Condenser end socket structure with muffling function

A condenser and head technology, which is applied in the field of heat exchange devices, can solve the problems of limited space, insignificant effect of the muffler, and difficulty in meeting the layout requirements of the limited space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is described in more detail below in conjunction with accompanying drawing example:

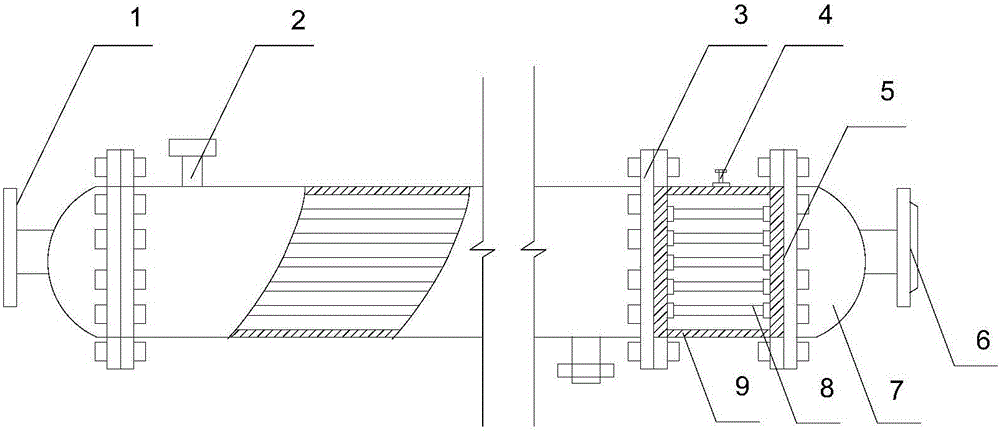

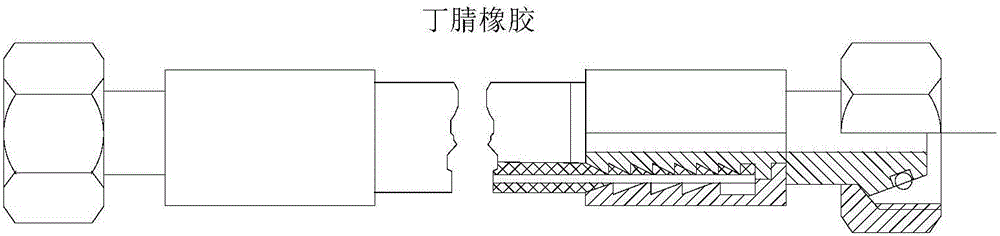

[0017] combine Figure 1-2 , The present invention includes flange A group 3, inflation valve 4, flange B group 5, rubber hose 8, pipe box 9 and so on. The material of the rubber hose 8 is nitrile rubber and it is arranged in a cylindrical structure. The nitrile rubber is processed into a shape with a thickness of 2mm in the middle and a thickness of 3mm at both ends. The pulsating liquid responds sensitively, and the thickening at both ends is conducive to fixing the rubber hose 8, which can ensure the structural strength of the rubber hose 8. Both sides of the rubber hose are connected with screw heads, which can be matched with the threaded holes on the flange A group 3 and the flange B group 5. When installing, polyethylene tape must be wrapped inside the thread to ensure sealing. When installing flange A group 3 and flange B group 5, gaskets should be insta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com