Dairy fan processing machine

A processing machine and milk fan technology, applied in dairy products, cheese substitutes, applications, etc., can solve problems such as inability to compact, uneven thickness of milk fans, easy breakage of milk fans, etc., to facilitate packaging and expand market sales. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

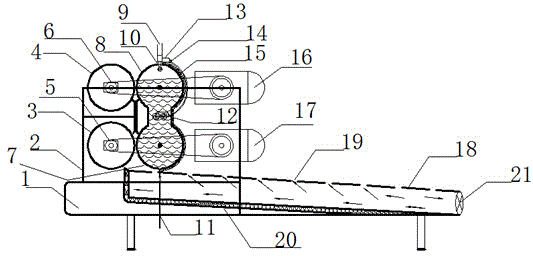

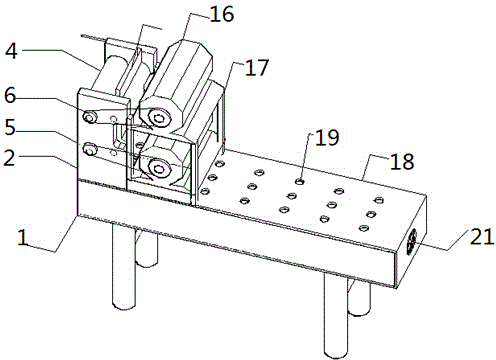

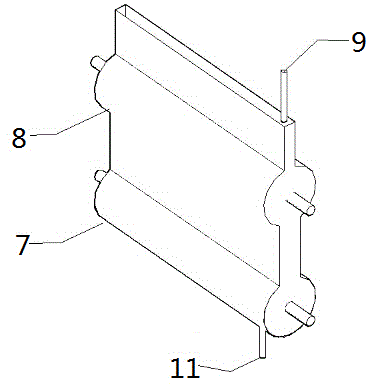

[0016] like Figure 1-3 As shown, the milk fan processing machine mainly includes a base 1, a casing 2, a rotatable pressure roller I3, a rotatable pressure roller II4, a speed controller I5, a speed controller II6, a temperature-controlled pressure roller I7, and a temperature-controlled pressure roller I7. Pressure control roller Ⅱ8, water inlet 9, floating ball 10, water outlet 11, heating pipe 12, temperature control sensor 13, power switch 14, insulation material Ⅰ15, motor Ⅰ16, motor Ⅱ17, hot air pipe 18, hot air pipe microholes 19. Insulation material II20, hot air blower 21; the rotatable pressure roller I3, the base 1, and the rotatable pressure roller II4 are kept on the same level as the axes of the fixed temperature-controlled pressure roller I7 and temperature-controlled pressure roller II8 respectively , and a certain gap is left, the temperature-controlled pressure roller I7 and the temperature-controlled pressure roller II8 are hollow, with a built-in heating t...

Embodiment 2

[0019] like Figure 1-3 As shown, the milk fan processing machine mainly includes a base 1, a casing 2, a rotatable pressure roller I3, a rotatable pressure roller II4, a speed controller I5, a speed controller II6, a temperature-controlled pressure roller I7, and a temperature-controlled pressure roller I7. Pressure control roller Ⅱ8, water inlet 9, floating ball 10, water outlet 11, heating pipe 12, temperature control sensor 13, power switch 14, insulation material Ⅰ15, motor Ⅰ16, motor Ⅱ17, hot air pipe 18, hot air pipe microholes 19. Insulation material II20, hot air blower 21; the rotatable pressure roller I3, the base 1, the rotatable pressure roller I3 and the rotatable pressure roller II4 are respectively connected to the shafts of the fixed temperature-controlled pressure roller I7 and temperature-controlled pressure roller II8 The center is kept on the same level with a certain gap. The shaft on the side of the rotatable pressure roller I3 meshes with the speed gove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com