Speed control device of hydraulic actuator

A technology of speed control device and hydraulic actuator, which is applied in engine control, hoisting device, transportation and packaging, etc. It can solve problems such as easy failure, multiple sensors, and small production quantity, and achieve reliable speed control and mode change Simple, effective price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

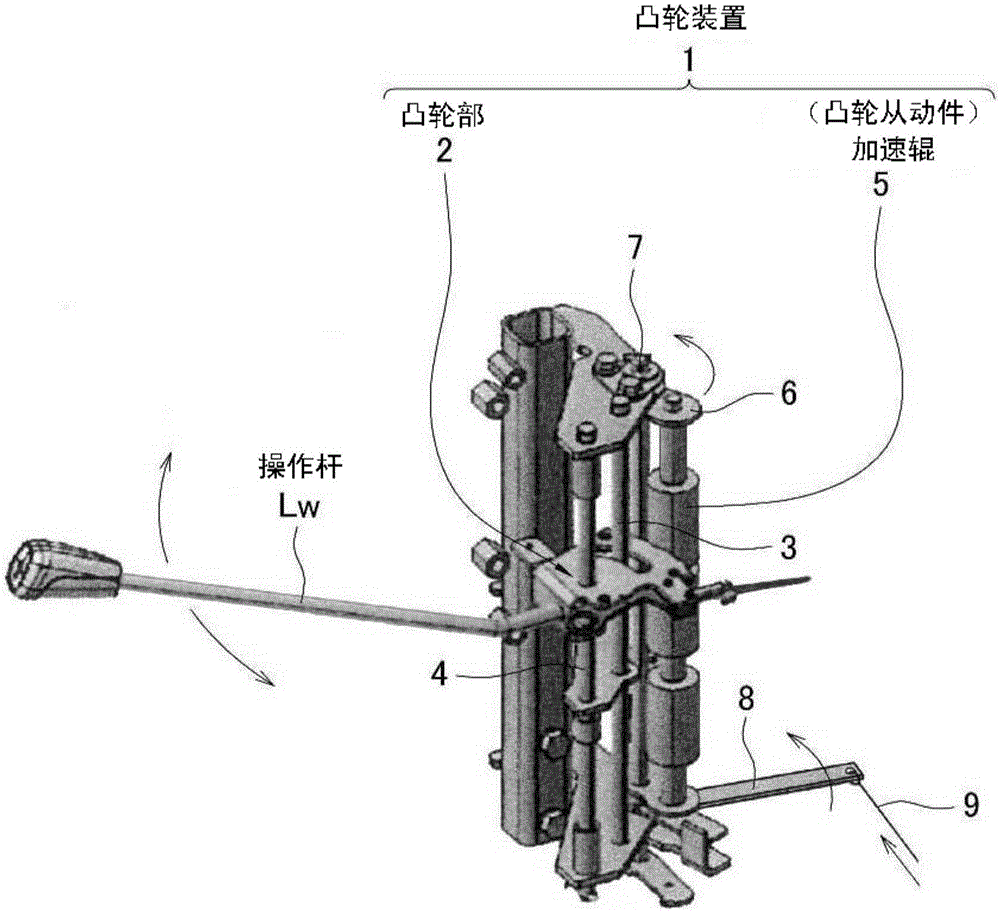

[0059] Next, based on Figure 3 ~ Figure 5 The cam unit 2 of the first embodiment will be described.

[0060] Such as image 3 As shown, the cam unit 2 includes a high-speed cam 10 and a normal cam 20 . The high-speed cam 10 is a plate material bent into a "U" shape in side view, and its base is attached to the base of the operation lever Lw. In addition, a hole 11 and a guide groove 12 through which the aforementioned support shaft 4 passes are formed on the cam plate of the high-speed cam 10 .

[0061] The high-speed cam 10 can be fixed to the fulcrum 4 of the through hole 11 so that the fulcrum 4 can rotate freely, or the fulcrum 4 can be fixed and the high-speed cam (and thus the whole of the cam portion 2) can tilt left and right around the hole 11.

[0062] The guide groove 12 is bent, figure 1 The shown guide shaft 3 passes through the inside of the guide groove 12, thereby guiding the lateral tilt of the cam portion 2 and restricting the stroke end.

[0063] Such ...

no. 2 Embodiment approach

[0109] based on Figure 6 ~ Figure 8 The cam device 1 of the second embodiment will be described.

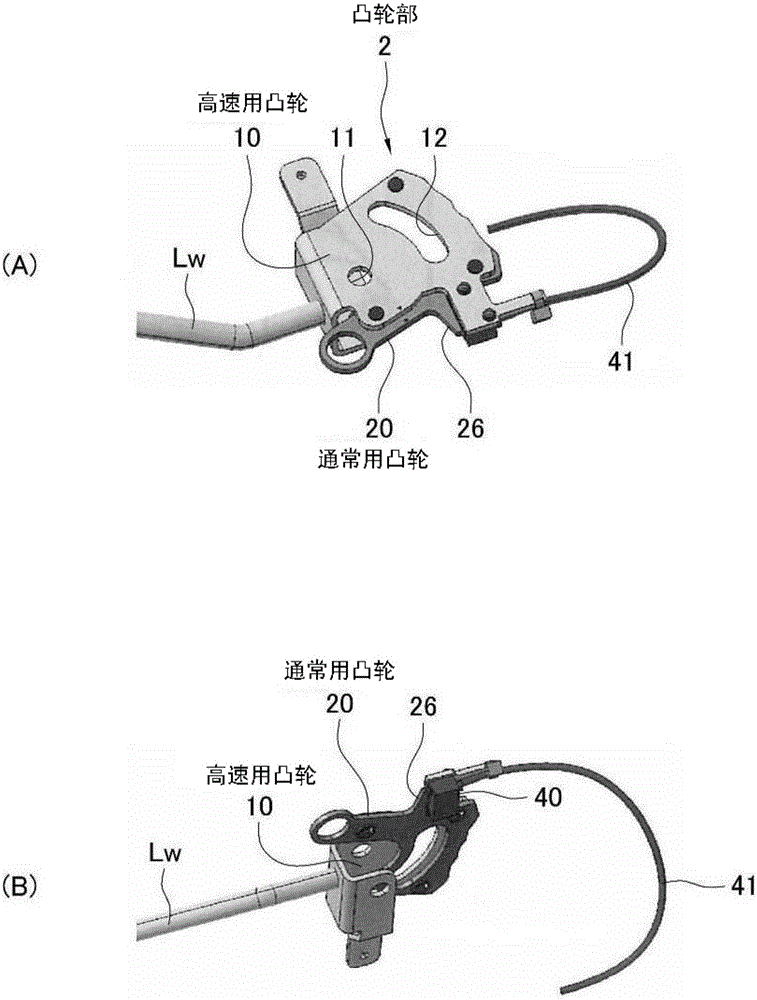

[0110] constitute Image 6 The high-speed cam 10 and the normal cam 20 of the cam unit 2 shown in (A) are the same as those in the first embodiment. The present embodiment is characterized in that a switch driving member is not formed on the normal cam 20, but a switch driving plate 30 dedicated to switch switching operation is provided. On the switch driving board 30 is formed a pressing piece 31 for turning on and off the changeover switch 40 .

[0111] Such as Image 6 As shown in (B), the switch driving plate 30 is arranged on the back surface of the normal cam 20 and is attached so as to be slidable with respect to the guide pin 17 through a long hole (not shown). In addition, it is always pushed toward the accelerator roller 5 side by an appropriate urging mechanism (not shown) such as a spring, but is pushed back by the accelerator roller 5 when it comes into contact ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com