Decontamination device and method for a bottom grille

A grating and cleaning technology, applied in water conservancy projects, sea area projects, coastline protection, etc., can solve problems such as hidden safety hazards, low work efficiency, inconvenient operation, etc., to ensure safety, improve work efficiency, and save energy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

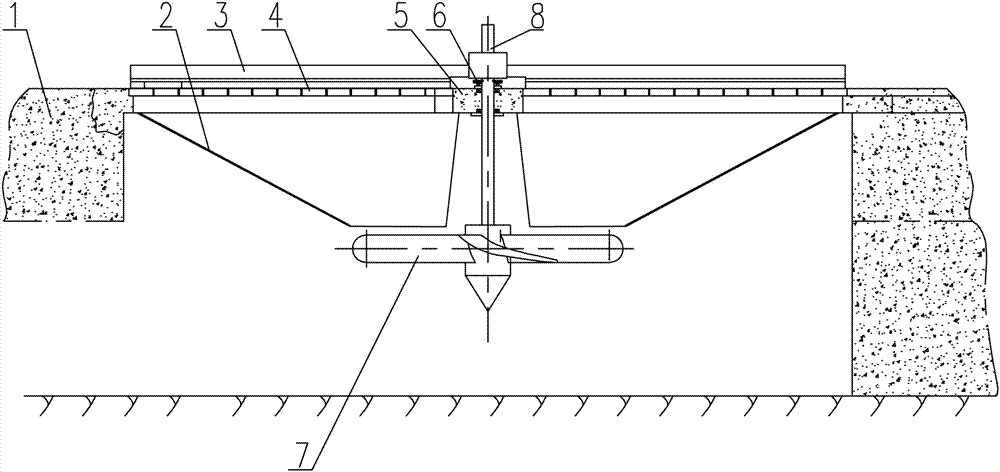

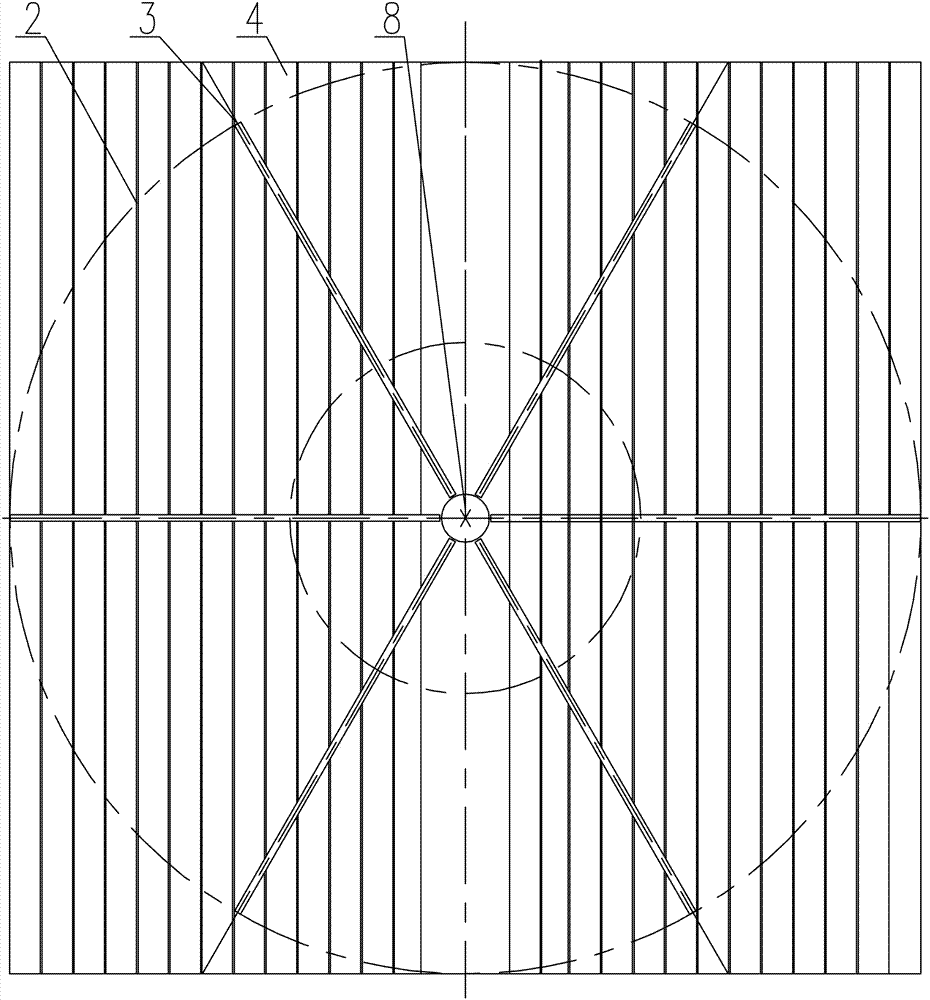

[0018] see Figure 1-2 , a cleaning device for the bottom grill, which includes a plane support seat 5, on which a main shaft 8 is vertically supported by a bearing 6, and the top of the main shaft 8 is fixedly equipped with a cleaning scraper 3, and the cleaning scraper The plate 3 fits with the upper surface of the bottom grid 4, the bottom of the main shaft 8 is fixedly fitted with runner blades 7, the lower surface of the bottom grid 4 is equipped with a confluence plate 2, and the water outlet of the confluence plate 2 is arranged on the rotary Just above the wheel blade 7. Through the above structure, the gravitational potential energy of the water flow can be converted into the kinetic energy of the blades of the runner, and then driven to rotate, driving the cleaning scraper 3 to perform cleaning treatment.

[0019] Further, through the gravitational action of the water flow, its gravitational potential energy is converted into the kinetic energy of the main shaft 8, ...

Embodiment 2

[0024] Adopt the cleaning method of the bottom grid grid cleaning device of implementation 1, the confluence plate 2 arranged on the bottom surface of the bottom grid grid 4 will collect the water to the bottom of the conical funnel, and the water after the confluence will impact the runner blade 7 , and then convert the gravitational potential energy of the water into kinetic energy, the runner blade 7 rotates under the action of the water flow, and then drives the main shaft 8 to rotate, and the rotation of the main shaft 8 will further drive the cleaning scraper 3 on the top to rotate, and the cleaning scraper 3 will The sludge on the upper surface of the bottom grid 4 is scraped and cleaned, and the scraped sludge or sundries will continue to be washed down to the bottom of the bottom grid 4 by the water flow.

[0025] Work process and working principle of the present invention are:

[0026] During the working process, water can be collected to the bottom of the conical fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com