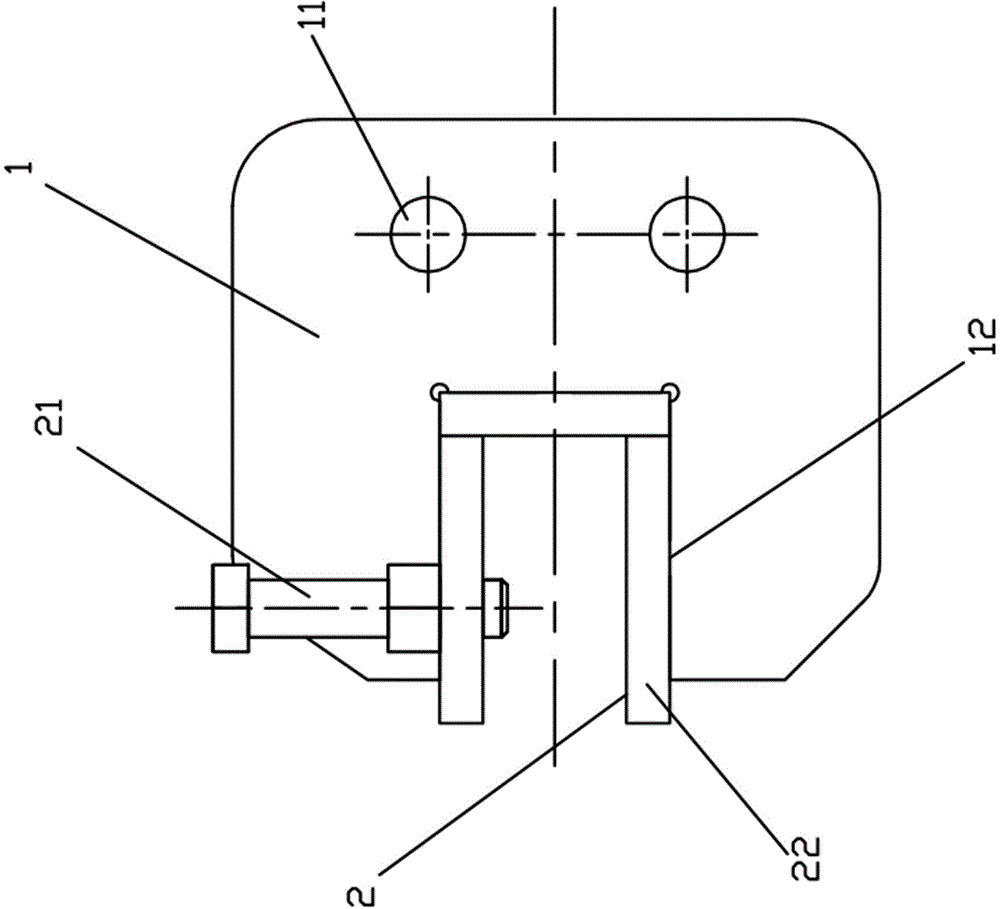

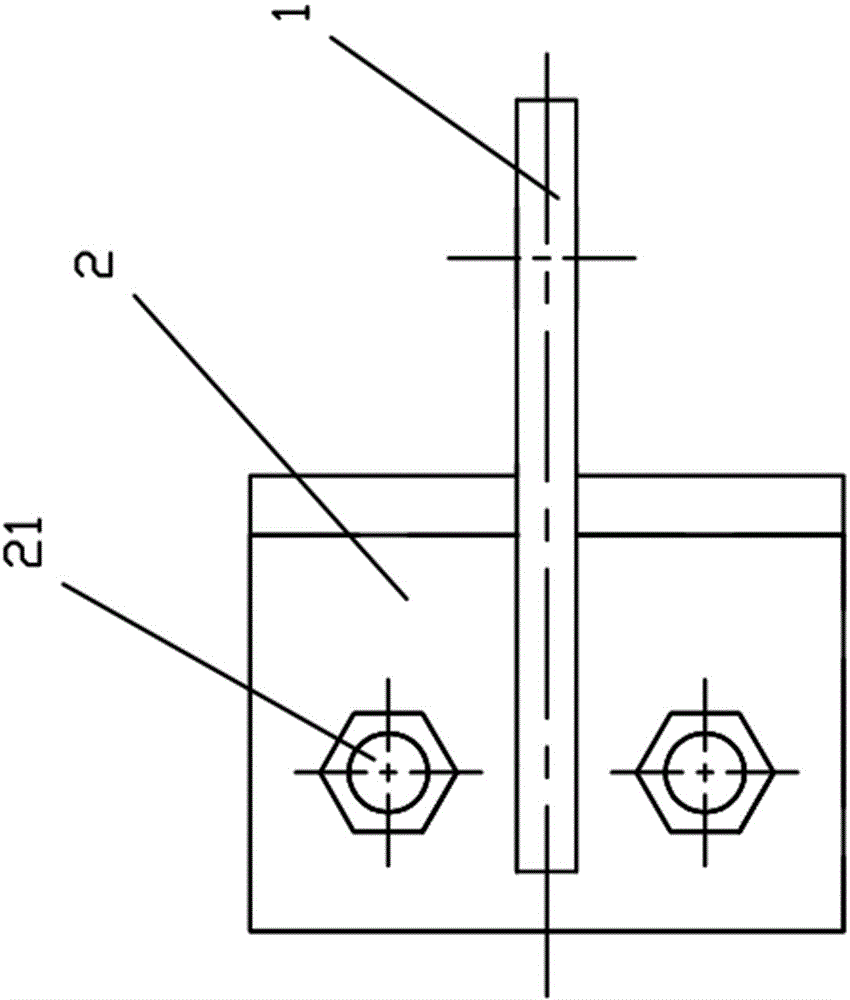

[0021] Such as figure 1 As shown, the present invention includes a panel 1, a socket 4, a support beam 3, and a U-shaped clamp 2; the U-shaped clamp 2 is fixedly arranged on the left side of the panel 1, and the insert 4 is fixedly arranged on the right end of the support beam 3, and supports Beam 3 is flexibly connected to panel 1; as figure 2 , image 3 As shown, the panel 1 is a plate, which is in a "U-shaped" shape as a whole, with a U-shaped opening 12 in the middle, and a support hole 11 at the upper and lower corners of the panel 1; The mouth 2 is welded by three steel plates 22, the cross section is "U" shape, the length direction of the U-shaped jaw 2 is symmetrically fixed in the U-shaped opening 12 of the panel 1, and the upper steel plate 22 is symmetrical to the panel 1 Each is provided with a fixing screw 21; the inserting sleeve 4 is a hollow tube; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com