Electromagnetic actuator

An electromagnetic actuator and electromagnetic force technology, applied in non-mechanically actuated valves, magnets, circuits, etc., can solve the problems of reduced magnetic transmission, insufficient generation of repulsive force, attractive force, and induced electromotive force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

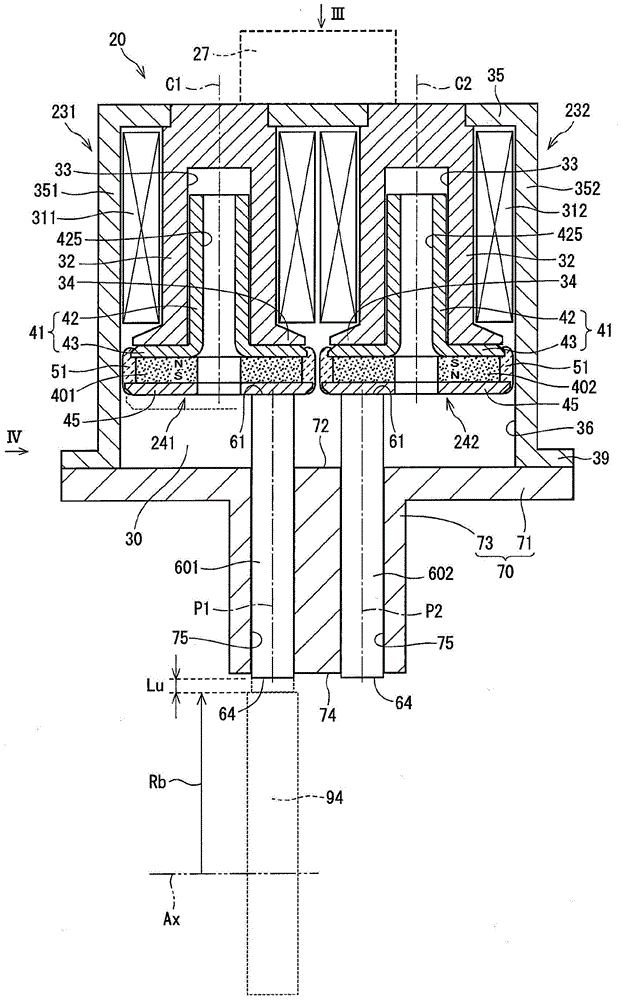

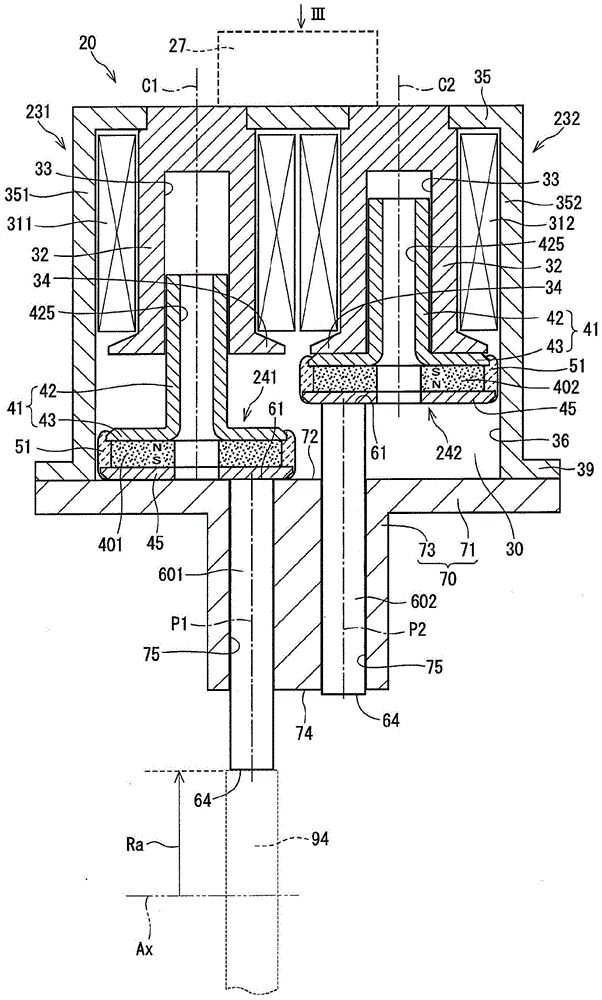

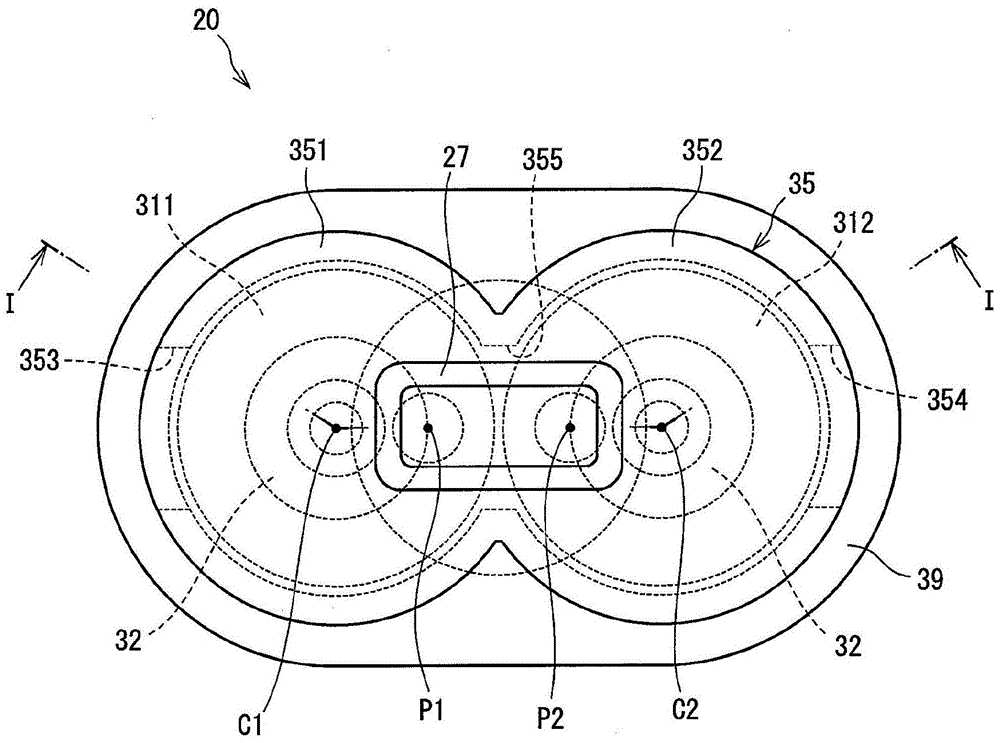

[0016] The electromagnetic actuator according to the embodiment will be described below based on the drawings. The electromagnetic actuator is applied to a valve lift adjusting device that adjusts the lift amount of the intake valve or exhaust valve of an internal combustion engine.

[0017] Will be based on figure 1 To FIG. 6 describes the configuration of the electromagnetic actuator of one embodiment. Such as Figure 1 to Figure 4 As shown, the electromagnetic actuator 20 of this embodiment is a "two-pin type" electromagnetic actuator, and actuates any one of the two output pins 601, 602 to the camshaft 94 of the valve lift adjusting device.

[0018] In order to actuate the two output pins 601, 602 individually, the electromagnetic actuator 20 has two sets of stationary parts 231, 232 including coils 311, 312, etc., and two sets of movable parts including permanent magnets 401, 402, etc., respectively 241,242. Therefore, in addition to a part of the common components, most of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com