Pre-loosening feeding device for formed machine fibers

A technology of feeding device and filament, which is applied in the application, tobacco, smoke oil filter and other directions, can solve the problems of uneven thickness of tow formation, increased adhesion, etc., to ensure the use effect, reduce the probability of waste, avoid The effect of inaccurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with embodiment the present invention is described in further detail:

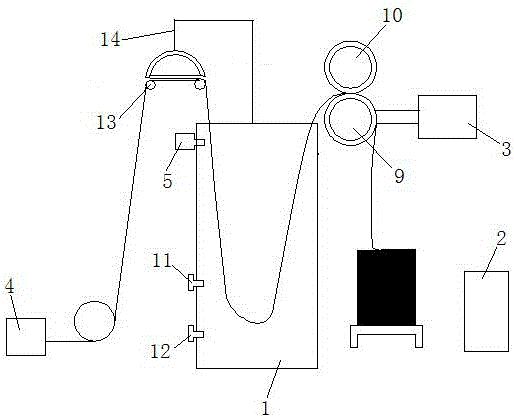

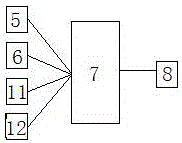

[0022] Such as figure 1 , 2 As shown, the wire pre-drawing and feeding device of the forming machine includes the transmission mechanism of the tow, the storage box 1, the on-line monitoring mechanism and the control cabinet 2 of the tow arranged in the storage box 1, and the storage box 1 is arranged on the transmission mechanism and the wire Between the 4 entrances of the forming machine of the bundle, the storage box 1 is a closed cuboid empty box structure, the two ends of the upper surface of the storage box 1 are provided with a tow inlet and a tow outlet, and the storage box 1 between the tow inlet and the tow outlet There is a space for the tow to sag inside. Before the machine wire enters the forming machine 4, it is stored in the storage box 1. The machine wire is pulled by its own gravity, and the compacted machine wire is realized by pulling. Recover the loose stat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com