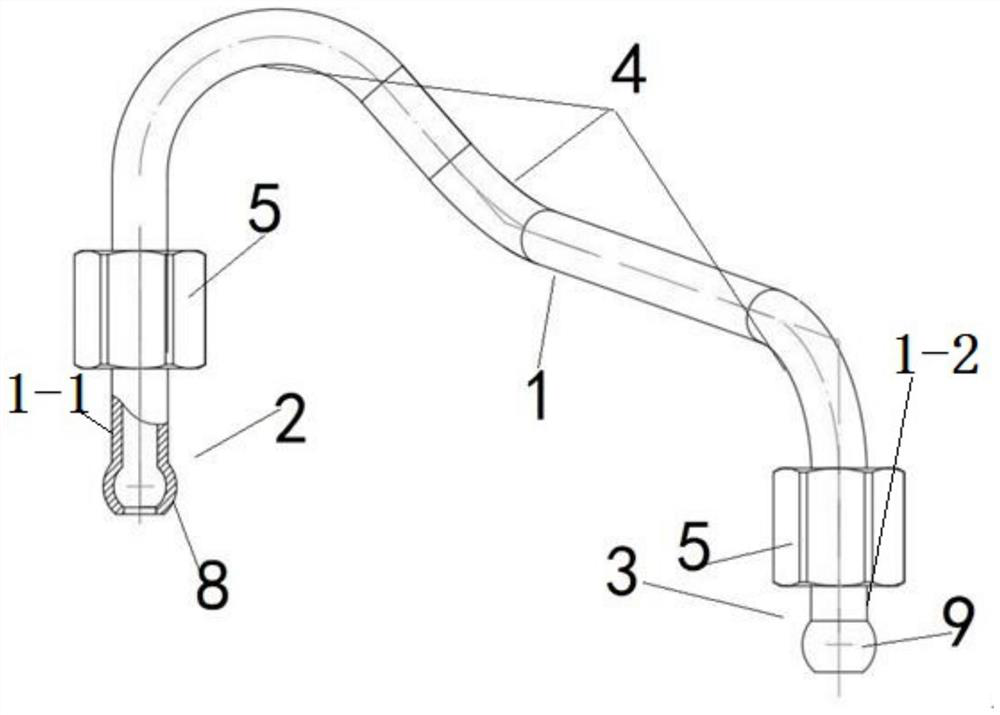

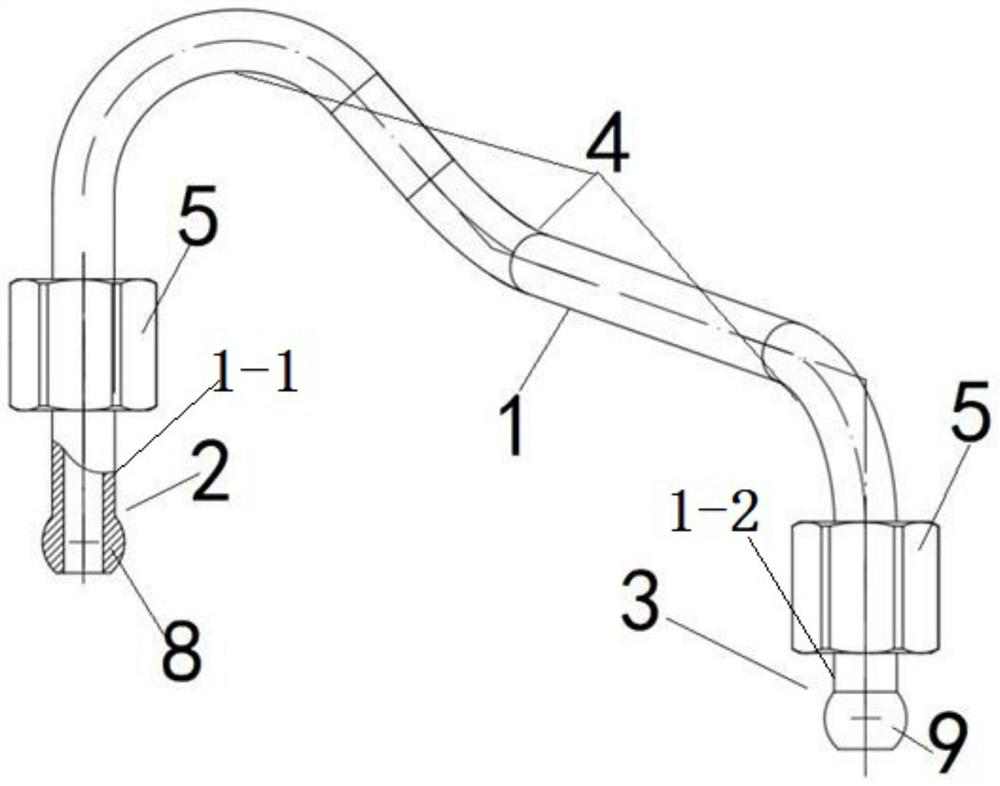

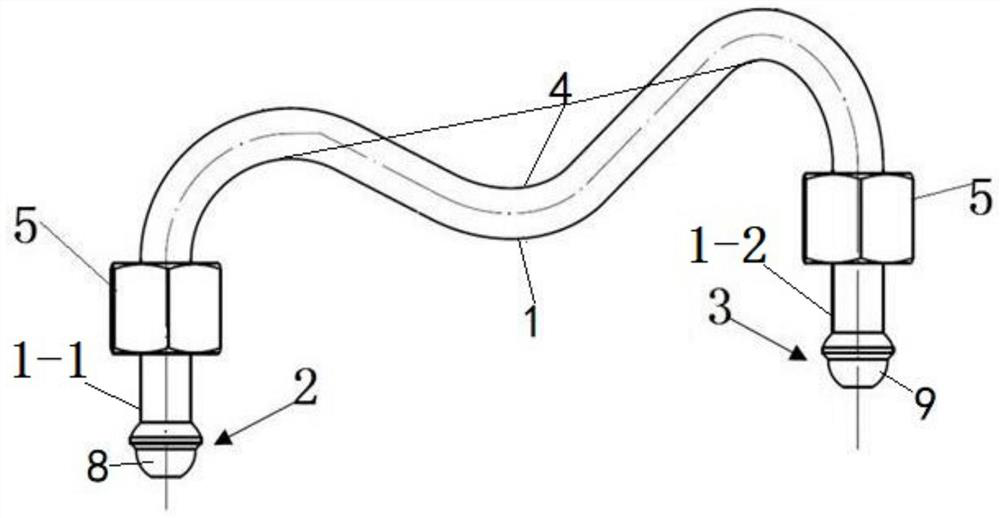

Stainless steel fuel high-pressure oil pipe and manufacturing process thereof

A high-pressure oil pipe and manufacturing process technology, which is applied to fuel injection devices, engine components, machines/engines, etc., can solve problems such as the decline in nut locking performance and the reliability of oil pipe sealing, so as to reduce the rigidity of the body and ensure the axial force , to ensure the effect of sealing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 5

[0124] Specific embodiment 5, a kind of stainless steel fuel high-pressure fuel pipe provided in this embodiment 5 is the same as a stainless steel fuel high-pressure fuel pipe in specific embodiment 1, only the manufacturing process steps of a stainless steel fuel high-pressure fuel pipe in this embodiment 5 are simpler, It includes the following steps:

[0125] Step S1: After the raw stainless steel straight pipe is cut off, the port at one end of the stainless steel straight pipe is subjected to the first cold forming process;

[0126] Step S2: performing high-temperature annealing on the port at one end of the stainless steel straight pipe processed by the first cold forming to form a soft sealing joint 2;

[0127] Step S3: Insert two back-to-back nuts 5 through the unprocessed other end port of the stainless steel straight pipe;

[0128] Step S4: Cold forming the unprocessed other end port of the stainless steel straight pipe to form a hard-sealed joint 3;

[0129] Step...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com