Numerical simulation of scrap trimming operations in sheet metal forming

A metal sheet, trimming technology, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve problems such as error-prone, manual creation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

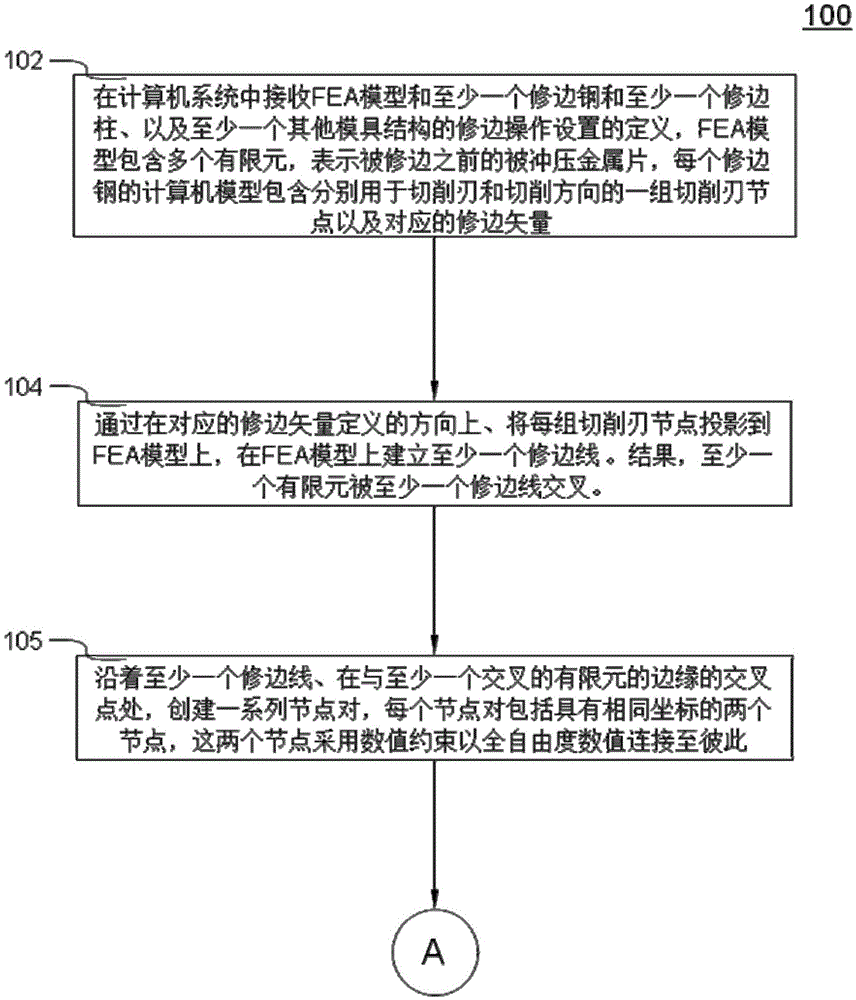

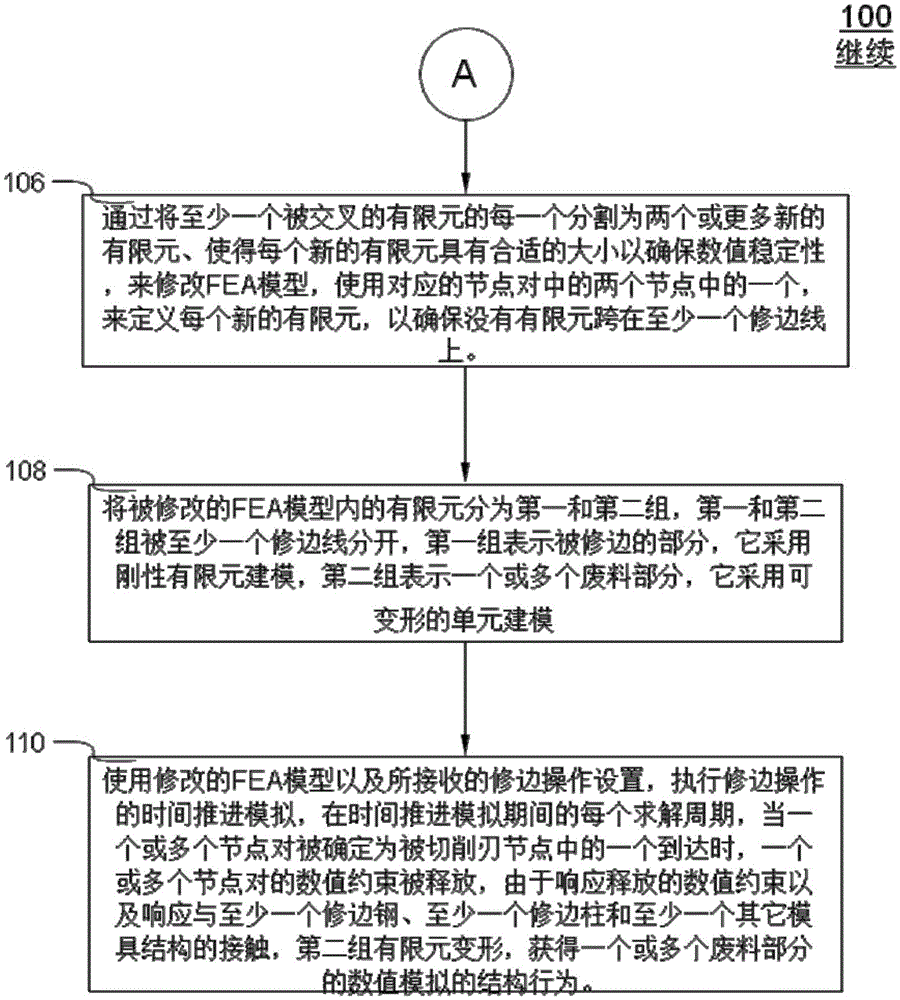

[0024] First refer to Figures 1A-1B , which collectively illustrate a flowchart of an exemplary process 100 for performing a time-marching simulation of scrap trimming operations in sheet metal forming in accordance with embodiments of the present invention.

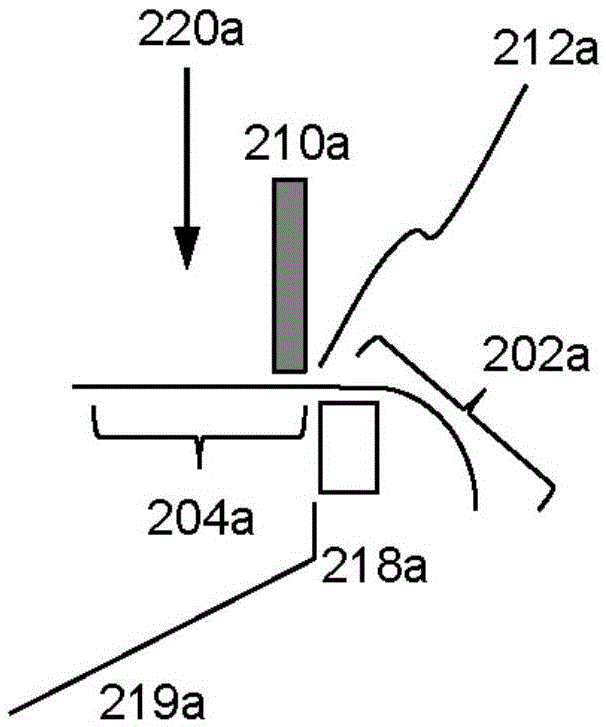

[0025] Process 100 begins at act 102 with a computer system on which an application module is installed (eg, Figure 10 The computer system 100) receives a definition of a FEA model and trimming operation settings, the FEA model containing a plurality of finite elements (eg, two-dimensional shell elements) to represent the stamped sheet metal before the scrap portion is trimmed. The FEA model may be a sheet metal model obtained after a numerically simulated stamping operation. The trimming operation setup includes a computer model of at least one trimming steel and at least one trimming post, and at least one other mold structure (eg, a waste chute). The computer model of each of the at least one trimming steel include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com