Polishing rubbing block for ceramic tile polishing equipment

A polishing, grinding and equipment technology, which is applied to metal processing equipment, wheels and abrasives of flexible working parts, and can solve problems such as incomplete tile color and achieve the effect of complete color, smoothness and uniform gloss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order for those skilled in the art to better understand the technical solutions provided by the present invention, the following will be described in conjunction with specific embodiments.

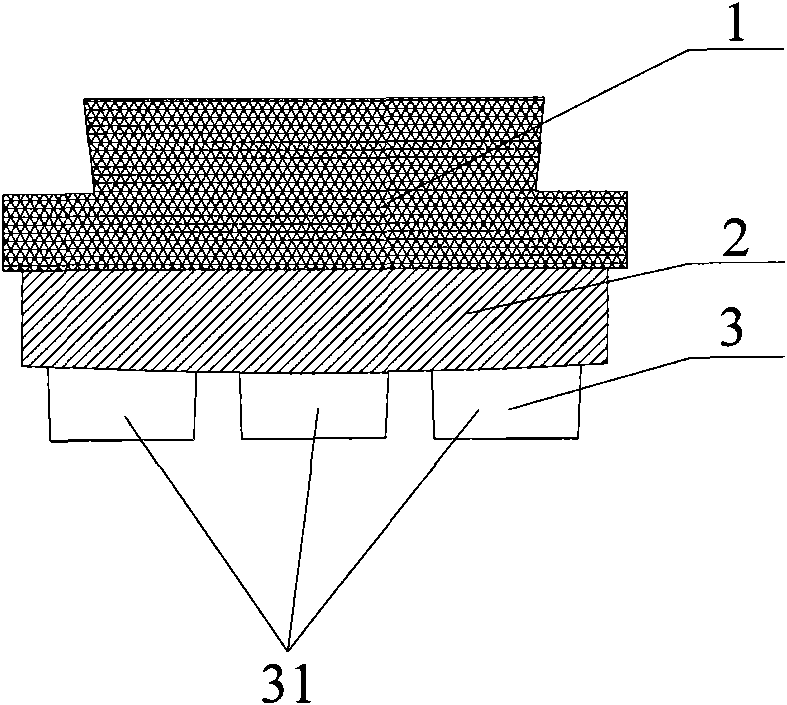

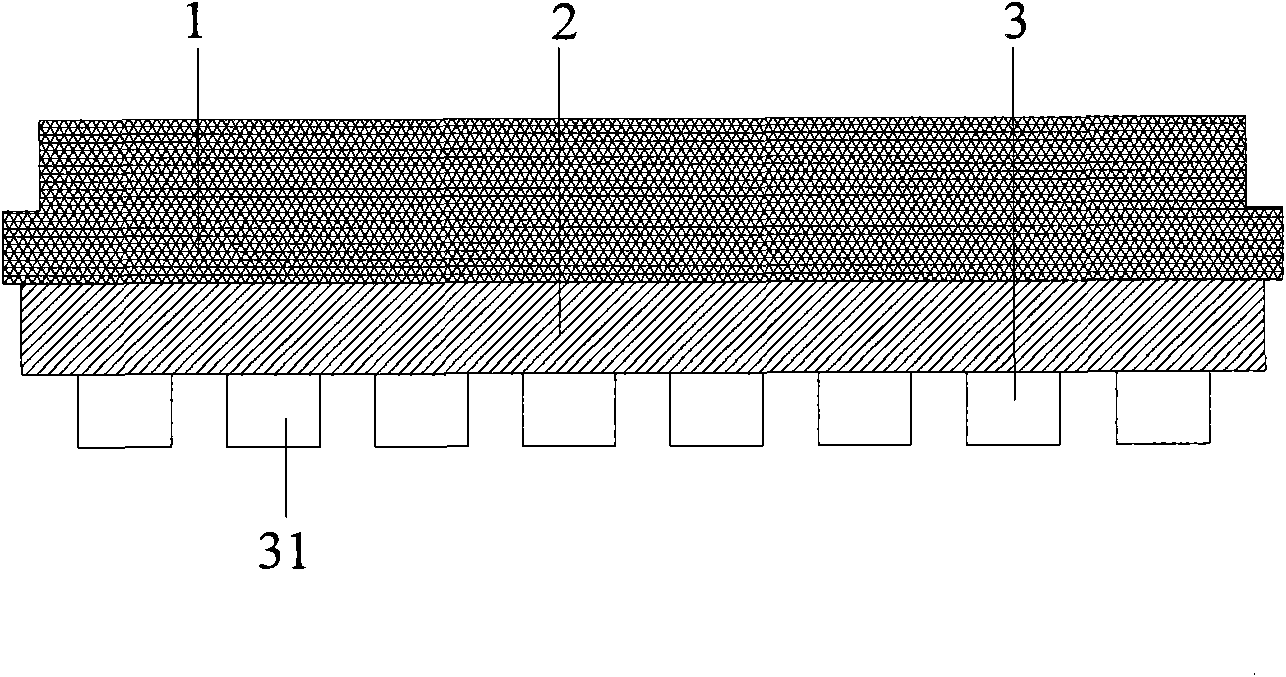

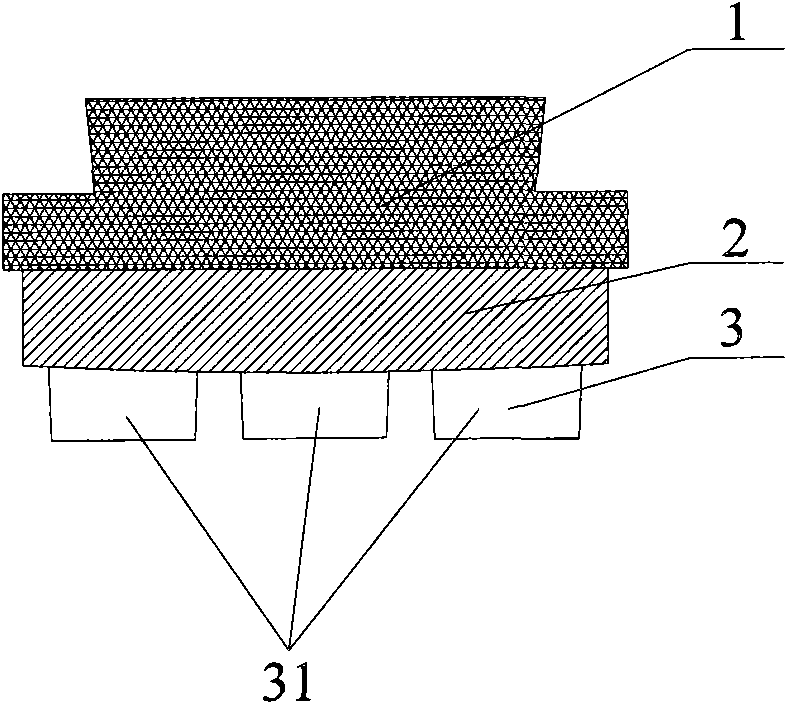

[0013] See figure 1 , figure 2 figure 1 It is a side view in the width direction of the polishing block used for tile polishing equipment in the present invention; figure 2 It is a side view along the length direction of the polishing abrasive block used in the ceramic tile polishing equipment in the present invention.

[0014] The polishing grinding block used for ceramic tile polishing equipment provided by the present invention includes a frosted layer and an assembly, and a buffer layer is arranged between the frosted layer and the assembly, and the buffer layer is made of elastic plastic material. The frosted layer is composed of 24 discontinuous small grinding blocks, and the 24 small grinding blocks are arranged regularly, with 8 rows in the length direction and 3 row...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com