A chain furnace for co-combustion of biomass and domestic waste and its operating method

A technology of domestic waste and operation method, applied in the field of chain furnace, can solve the problems of low energy conversion efficiency and system instability, and achieve the effect of realizing resource utilization, clear operation principle and improving combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

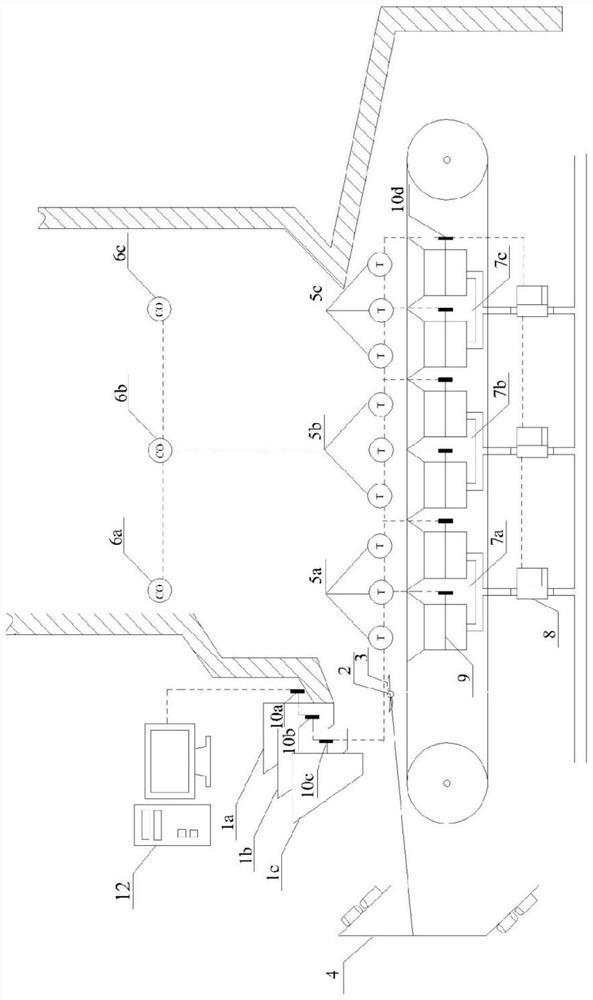

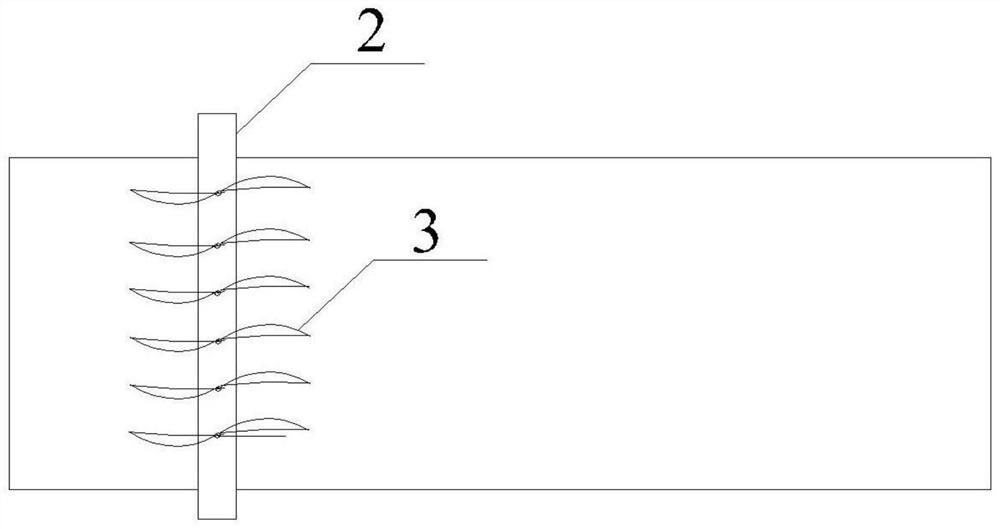

[0030] Such as figure 1 As shown, a chain furnace for the co-combustion of biomass and domestic waste includes a chain furnace body, a feeding device, a temperature measuring device, a flue gas measuring device, and an air distribution device. The fuel is delivered to the furnace through the three-layer hopper. The first hopper 1a is used to transport biomass fuel, the second hopper 1b is used to transport domestic waste fuel, and the third hopper 1c is used to transport biomass fuel. The three-layer hopper is respectively connected to the first The regulator 10a, the second regulator 10b, and the third regulator 10c are connected to adjust the feed rate of the chain furnace. The final fuel is divided into three layers, which are biomass, domestic garbage, and biomass from top to bottom.

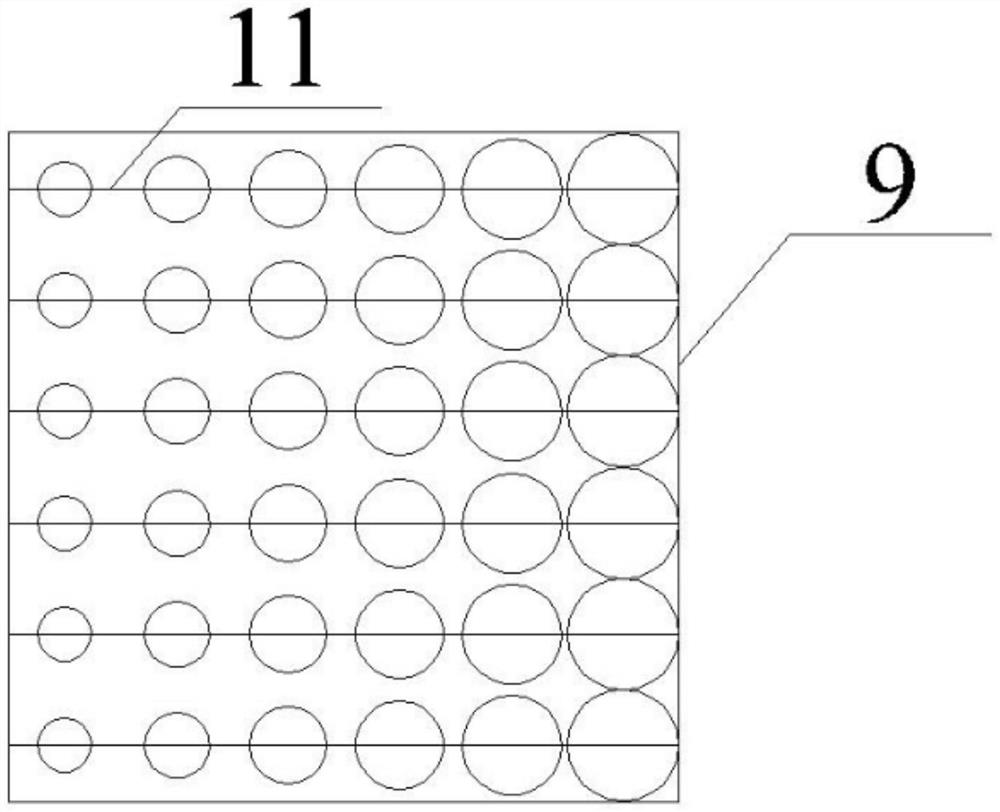

[0031] The air distribution device divides the chain furnace air chamber into three groups, which are the first air part 7a, the second air part 7b and the third air part 7c in sequence. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com