A reaction frame for steel wire rope prestressed anchor cable tensioning

A technology of prestressed anchor cables and steel wire ropes, applied in the field of reaction frames, can solve problems such as low efficiency and high tension safety risks, achieve high safety performance, reduce labor intensity of workers, and improve tension efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

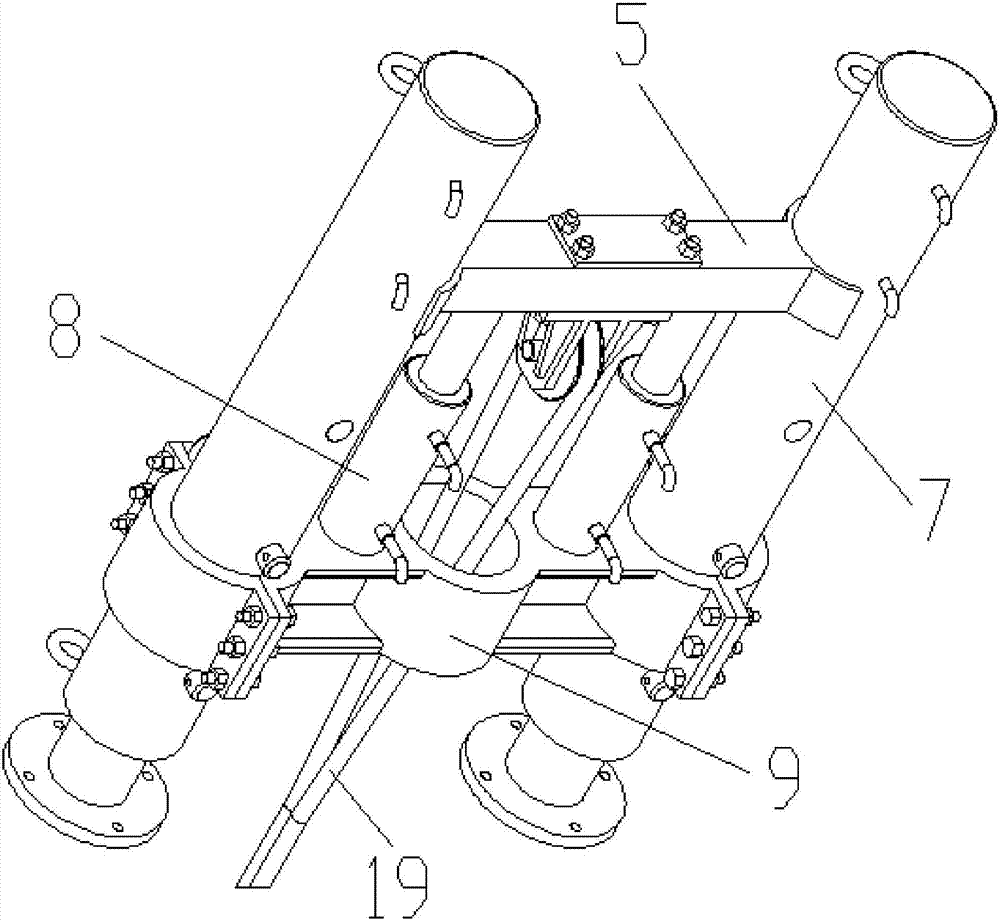

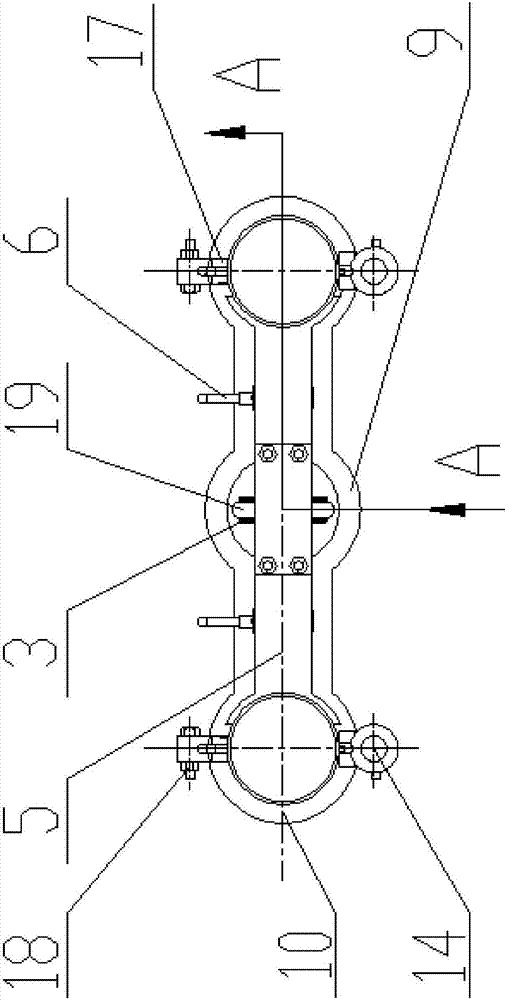

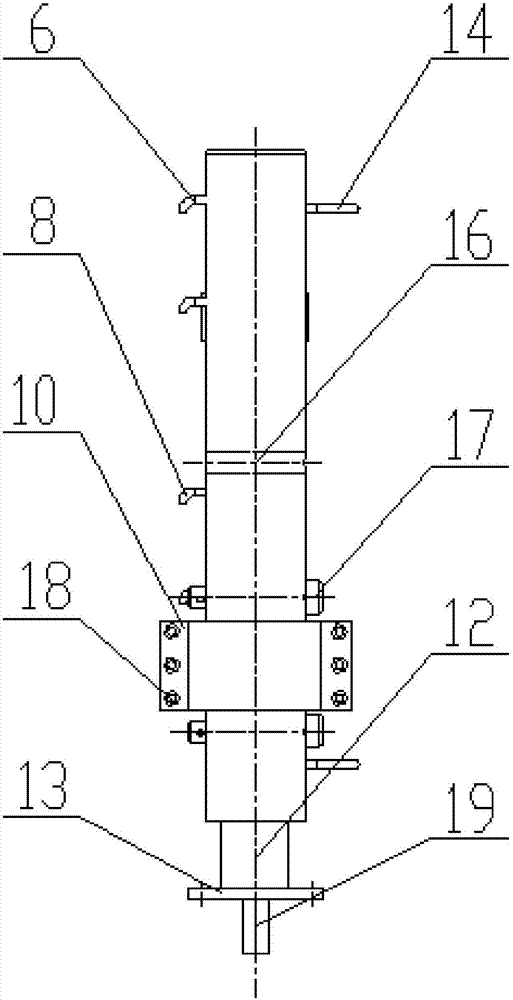

[0046] A reaction frame for tensioning steel wire rope prestressed anchor cables, comprising:

[0047] The movable crossbeam 5 can be connected and fixed with the annular insertion section of the wire rope anchor cable 19;

[0048] The tensioning hydraulic jack 8 is connected with the movable beam 5;

[0049] The fixed beam 9 is used to support the tensioning hydraulic jack 8, the fixed beam 9 is connected with the tensioning hydraulic jack 8, and the tensioning hydraulic jack 8 can make the movable beam 5 approach or move away from the fixed beam 9;

[0050] The guiding reaction force column 7 is connected with the fixed beam 9;

[0051] The adjustment mechanism can adjust the position of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com