Sample conveying device, sample pretreatment system, analysis system and sample inspection automation system

A sample and main conveying technology, applied to conveyors, analytical materials, mechanical conveyors, etc., can solve the problem of processing speed reduction and achieve the effect of reducing the number of power sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

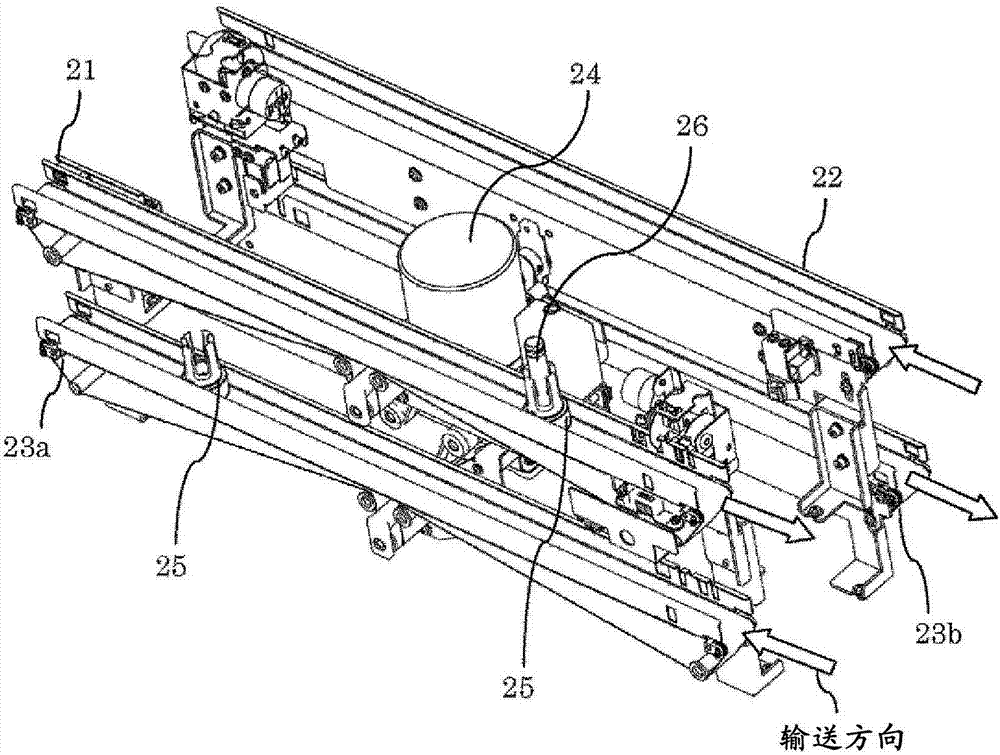

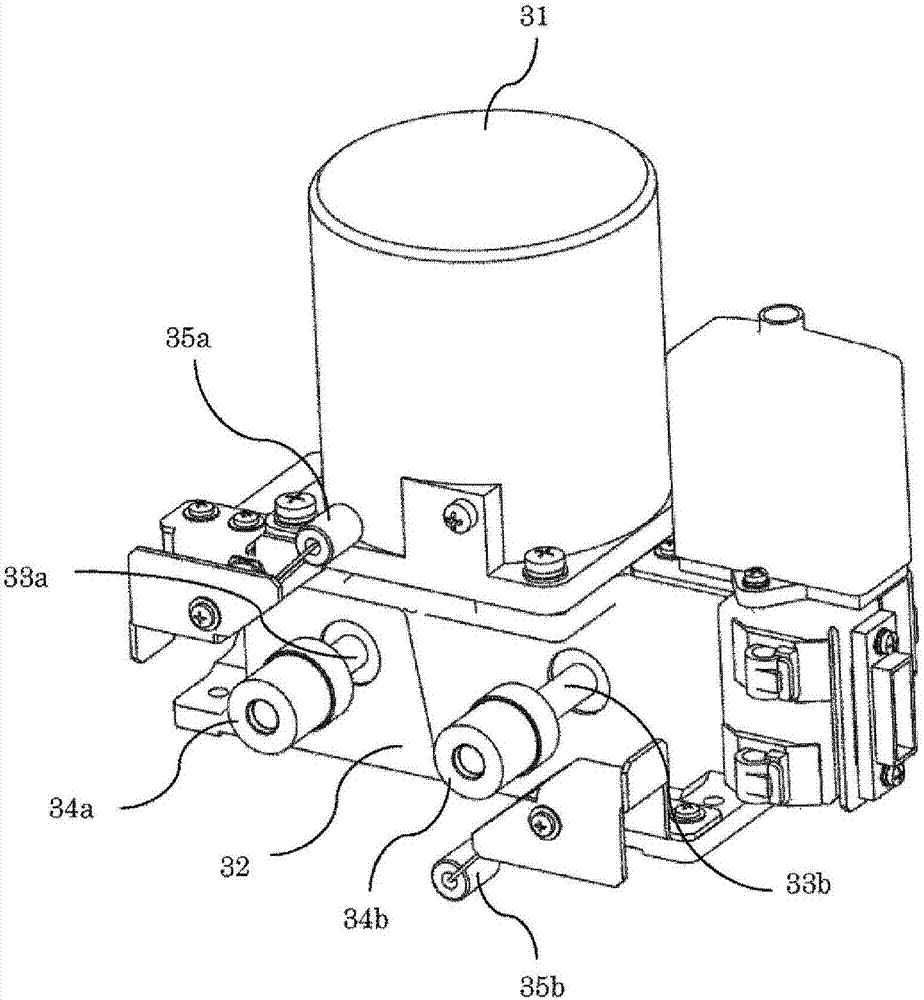

[0017] Next, an embodiment of the present invention will be described using the drawings.

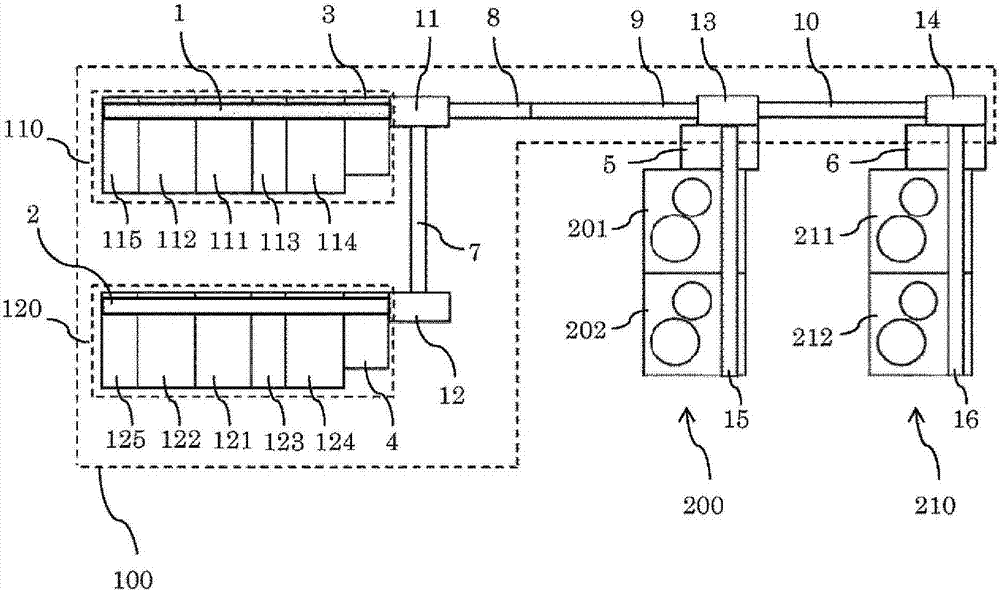

[0018] figure 1 It is a configuration diagram of an automated sample inspection system including the sample pretreatment system and the analysis system of the present embodiment. In addition, since the system structure differs according to the scale of a facility, and since there exist many combinations, one structure is demonstrated in this embodiment.

[0019] like figure 1 As shown, the sample inspection automation system 100 has a structure that connects pre-processing systems 110, 120 and multiple (two in this embodiment) analysis systems 200, 210 through conveying line units 7, 8, 9, 10. The systems 110 and 120 are used to implement the processing required before the sample analysis, and the analysis systems 200 and 210 are used to perform the analysis processing of the sample after the pre-processing is completed. In addition, in the present invention, the above-mentioned samp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com