Method and device for improving room temperature forming performance of magnesium alloy

A formability and magnesium alloy technology, which is applied in the field of metal processing, can solve the problems of unfavorable subsequent forming, unsatisfactory mechanical properties of sheets, and restrictions on the application of magnesium alloy sheets.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

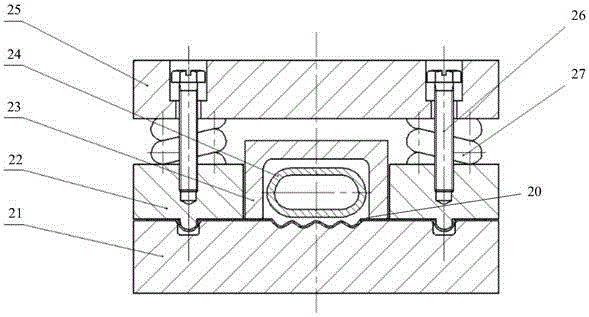

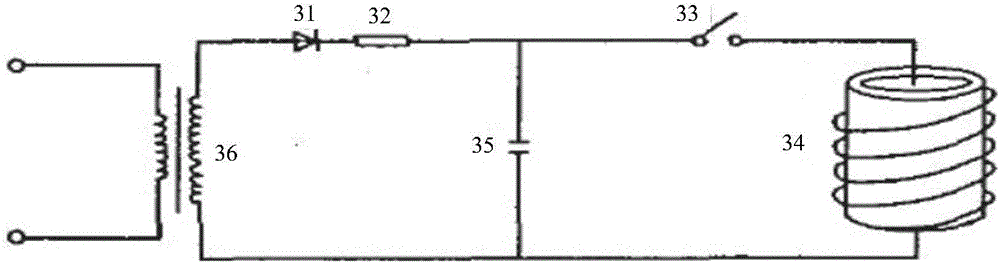

[0029] In order to overcome the defects existing in the prior art, the present invention provides a method and device for improving the forming performance of magnesium alloy at room temperature, using the high strain rate deformation method of electromagnetic forming to increase the twin ratio in the magnesium alloy plate, and using two micro-deformations , breaking the microstructure state of the strong basal texture caused by conventional rolling, thereby fundamentally changing the room temperature formability of magnesium alloy sheets. Since the whole process is at room temperature, processes such as homogenization treatment are avoided, and the production efficiency of the magnesium alloy plate is improved.

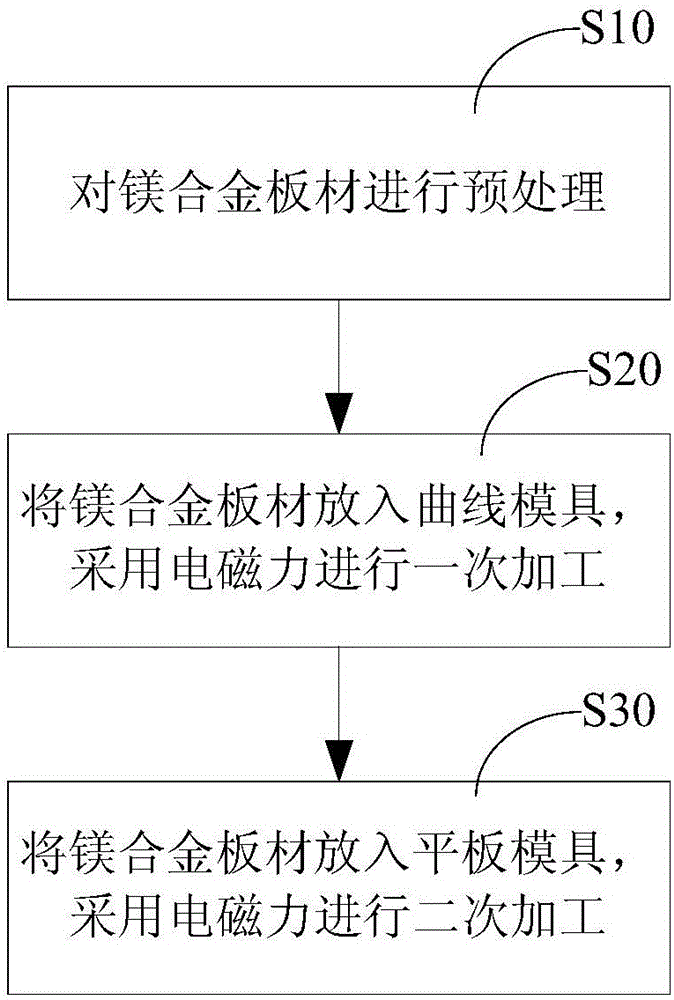

[0030] Such as figure 1 As shown, the method for improving room temperature formability of magnesium alloys includes the following steps:

[0031] S10: Pretreating the magnesium alloy plate.

[0032] The thickness of the magnesium alloy sheet to be treated is gener...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strain rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com