Fast replacement structure for bottle blowing machine mold

A bottle blowing machine and mold technology, which is applied to household appliances, other household appliances, household components, etc., can solve the problems of equipment wear, inconvenience and low efficiency, and achieve convenient operation, improve work efficiency, and quickly lock and unlock. effect of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

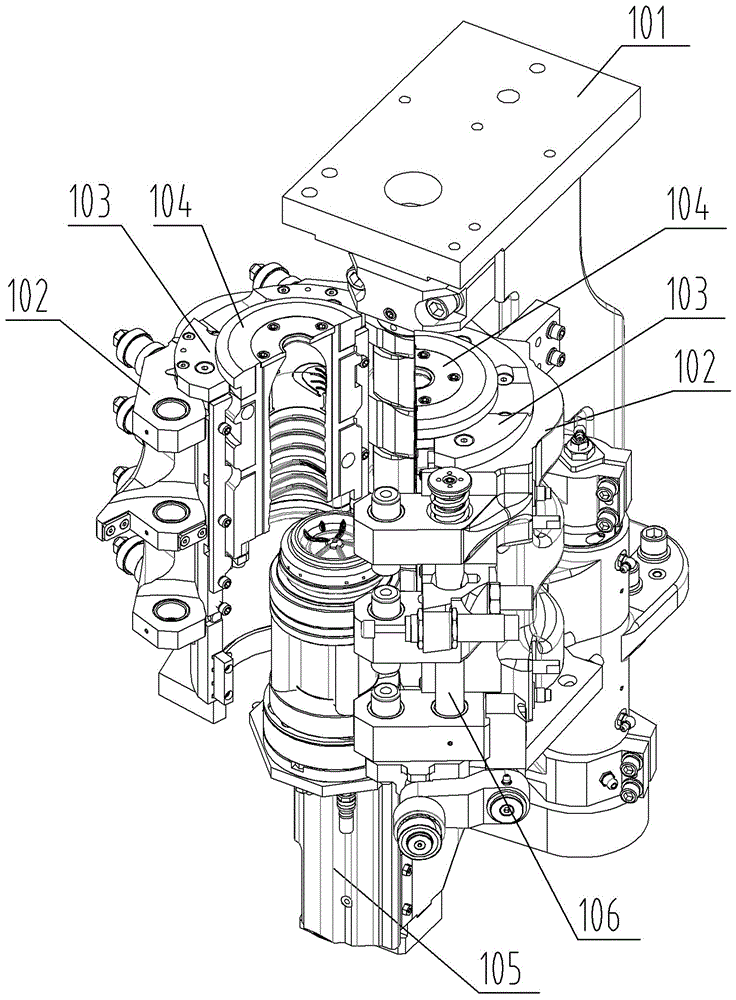

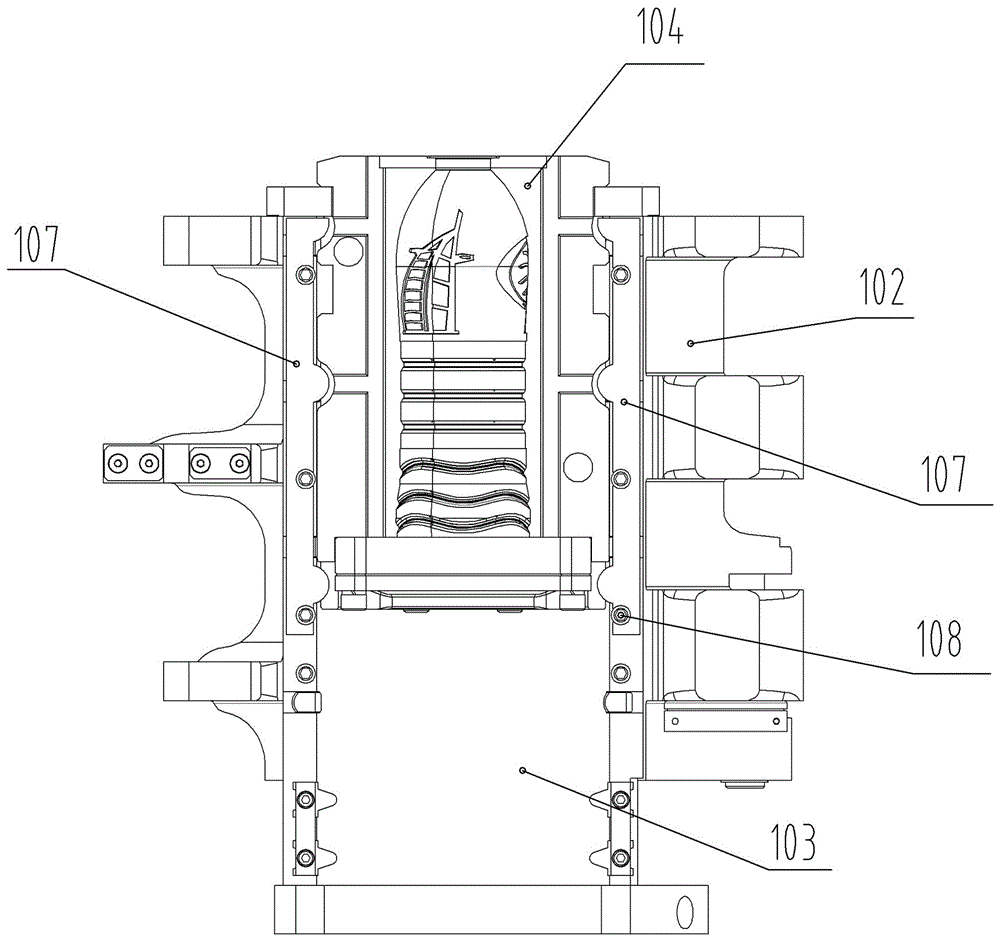

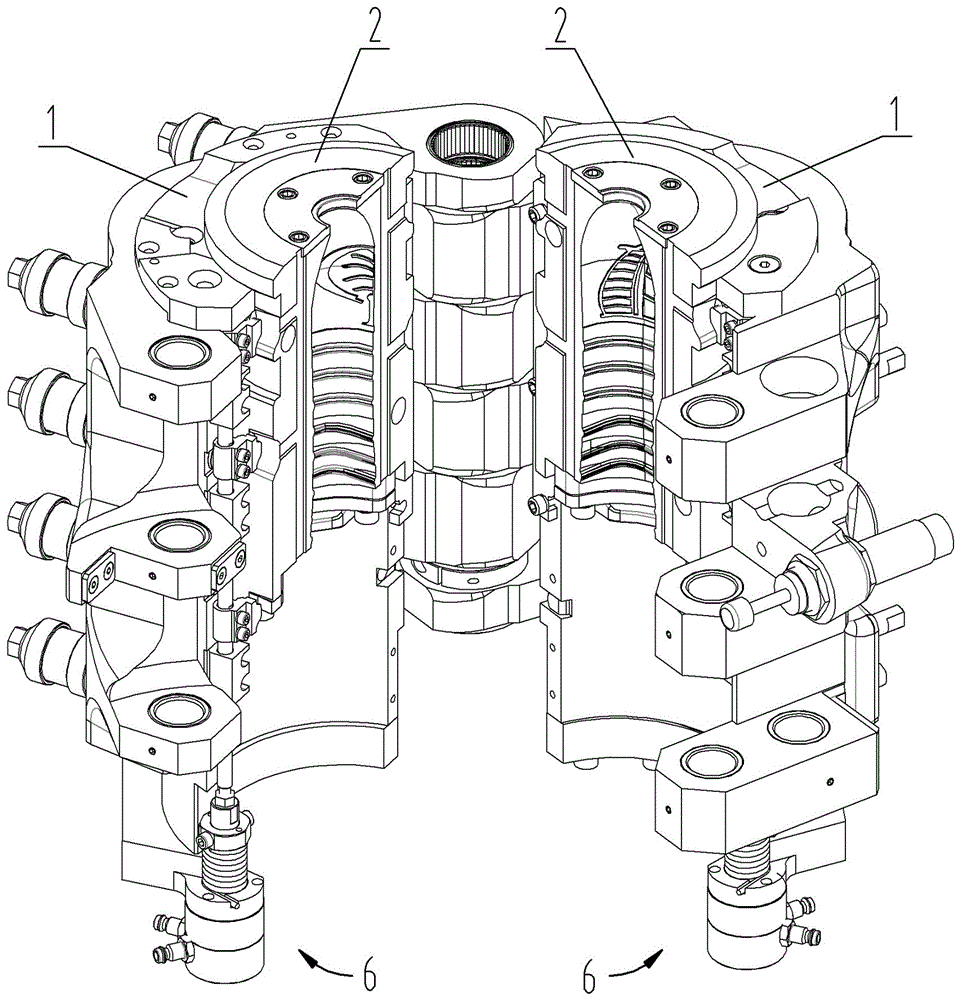

[0013] A mold quick replacement structure for a bottle blowing machine, comprising a middle mold cover 1 fixedly installed on a mold base, and a forming mold 2 jointly forming a bottle forming cavity. Block 3, connecting rod 4 movably installed on the mounting block, pressing block 5 matching the slot on the forming mold, the pressing block is installed on the connecting rod, and the connecting rod can drive the pressing block into the forming mold The draw-in slot and press against it to fix the forming mold, and the driving mechanism 6 that drives the movement of the connecting rod, the driving mechanism drives the pressing block to enter or leave the drawing-in groove of the forming mold through the connecting rod. The replacement structure can quickly complete the locking and unlocking of the forming mold through the cooperation of the clamping groove and the pressing block. The operation is extremely convenient and the working efficiency is greatly improved.

[0014] In t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap