Rapid low-risk station tunnel digging method

A tunnel excavation, low-risk technology, applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve the problems of difficult construction, high consumption of temporary supports, and increased project cost, so as to reduce the trouble of measuring and setting out lines, avoid Construction difficulties and risks, the effect of accelerating construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with accompanying drawing:

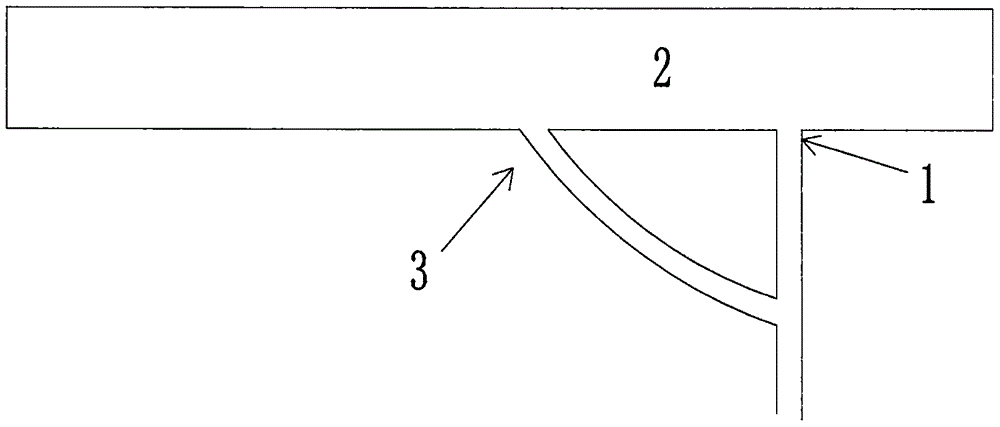

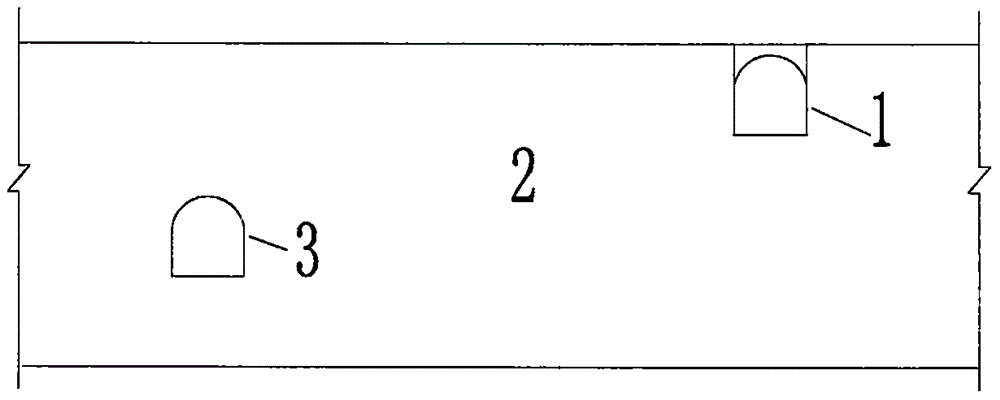

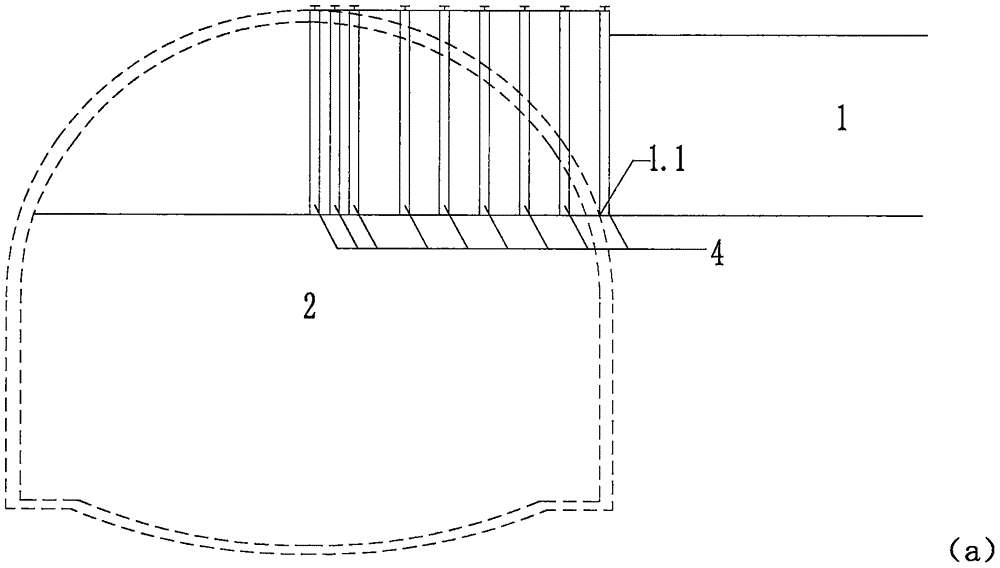

[0040] Such as Figure 1 to Figure 12 Shown: the present invention comprises the conversion construction of main construction channel 1 and station tunnel 2, the conversion construction of auxiliary construction channel 3 and station tunnel 4 and the excavation support method of station tunnel 2,

[0041] The conversion construction of described main construction channel and station tunnel comprises the following steps:

[0042] (1) At the interface position 1.1 of the main construction passage 1 and the outer side of the station tunnel 2, a door-shaped steel arch 4 is set up, and the width of the main construction passage 1 remains unchanged (that is, the width of the main construction passage 1 remains unchanged), and the top is raised to the same level as The vaults of station tunnel 2 are even;

[0043] (2) Parallel excavation according to the enlarged section of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com