Clamping device

A clamping device and clamping technology, used in workpiece clamping devices, metal processing, metal processing equipment, etc., can solve the problems of low assembly qualification rate, inability to meet the requirements of concentricity, and bloated equipment, and achieve the highest qualification rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

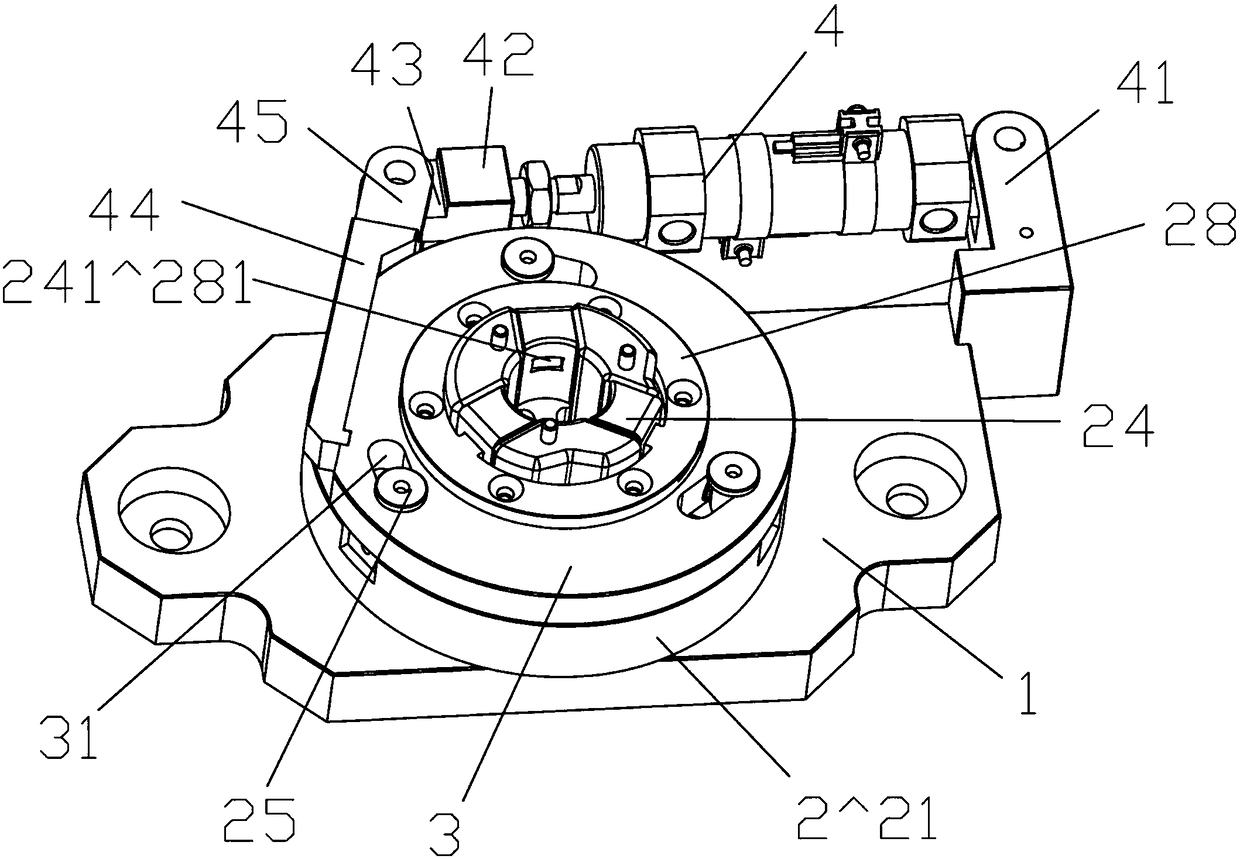

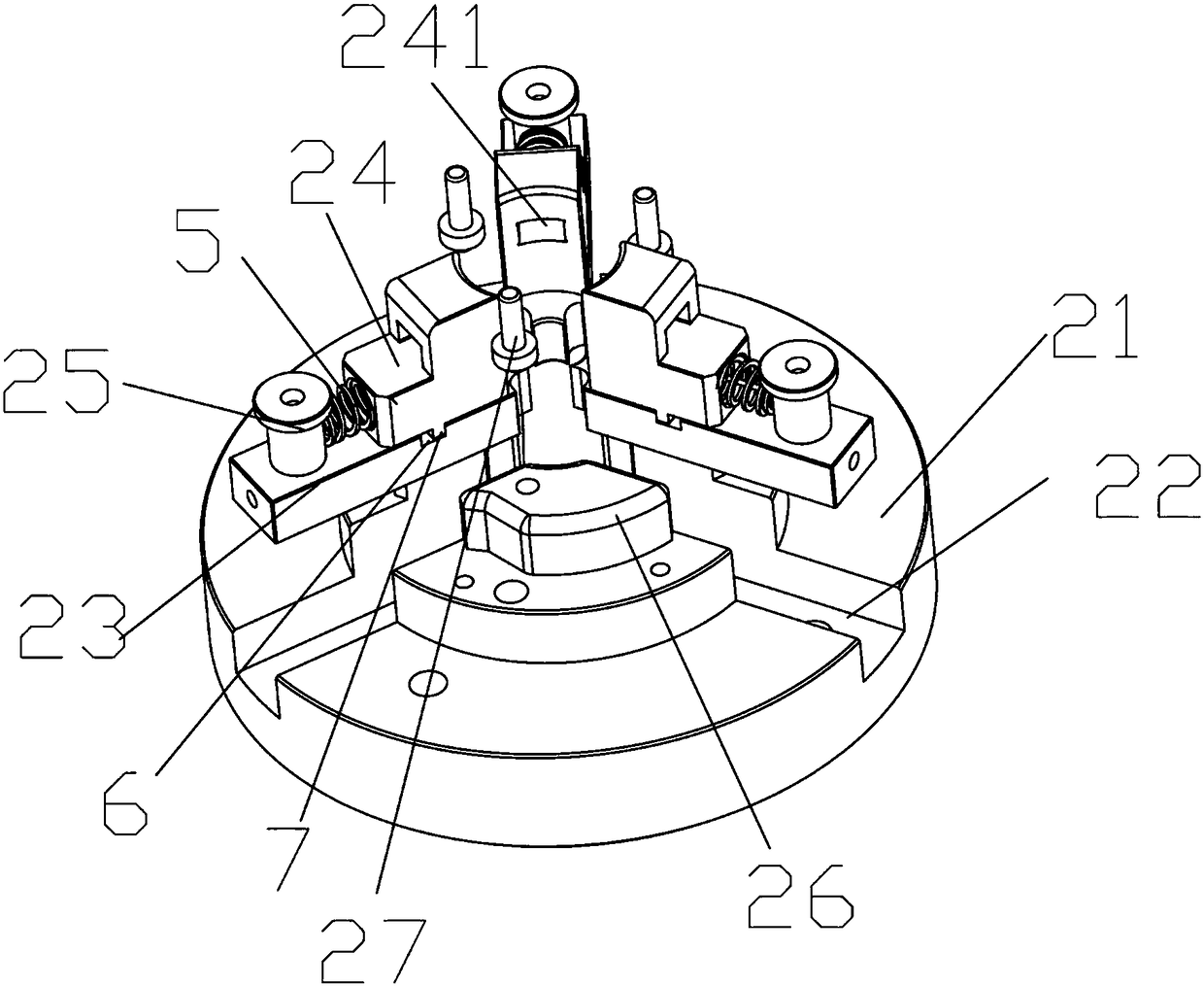

[0030] Reference Figure 1-3 , This embodiment provides a clamping device, including a bottom plate 1, a clamping assembly 2 arranged on the bottom plate 1, and a clamping cylinder 4 arranged on the bottom plate 1 and connected with the cylinder shaft and the clamping assembly 2;

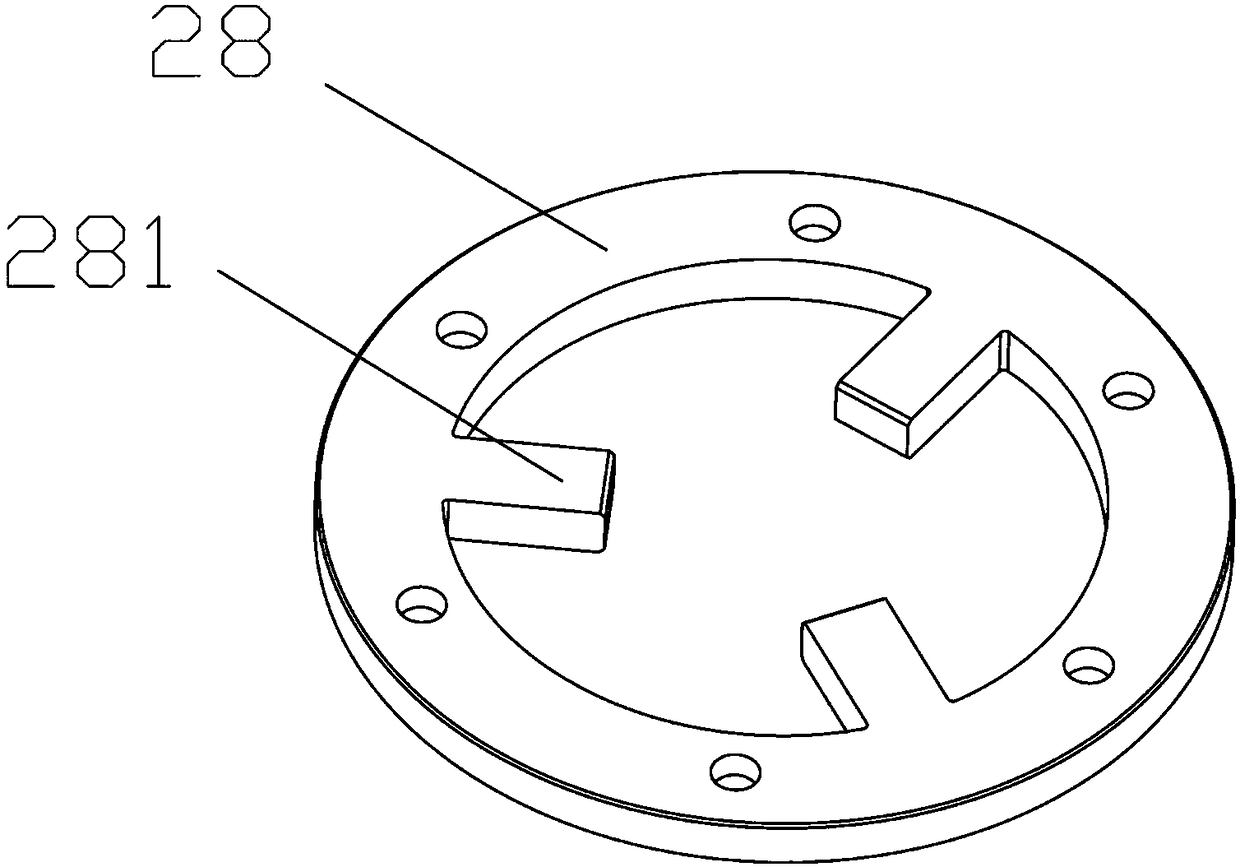

[0031] The clamping assembly 2 includes a fixing seat 21 arranged on the bottom plate 1, three clamping jaw grooves 22 evenly opened on the fixing seat 21 with the center of the fixing seat 21 as a reference, and a first jaw groove 22 slidably arranged in the clamping jaw groove 22. The clamping jaw 23, the second clamping jaw 24 connected to the driving cam 25 provided on the first clamping jaw 23 through the elastic adjusting body 5 and slidably disposed on the first clamping jaw 23, and the second clamping jaw 24 rotatably disposed on the fixing base 21 The turntable 3 of the upper part is provided with a driving waist groove 31 that cooperates with the driving cam 25 and is connected to the cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com