A calcium sulfate whisker reinforced toughened polylactic acid composite material and preparation method thereof

A calcium sulfate whisker, reinforcement and toughening technology, applied in the field of polylactic acid, can solve the problems of low impact toughness, limited application fields, and poor flexibility of PLA

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

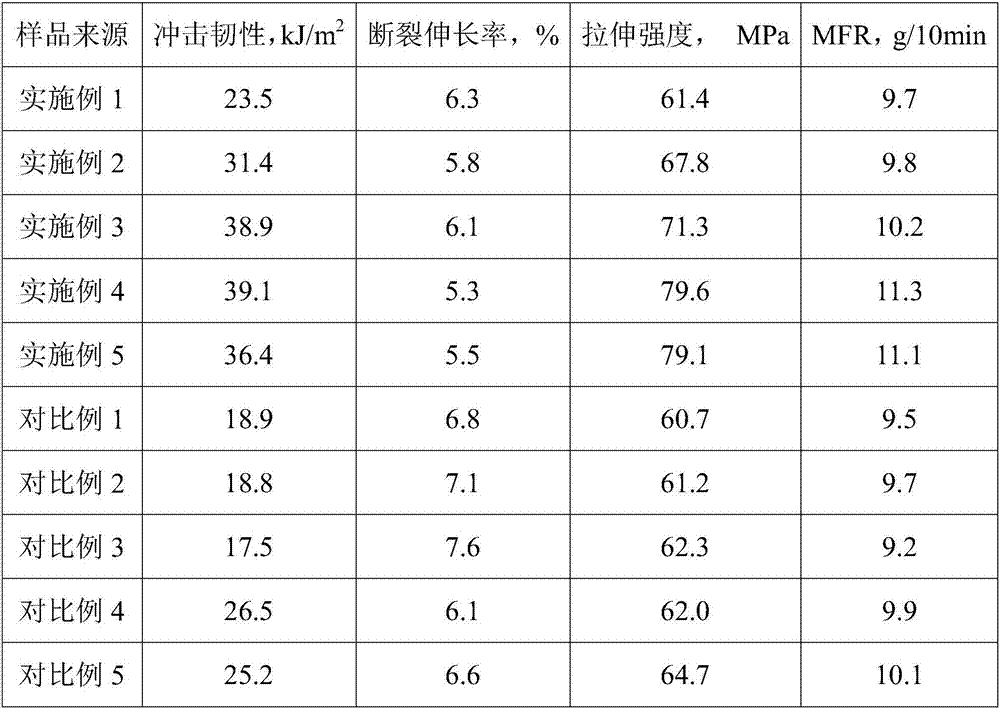

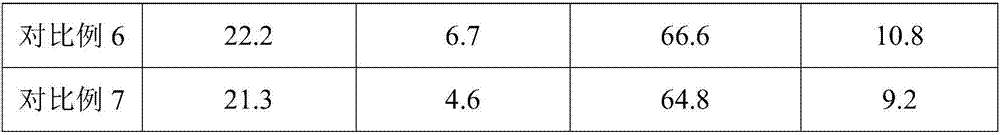

Examples

Embodiment 1

[0027] A calcium sulfate whisker-reinforced and toughened polylactic acid composite material proposed by the present invention, its raw materials include by weight percentage: polylactic acid 89%, composite masterbatch 10%, Irganox1010 0.5%, Irgafos168 0.5%;

[0028] The melt index of polylactic acid is 10g / 10min, and the density is 1.25g / cm 3 .

[0029] The preparation method of the composite masterbatch is as follows: dissolve polylactic acid in tetrahydrofuran, then add surface-treated calcium sulfate whiskers, the weight ratio of surface-treated calcium sulfate whiskers to polylactic acid is 1:2, stir for 3 hours to obtain a mixed Suspension: Pour the mixed suspension into absolute ethanol for precipitation, then wash, freeze-dry, and pulverize to obtain a composite masterbatch; in the composite masterbatch, the content of calcium sulfate whiskers after surface treatment is 50 wt%.

[0030] The preparation method of the surface-treated calcium sulfate whiskers is as follo...

Embodiment 2

[0033] A calcium sulfate whisker-reinforced and toughened polylactic acid composite material proposed by the present invention, its raw materials include by weight percentage: polylactic acid 79%, composite masterbatch 20%, Irganox1010 0.5%, Irgafos168 0.5%;

[0034] The melt index of polylactic acid is 20g / 10min, and the density is 1.25g / cm 3 .

[0035] The preparation method of the composite masterbatch is as follows: dissolve polylactic acid in tetrahydrofuran, then add surface-treated calcium sulfate whiskers, the weight ratio of surface-treated calcium sulfate whiskers to polylactic acid is 1:2, and stir for 4 hours to obtain a mixed Suspension: Pour the mixed suspension into absolute ethanol for precipitation, then wash, freeze-dry, and pulverize to obtain a composite masterbatch; in the composite masterbatch, the content of calcium sulfate whiskers after surface treatment is 50 wt%.

[0036] The preparation method of the surface-treated calcium sulfate whiskers is as f...

Embodiment 3

[0039] A calcium sulfate whisker-reinforced and toughened polylactic acid composite material proposed by the present invention, its raw materials include by weight percentage: polylactic acid 69%, composite masterbatch 30%, Irganox1010 0.5%, Irgafos168 0.5%;

[0040] The melt index of polylactic acid is 12g / 10min, and the density is 1.25g / cm 3 .

[0041] The preparation method of the composite masterbatch is as follows: dissolve polylactic acid in tetrahydrofuran, then add surface-treated calcium sulfate whiskers, the weight ratio of surface-treated calcium sulfate whiskers to polylactic acid is 1:2, and stir for 4 hours to obtain a mixed Suspension: Pour the mixed suspension into absolute ethanol for precipitation, then wash, freeze-dry, and pulverize to obtain a composite masterbatch; in the composite masterbatch, the content of calcium sulfate whiskers after surface treatment is 50 wt%.

[0042] The preparation method of the calcium sulfate whisker after surface treatment ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com