Sheet-fed printing material cold ironing film-saving unit and its cold ironing method, cold ironing film-saving device

A technology for printing materials and film units, applied in printing, printing presses, gold powder printing, etc., can solve the problems of increasing use costs and wasting cold foil materials, and achieves the effect of saving aluminum resources, saving cold foil, and reducing material costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The embodiments of the present invention will be described in detail below:

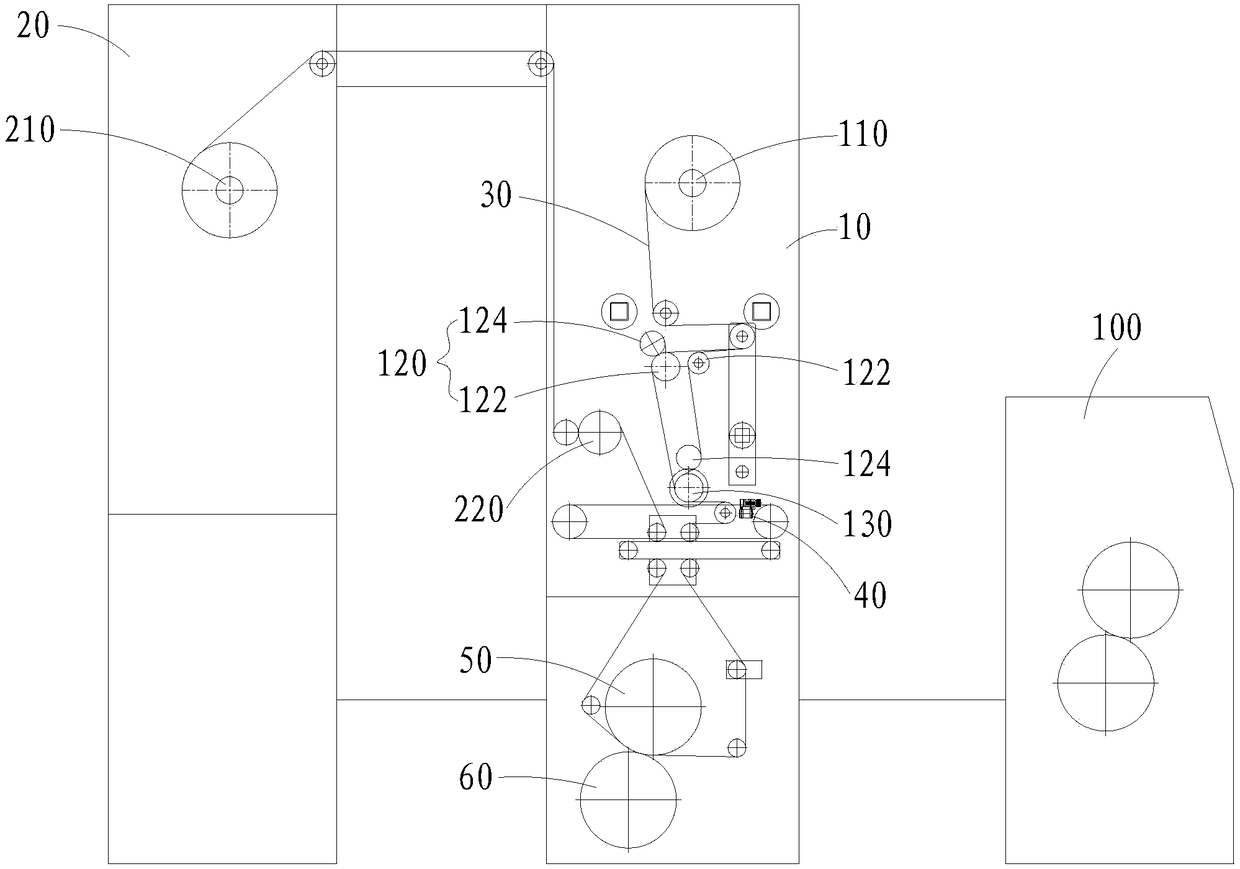

[0031] Such as figure 1 As shown, a single-sheet printing material cold foil saving unit includes an unwinding mechanism 10, a winding mechanism 20, and a control system. The unwinding mechanism 10 includes an unwinding roller 110 for unwinding at least two rolls of cold foil 30 , And at least two first pulling mechanisms 120 for pulling the corresponding rolls of cold foil 30, the winding mechanism 20 includes a winding roller 210 for winding at least two rolls of cold foil 30, the unwinding roller 110 and The winding rollers 210 are all slip shafts, and the unwinding mechanism 10, the winding mechanism 20, and the first traction mechanism 120 are electrically connected to the control system. Specifically, the unwinding roller 110 and the winding roller 210 may be driven by servo or magnetic powder. In this embodiment, the unwinding roller 110 is driven by a second servo motor, and the winding r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com