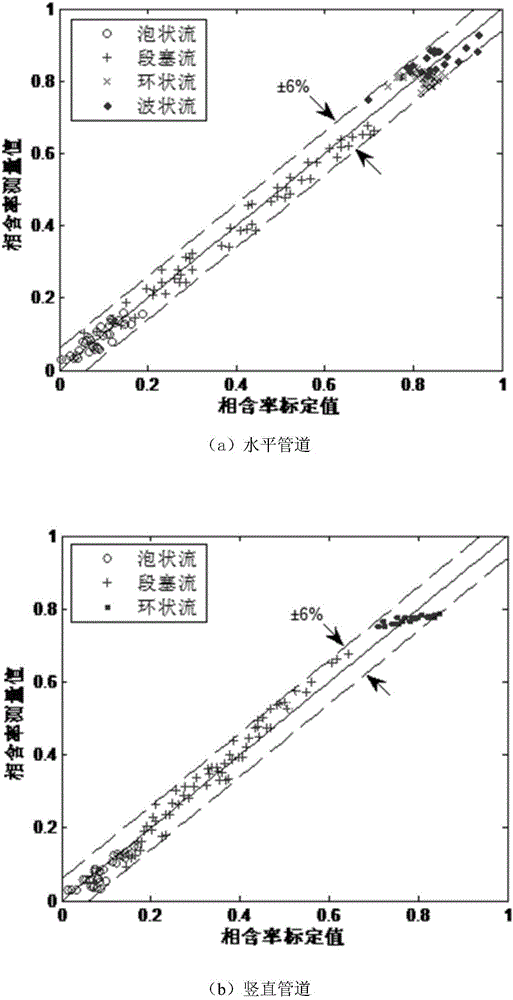

Multi-vision-based system and method for measuring gas-liquid two-phase flow phase fraction of small channel

A technology of gas-liquid two-phase flow and small channels, which is applied to measuring devices, material analysis through optical means, instruments, etc., can solve the problems of insufficient information acquisition and insufficient accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

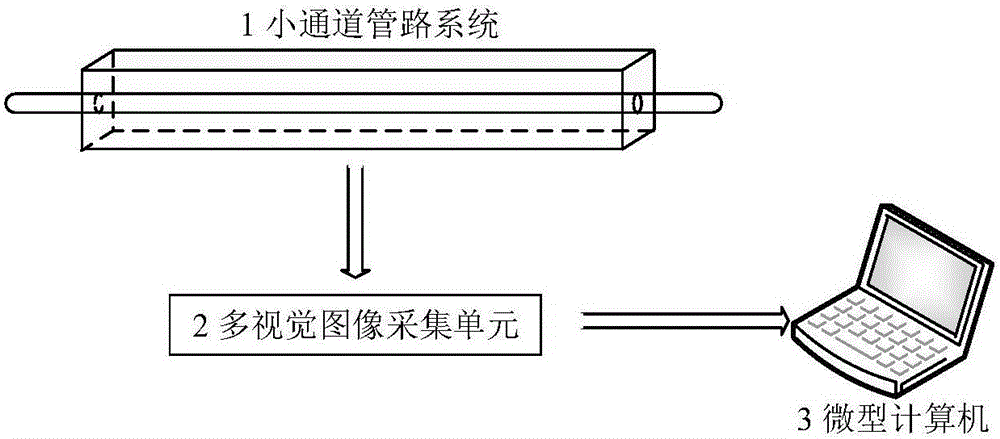

[0043] Refer to attached figure 1 , the present invention utilizes the small channel gas-liquid two-phase flow phase holdup measurement system based on multi-vision to realize the small channel gas-liquid two-phase flow phase holdup measurement. The small-channel gas-liquid two-phase flow holdup measurement system based on multi-vision includes three parts: a small-channel piping system, a multi-vision high-speed image acquisition unit and a microcomputer.

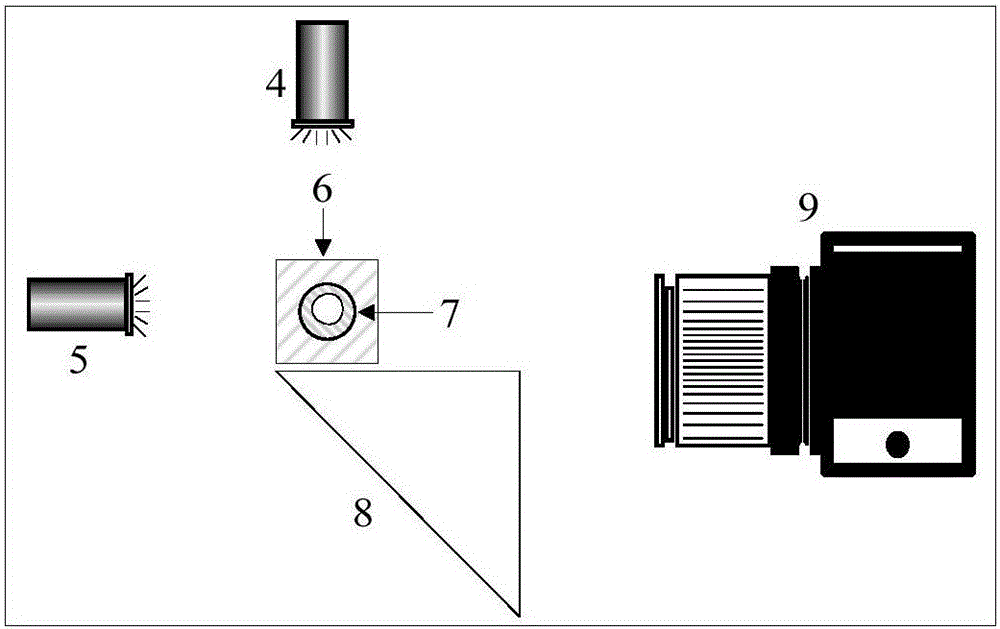

[0044] like figure 2 As shown, the small channel pipeline system 1 is composed of a small channel 7 immersed in a glycerin tank 6, and the multi-vision high-speed image acquisition unit 2 is composed of a high-speed camera 9, a rectangular prism 8, a first LED light source 4, and a second LED light source 5. The multi-vision high-speed image acquisition unit is responsible for simultaneously collecting two gas-liquid two-phase flow images at mutually perpendicular angles, and the images collected by the multi-vision hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com