Anti-inertial impact liquid tank with cylindrical helical tube inside

An inertial impact and helical technology, applied in the field of liquid tanks, can solve the problems such as the decline of the movement stability of the transportation tool, and achieve the effects of improving the movement stability and safety, reducing the offset of the center of gravity, and preventing the liquid inertial impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

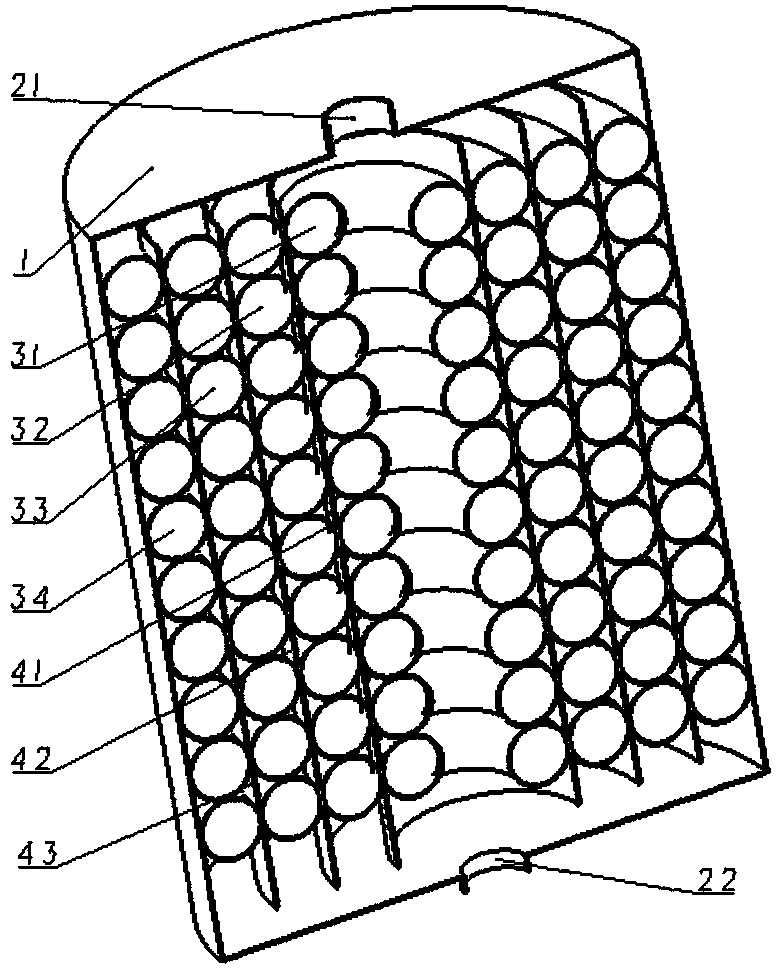

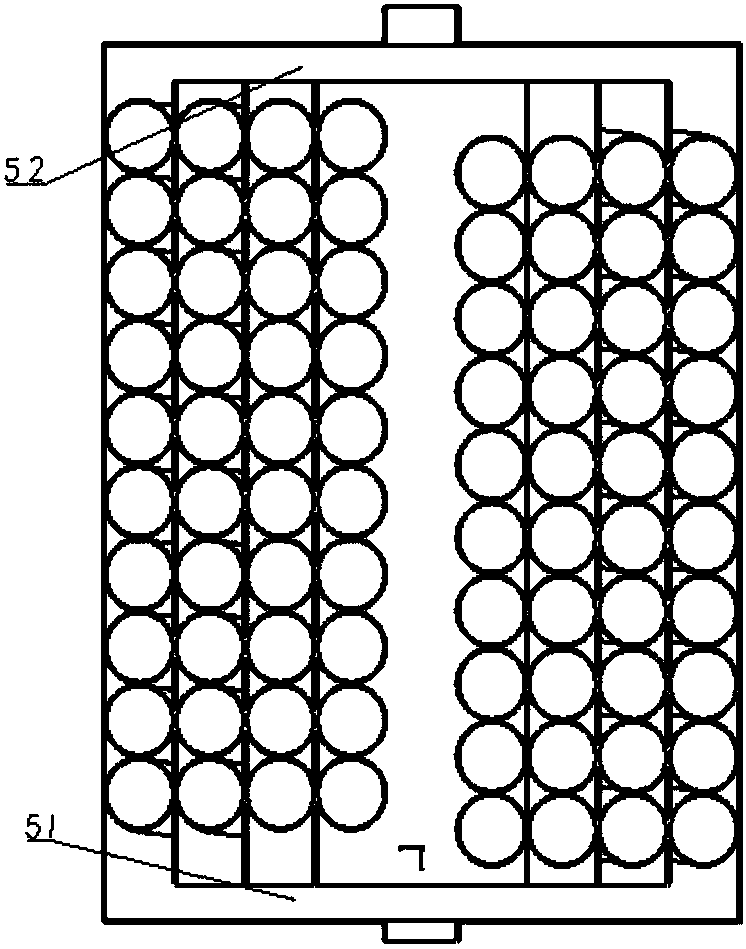

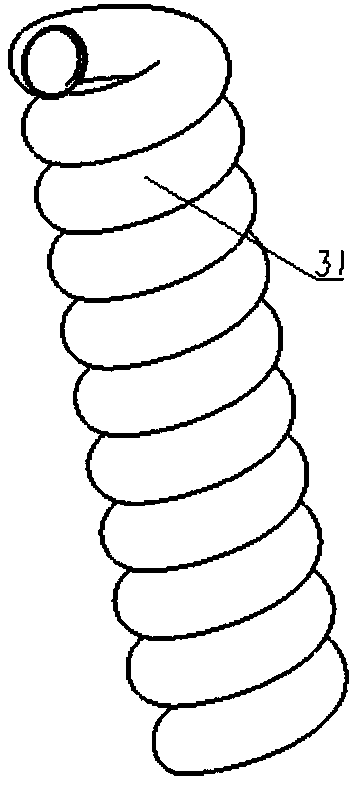

[0059] The liquid tank shown in Figure 1(a) and Figure 1(b) is equipped with four groups of coaxially arranged spiral tubes with a circular cross-section. The liquid is connected to the upper and lower parts of the liquid tank. The height range of 51 and 52 is 5-100 mm, and they are closely arranged spiral tubes 31, 32, 33 and 34 with different cylindrical helical radii. , 33, 34 are fixed on the cylindrical partitions 41, 42, 43 and the inner wall of the liquid tank side, and there are n types of cylindrical helical radii, respectively R(1), R(2)...R(n) , n takes 1, 2...12; N spiral tubes can be placed vertically closely at the position of the same cylindrical helix radius, and N takes 1, 2...10, Figure 1(c) is the same cylinder A schematic diagram of placing a helical tube closely at the helical radius position, and Fig. 1(d) is a schematic diagram of placing two helical tubes closely vertically at the same cylindrical helical radius position (that is, when N is 2).

[0060...

Embodiment 2

[0063] The liquid tank shown in Figure 2(a) and Figure 2(b) is equipped with four groups of coaxially arranged spiral tubes with a square cross-section inside. The spiral tubes are cylindrical, and the side length of the tube cross-section is d , then the lead of the helical tube is N×d; the helical radius of each cylinder r is taken as 3d; the diameter of the liquid tank shell 1 is R(n)×2+3d, and the rest are the same as in the first embodiment.

Embodiment 3

[0065] As shown in Fig. 3(a) and Fig. 3(b), the liquid tank is provided with four groups of coaxially arranged spiral tubes with triangular cross-sections inside. If the side length of the tube cross-section is d, the guide of the spiral tubes Cheng Wei Each cylindrical helix radius r is taken as 2d; the diameter of the liquid tank shell 1 is R(n)×2+2d, and the rest are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com